How to choose a webbing cutting machine1 for your factory?

If you’re frustrated with slow cutting speeds, messy edges, and high labor costs, you’re not alone.

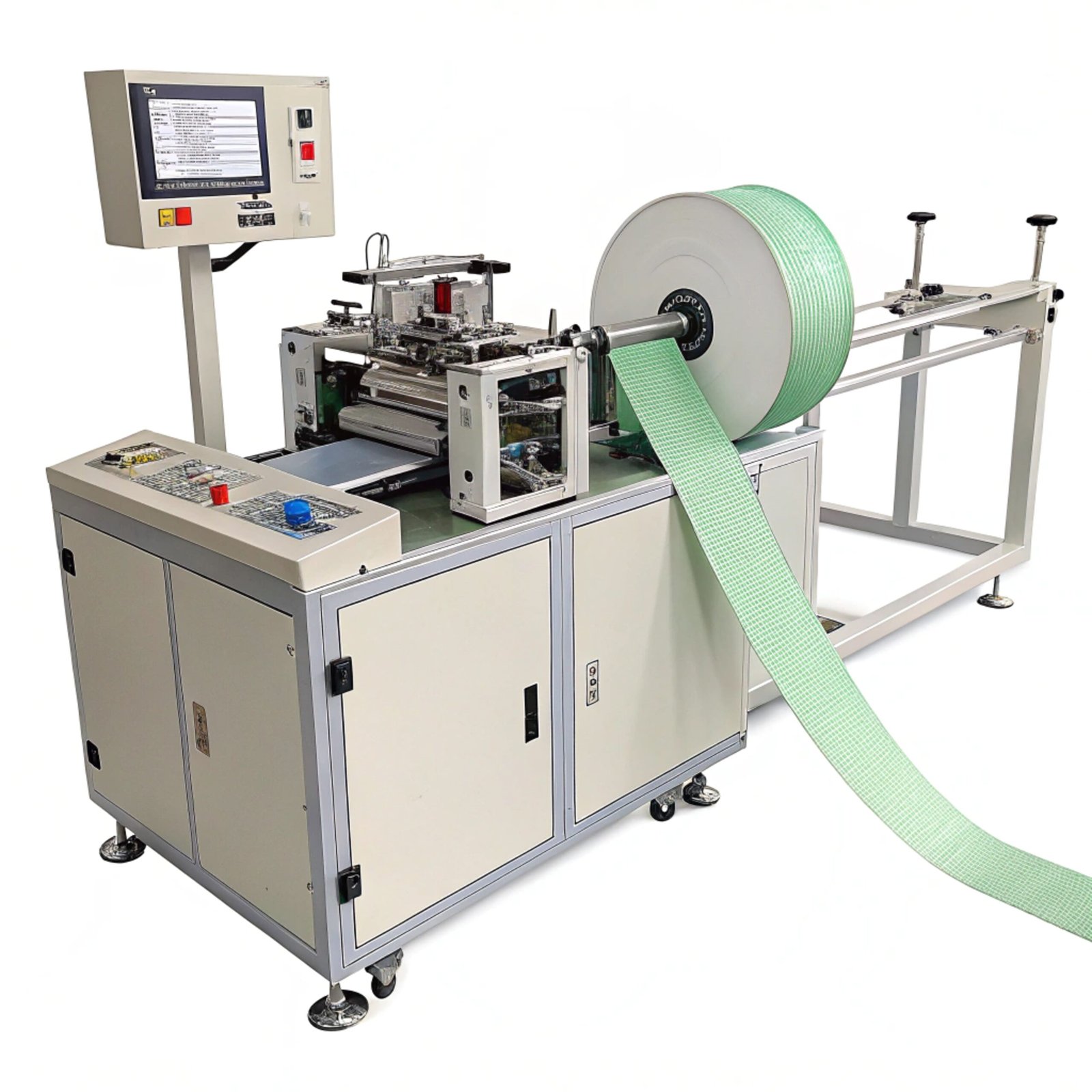

The best webbing cutting machine1 for your factory should match your material types, cutting styles, and production volume—while helping you save labor and improve efficiency.

Choosing the right machine can directly affect your lead time, product quality, and customer satisfaction. So, it’s worth understanding your options before investing.

What are the types of webbing cutting machines?

Many factory owners waste money by buying the wrong machine model for their specific needs.

Webbing cutting machines come in various types, including hot and cold cutters, ultrasonic cutters, rotary bevel cutters, and programmable machines for different shapes. Each has its own advantages for specific materials.

Common Types of Webbing Cutting Machines

| Machine Type | Cutting Method | Ideal For | Heat Sealing? |

|---|---|---|---|

| Hot Cutting Machine | Heated Blade | Nylon, Polyester Webbing | Yes |

| Cold Cutting Machine | Sharp Blade | Cotton, Paper, Soft Materials | No |

| Ultrasonic Cutting Machine | Ultrasonic Vibration | Synthetics, Thin Webbing | Yes (Clean Cut) |

| Round Shape Cutting Machine | Mechanical Die | Elastic Bands, Round Webbing | Optional |

| Programmable Bevel Cutting Machine | Motorized Bevel Blade | Strips Needing Angled Edges | Optional |

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we design and manufacture all the above machines. Our bestsellers include the webbing ribbon cutting machine, rotary bevel cutting machine, and hot and cold cutting machines, widely used across textile, printing, and packaging industries.

Choosing Based on Material

If you cut synthetic webbing like nylon or polyester, a hot cutting machine is essential to seal edges. For paper or soft materials, choose a cold cutting machine to avoid burning. Need perfect angles? A bevel cutting machine will save you tons of time.

Also, consider machine speed and automation level. Entry-level machines are cheaper but require manual loading. Advanced machines with automatic feeding, cutting, and stacking can double your productivity.

How does a webbing punching holes cutting machine2 improve productivity?

Manually punching holes in webbing takes time and often causes inconsistency and errors.

A webbing punching holes cutting machine2 integrates precise punching and cutting in one workflow—boosting speed, consistency, and reducing manual labor.

Key Features of a Webbing Punching Holes Cutting Machine

A high-quality webbing punching holes cutting machine from Suzhou Haoxinhe Electrical Equipment Co., Ltd. integrates cutting and punching seamlessly. These machines are designed to handle:

- Pre-programmed punch patterns

- High-speed synchronized cutting

- Adjustable hole spacing and diameter

- Clean, sealed edges (in hot punching models)

You no longer need to run two separate processes or hire two different operators. Our automatic punching cutting machine reduces operation time by up to 50%, and significantly lowers the defect rate caused by manual misalignment.

Use Cases Across Industries

For HVAC Duct Manufacturers:

Need perfectly spaced webbing straps with holes for fixing? One operator using a webbing punching holes cutting machine can prepare 500+ straps per hour—ready for assembly.

For Bag Manufacturers:

Handle loops and strap components often require consistent hole placements. Automating this process helps maintain product standards and reduces rework.

ROI Consideration

If your factory currently uses manual labor or basic tools, switching to a programmable punching cutting machine can yield ROI within 3 to 6 months due to labor savings, reduced waste, and faster output.

What should I consider when sourcing a webbing cutting machine from China?

Many buyers have faced delays, fake certificates, and poor communication when sourcing from overseas.

To safely and smartly source a webbing cutting machine from China, focus on supplier reliability3, certifications, customization capability, and clear shipping terms.

Key Considerations Before Placing an Order

✅ Supplier Verification

Choose a supplier with real factory credentials. Suzhou Haoxinhe Electrical Equipment Co., Ltd. is a high-tech enterprise with 5 production lines and exports mainly to Europe, Singapore, and North America. You can verify our Alibaba storefront or request a live factory video tour.

✅ Product Customization

Does the supplier offer custom features? We specialize in custom cutting solutions, whether you need a PVC edge banding cutting machine, protective foam cutting machine, or bubble wrap cutting machine—we’ve got you covered.

✅ Certifications and Quality Control

Ask for real CE certificates, internal QC processes, and test videos. At Haoxinhe, each machine undergoes full testing and aging before shipping.

✅ Logistics and Lead Time

Choose factories with fast delivery guarantees. Delayed machines mean lost sales seasons. We offer 7-15 day production time for most models and support shipping via sea or air.

✅ Communication

Language and time zones can lead to miscommunications. At Haoxinhe, I personally oversee key overseas orders to ensure prompt response and clarity. You can email me at cherryhaoxinhesz@gmail.com for any queries.

Red Flags to Watch Out For

- Very low prices with no tech support

- No videos or real photos of their workshop

- Poorly translated communication

- No warranty or after-sales support

Conclusion

Choosing the right webbing cutting machine depends on your material, process, and sourcing strategy—make sure it fits your needs today and scales with you tomorrow.

Insights:

A webbing cutting machine1 boosts efficiency when matched correctly to your material and volume. For factories handling repetitive punching tasks, a webbing punching holes cutting machine2 offers speed, precision, and ROI. When sourcing from China, verify suppliers carefully and choose proven manufacturers like Suzhou Haoxinhe Electrical Equipment Co., Ltd.

Explore this link to find expert reviews and comparisons of webbing cutting machines tailored for factory needs. ↩ ↩ ↩

Discover how this machine can streamline your production process and enhance efficiency in your factory. ↩ ↩ ↩

Learn about the key factors to ensure you choose a reliable supplier for your machinery needs, avoiding common pitfalls. ↩