How is AI transforming the efficiency of aluminium foil cutting machines in industrial use?

Human monitoring isn’t fast enough to detect micro-errors or predict failures before they happen.

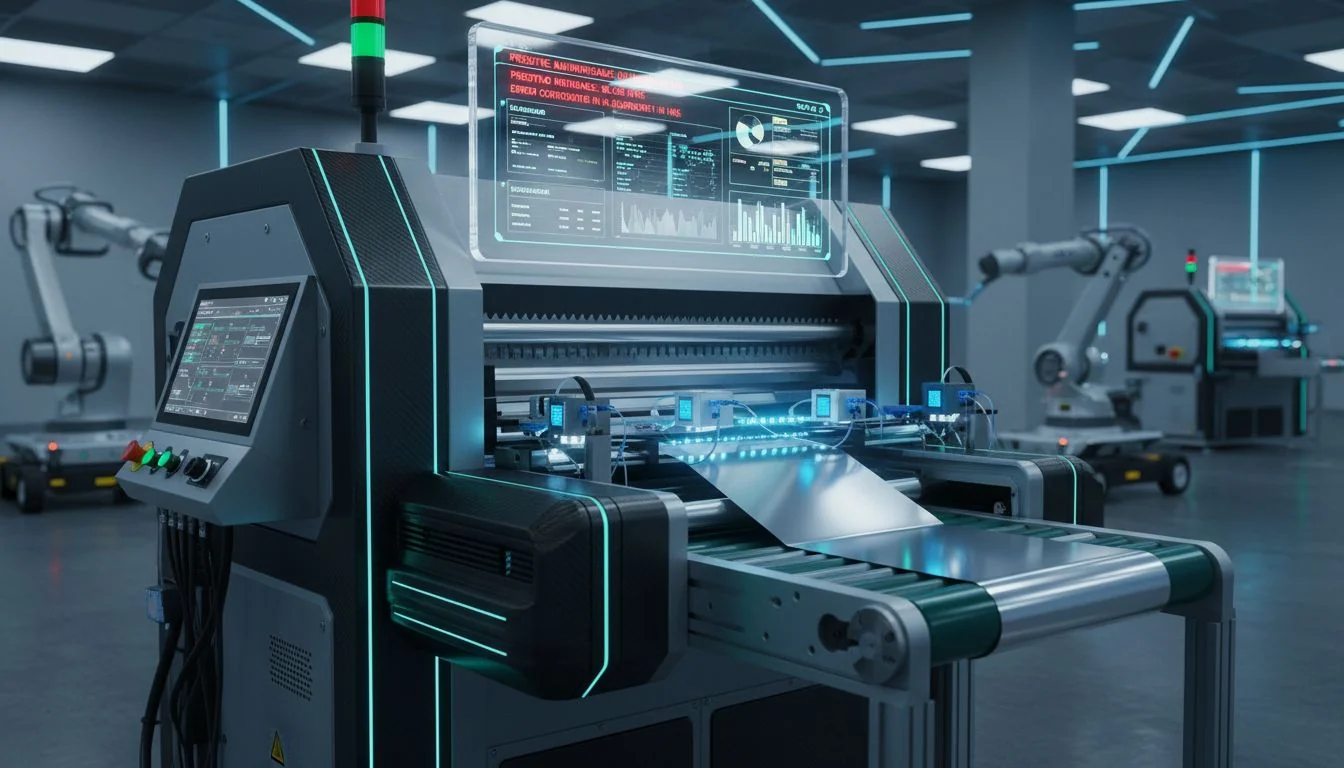

AI is transforming aluminium foil cutting machines by enabling real-time optimization, predictive maintenance, and intelligent error correction—leading to higher uptime and reduced operational costs.

In industrial production, milliseconds matter. One faulty feed or one blade misalignment can halt an entire packaging line. That’s why manufacturers are turning to AI—not just to automate, but to optimize and predict. Let’s explore how this shift is already happening.

What AI-based predictive maintenance tools1 are available for foil cutting equipment?

Reactive maintenance leads to lost hours, while scheduled maintenance often replaces healthy parts.

AI-based predictive maintenance tools1 use sensors and machine learning to monitor wear, temperature, vibration, and cut precision—alerting you before failures occur.

Instead of waiting for the machine to break down or replacing components too early, predictive maintenance tells you exactly when a part is about to fail. This minimizes downtime and saves unnecessary part costs.

How AI predicts failures in aluminium foil cutting machines

AI systems collect real-time operational data through:

- Vibration sensors on motors and blades

- Temperature sensors near motors and blade housing

- Optical sensors checking for cut accuracy

- Tension monitoring on rollers and feeders

This data feeds into algorithms trained to spot abnormal patterns. When readings deviate from the baseline, the system sends alerts—via a control panel, app, or integrated PLC screen.

Key benefits of AI-driven maintenance

| Feature | Benefit |

|---|---|

| Real-time condition monitoring | Detects stress, overheating, or vibration anomalies before failures occur |

| Failure prediction | Alerts operators days or hours before a part wears out |

| Optimized maintenance timing | Avoids unnecessary downtime by replacing only worn components |

| Historical analytics | Tracks performance trends to improve usage patterns and operator behavior |

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we are incorporating smart diagnostics into our computer tube cutting machines, rotary bevel cutting machines, and webbing tape cutting machines. These systems integrate with factory MES or PLC systems for real-time AI insights.

Common AI predictive tools in use today

1. Edge-based analytics

- AI software installed directly on the machine’s control board

- Useful for real-time alerts even without cloud connectivity

2. Cloud-based AI dashboards

- Aggregate data from multiple machines

- Provide long-term analytics and maintenance schedules

3. Mobile app integration

- Sends push notifications to operators

- Helps small teams manage multiple machines remotely

Our bubble wrap cutting machines and hot and cold cutting machines now come with optional smart maintenance modules. These modules are already helping our clients in Germany and Singapore reduce unplanned downtime by over 50%.

Real-world impact: One manufacturer’s results

A packaging plant in France used our automatic punching cutting machine with AI monitoring for 3 months. Their outcomes:

- Machine failure alerts increased by 90% (more issues caught early)

- Emergency repairs dropped by 70%

- Blade replacements were done 25% more efficiently (only when needed)

This resulted in $12,000 annual savings just from avoided downtime and fewer technician callouts.

How AI improves overall efficiency in foil cutting

AI doesn’t stop at maintenance—it also controls how the machine cuts, feeds, and adjusts in real time.

Examples of AI-driven performance improvements

🧠 Adaptive speed control

AI adjusts cutting speed based on material thickness, humidity, and roll tightness to avoid tearing.

🧠 Intelligent blade wear detection

AI monitors blade performance and tells operators when to replace it—before cut quality declines.

🧠 Auto calibration

Smart systems learn the best feed rate and tension settings for each batch and adjust automatically.

🧠 Cut quality scanning

AI-linked cameras can detect imperfect edges, burrs, or undercuts and reject them automatically.

At Suzhou Haoxinhe, our cutting solutions like the PVC edge banding cutting machine and protective foam cutting machine are moving toward AI-integrated control panels. These help new operators work like seasoned pros, minimizing training time and boosting yield from day one.

Why AI is the future of foil cutting

In high-volume industries—food packaging, electronics insulation, or pharmaceuticals—manual tweaks are too slow. AI delivers:

- Consistent quality

- Lower labor reliance

- Reduced scrap rates

- Better scheduling through predictive downtime tracking2

Conclusion

AI turns aluminium foil cutters from passive tools into intelligent systems—maximizing every cut, every shift.

Insights:

AI-powered systems are revolutionizing aluminium foil cutting by enabling predictive maintenance, intelligent blade management, and real-time production optimization. At Suzhou Haoxinhe Electrical Equipment Co., Ltd., our machines—including the hot and cold cutting machine and rotary bevel cutting machine—integrate AI-ready modules that help factories cut smarter, reduce waste, and minimize unplanned downtime across global production lines.