How Automatic Ribbon Cutting Machines Solve Key Production Problems?

Manufacturers wasting hours on manual ribbon cutting face mounting production delays and material waste.

Automatic ribbon cutting machines solve four major production problems: inconsistent lengths, slow output, material waste, and labor fatigue. Programmable cutting length enhances textile workflow by enabling quick changeovers, precise repeatability, and batch-specific customization without downtime.

1: Automates cutting, eliminating the need for constant manual operation.

2: Reduces labor effort while improving operational efficiency.

3: Minimizes material waste through precise, controlled cuts.

4: Performs multiple cut types for versatile production needs.

5: Enhances customization capabilities in manufacturing workflows.

These solutions transform ribbon processing from a bottleneck to a streamlined operation. Let’s examine the specific benefits.

4 Production Problems Automatic Cutting Eliminates

Manual cutting operations struggle with basic quality control as workers tire through long shifts.

Automatic cutters deliver consistent output by solving:

- Length inconsistencies from human error

- Speed limitations of manual processes

- Material waste from imprecise cuts

- Labor cost and availability issues

Problem Comparison: Manual vs Automatic

| Production Challenge | Manual Cutting | Automatic Solution |

|---|---|---|

| Length accuracy | ±3mm tolerance | ±0.5mm precision |

| Maximum output | 300 cuts/hour | 1,200+ cuts/hour |

| Material waste | 8-12% typical | 3-5% achievable |

| Operator fatigue | Significant after 2 hours | Virtually eliminated |

How Programmable Length Transforms Textile Workflow

Guillotine cutters force production pauses for length adjustments between orders.

Programmable cutting improves workflow through:

- Instant changeovers between lengths

- Digital storage of common patterns

- Batch-specific length programming

- Automatic adjustment for material stretch

Workflow Efficiency Gains

| Feature | Time Savings | Benefit |

|---|---|---|

| Preset programs | 75% faster changeovers | 4x more batches per shift |

| Memory recall | No measurement needed | Eliminates setup errors |

| Automatic compensation | 15% faster running speed | Accounts for material properties |

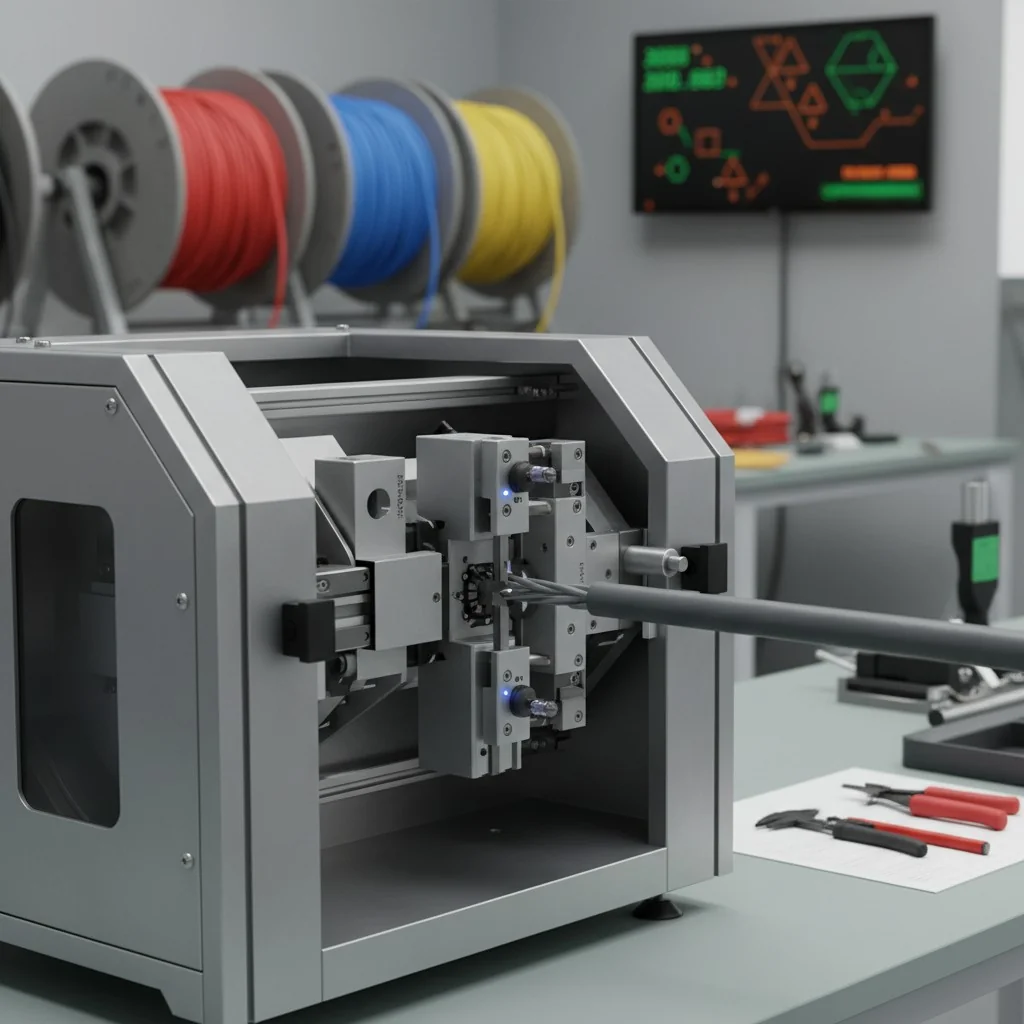

HAOXINHE Cutting Solutions in Action

Our SmartCut Pro Auto series demonstrates these advantages daily:

- For elastic ribbon producers: Programmable tension control prevents stretching during cutting

- In packaging tape plants: 2mm width tolerances maintained across 24-hour production

- At textile labels manufacturers: 150 different lengths stored for instant recall

The programmable interface lets operators:

- Save 100+ cutting recipes

- Adjust parameters during operation

- Monitor production statistics

This level of control turns cutting operations from a variable cost center into a predictable, optimized process.

Key Takeaways

Automatic ribbon cutting machines solve fundamental production constraints by:

✔ Removing human error from length measurement

✔ Operating 3-4x faster than manual methods

✔ Reducing material waste by 50% or more

✔ Enabling flexible production through programming

For textile operations running multiple ribbon types or custom orders, programmable systems provide the agility to compete in today’s fast-moving markets.

From the HAOXINHE Factory Floor

We’ve installed over 500 programmable cutting systems across three continents. The consistent feedback from manufacturers highlights three workflow improvements:

- Setup time reduction – Changing between jobs now takes minutes instead of hours

- Labor reallocation – Staff move from cutting to higher-value quality control roles

- Overtime elimination – Production targets met within standard shifts

Our CutMaster 6000 series takes this further with IoT connectivity for real-time monitoring – proving automation’s value extends far beyond the initial cutting operation.

For operations still relying on manual methods, the production and cost benefits of upgrading become apparent within the first payroll cycle. The question isn’t whether to automate, but how quickly the transition can be implemented.

Automatic ribbon cutting machines solve key production problems by providing:

High efficiency and speed: They cut ribbons rapidly (e.g., up to 110 cuts per minute), significantly increasing throughput compared to manual cutting and reducing production time.

Precise and consistent cutting: Equipped with microcomputer controls and high-precision sensors (like electronic eyes), these machines ensure exact cut lengths and widths with minimal deviation, reducing material waste and rework.

Labor cost reduction and ease of operation: Automation minimizes manual labor needs, lowering labor costs and operator fatigue. User-friendly interfaces with touchscreens or control boards simplify machine setup and monitoring.

Improved product quality: Some models provide hot knife cutting that seals edges as they cut, preventing fraying and producing clean, durable ribbon ends, enhancing product aesthetics and performance.

Versatility and customization: They accommodate various ribbon materials, widths, and cutting modes tailored to specific production needs, enabling adaptability across industries.

Safety and reliability: Automated operation with safety features reduces operator injury risks and machine downtime, ensuring stable long shifts.

In summary, automatic ribbon cutting machines tackle production bottlenecks by speeding up ribbon processing, ensuring precision and uniformity, cutting labor requirements, improving product appearance, and offering robust, adaptable, and safe operation. These benefits collectively enhance manufacturing efficiency and product quality in ribbon-related industries.