How Bubble Wrap Cutting Machines Work: A Step-by-Step Breakdown?

Bubble wrap is essential for protective packaging — but cutting it manually is slow and wasteful.

A bubble wrap cutting machine automates the process, slicing wrap to exact sizes with clean edges and minimal waste, all at high speed.

In this article, I’ll walk you through how these machines work — step by step — and how each function streamlines packaging operations.

Why automate bubble wrap cutting?

Manual cutting with scissors or blades takes time, creates inconsistent lengths, and damages bubbles.

Automated machines ensure clean cuts, repeatable sizes, and higher output with lower labor — critical for packaging departments in electronics, furniture, appliances, logistics, and more.

Core Benefits

- Consistent sheet sizes

- Lower material waste

- Faster production rates

- Less worker fatigue

- Clean packaging presentation

Now, let’s look at how the machine actually performs the job — from start to finish.

Step 1: Load the Bubble Wrap Roll

Every machine starts with a fresh roll — usually between 300mm and 1500mm wide, depending on the product.

You manually or automatically load the roll onto the rear shaft, where it’s tensioned and aligned.

Machine Features at This Stage

- Adjustable roll holders for various core sizes

- Brake system or tension rollers to prevent shifting

- Sensor alignment to keep wrap feeding straight

- Optional ESD-safe versions for electronics packaging

Once the roll is loaded and tensioned, the operator moves to the control panel.

Step 2: Set the Cut Length

Using the machine’s control panel (usually a touchscreen), you program the length for each cut.

Lengths can be set from 200mm up to 3000mm+ depending on machine size, with presets for standard jobs.

Programming Options

- Single Length Mode: One repeatable cut size

- Batch Mode: Mix of preset lengths for different products

- Timed Mode: Cut based on interval if used inline

- Manual Feed: For test cuts or custom wrapping

Once the cut program is confirmed, the feed system activates.

Step 3: Automatic Feeding and Alignment

The machine pulls the bubble wrap from the roll using powered feed rollers or belts.

It feeds to the programmed length, automatically measuring the distance with sensors or encoders.

Key Components

- Servo motors for smooth motion

- Anti-slip rollers to grip wrap evenly

- Sensors to avoid misfeeding or bunching

- Adjustable speed for different roll densities

This ensures precise measurement before the blade moves in.

Step 4: Cutting the Bubble Wrap

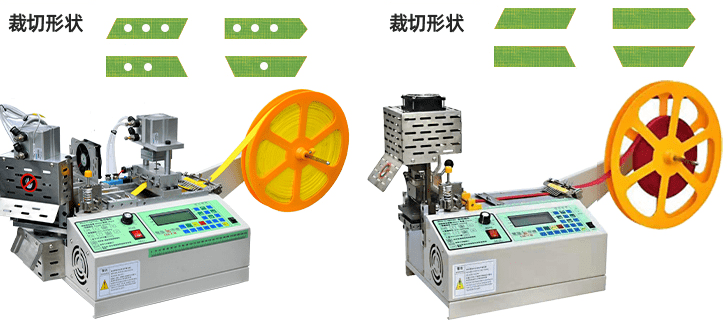

Once the correct length is reached, the machine engages its blade — either cold or hot — to perform the cut.

Cold cutting preserves bubble integrity, while hot cutting can seal edges for specialty applications.

Blade Options

| Type | Use Case |

|---|---|

| Cold Blade | Standard wrap, no odor, clean edge |

| Hot Blade | Edge sealing, PVC or foam-based wrap |

| Perforation Tool | Easy tear-off sheets (optional add-on) |

Advanced models use pneumatic or servo-driven blades for clean, vibration-free cuts.

Step 5: Dispense the Cut Sheet

Once the wrap is cut, the machine dispenses the sheet into a tray, onto a conveyor, or rolls it onto a liner — depending on setup.

Operators can now grab the pre-sized sheet and wrap products directly — no trimming required.

Output Options

- Collection bin

- Stacker or shelf tray

- Inline conveyor for automated packing

- Roll rewinder for roll-to-roll operations

Some models include counters to track how many sheets were cut — ideal for batch fulfillment.

Step 6: Repeat and Monitor

The machine resets and repeats the process — feeding, cutting, and dispensing — until the roll ends or the operator stops the cycle.

Operators monitor the system for jams, roll ends, or cut confirmation. Most machines require minimal oversight once set.

Safety & Automation Features

- Emergency stop button

- Roll end detection

- Cut confirmation sensors

- Motor overload protection

- Optional auto-stop after batch complete

This means more output with less supervision — perfect for high-throughput operations.

What industries benefit from this process?

If you package fragile, large, or high-volume items, this machine can cut your time and cost significantly.

Common Users

- Electronics Manufacturers

- Furniture & Appliance Factories

- Glass, Lighting & Ceramics Suppliers

- 3PL & Fulfillment Warehouses

- Medical Equipment Packers

Each step in the machine’s process is designed to eliminate human error and boost packing productivity.

Why choose Suzhou Haoxinhe?

We don’t just build machines — we optimize packaging systems.

Suzhou Haoxinhe Electrical Equipment Co., Ltd. is a CE/ISO-certified manufacturer with 5 production lines and full export support for clients worldwide.

Why Clients Trust Us

- Programmable touch panel interfaces

- Custom widths and blade styles

- Cold/hot/perforated cutting options

- Fast global delivery (7–15 days)

- Multilingual support (EN, FR, CN)

- Remote setup guidance + maintenance videos

We also supply:

- Velcro dot and label cutters

- Foam and edge banding cutters

- Webbing ribbon and film cutting machines

We’re trusted by electronics OEMs, furniture exporters, packaging houses, and logistics hubs around the world.

Conclusion

A bubble wrap cutting machine takes a simple task and makes it faster, cleaner, and more scalable — transforming your packing floor from slow to seamless.

Insights

Bubble wrap cutting machines work through automatic feeding, programmable length control, precision cutting, and clean dispensing. Suzhou Haoxinhe’s models support cold or hot blades, wide rolls, and fast repetition — perfect for factories, fulfillment centers, and protective packaging at scale.