Hot & Cold Strip Cutting Machine: What’s the Difference and Who Needs It?

If your cutting machine1 burns or frays your material, it’s time to rethink your equipment.

Hot & cold strip cutting machines use different blade temperatures to deliver clean, precise cuts without damaging the material, depending on your production needs.

Not every material can handle heat, and not every job can wait. The right blade makes all the difference. Let me walk you through how I choose for my clients.

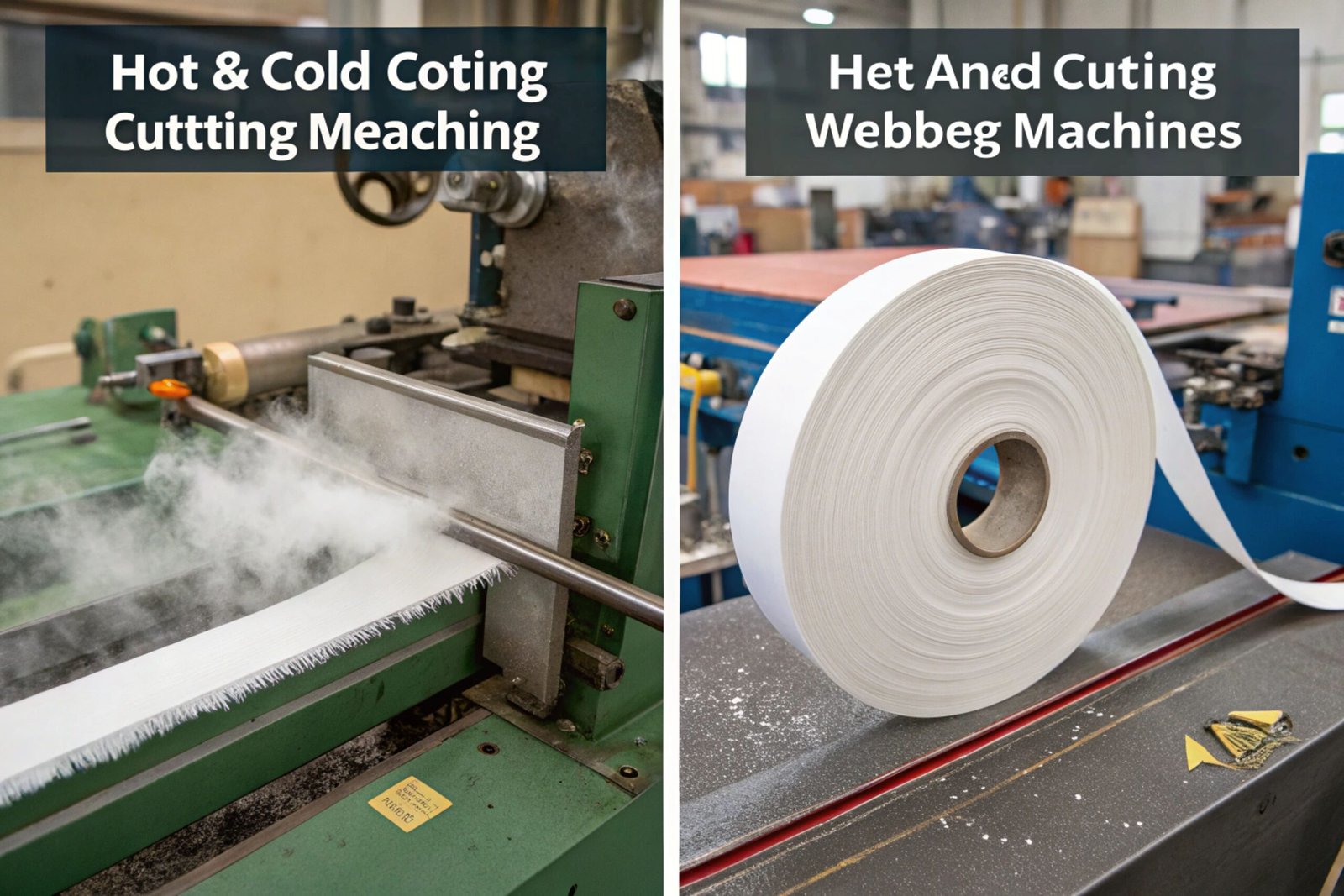

What is a Hot & Cold Strip Cutting Machine?

Sometimes the edges melt. Sometimes they must not. This machine does both.

A hot & cold strip cutting machine1 can switch between heated and unheated blades to suit different materials like nylon, polyester, PVC, foam, and more.

Suzhou Haoxinhe Electrical Equipment Co., Ltd. manufactures this kind of machine to help factories handle high-speed, accurate, and versatile material cutting. The goal is clean edges, high output, and low waste.

Why Both Functions Matter

Depending on the material, we may need sealed edges to prevent fraying (hot cutting), or we may need a neutral cut with no heat damage (cold cutting). Let’s break it down.

| Material Type | Suitable Cutting | Why |

|---|---|---|

| Nylon Webbing | Hot Blade | Seals edge to prevent fraying |

| Cotton Tape | Cold Blade | Heat would burn the edge |

| PVC Edge Banding | Cold Blade | Maintains shape and finish |

| Foam Sheets | Hot Blade | Reduces flying debris and seals foam edge |

Inside the Machine

At Suzhou Haoxinhe, our hot & cold cutting machine1s include features like:

- Programmable length and quantity

- Adjustable speed and pressure

- LCD touch screens

- Blade temperature controls

- Safety stop sensors

These are not just bells and whistles. For a buyer like Mark Chen from Canada, precision and safety are core requirements to scale his rebranding and distribution business.

What’s the difference between hot blade and cold blade webbing cutting?

Burnt edges are bad for some products. But frayed edges are worse.

Hot blade cutting melts and seals the edge; cold blade cutting uses sharp mechanical force to slice cleanly. The choice depends on your material and end-use.

Hot Blade Cutting2

A hot blade cutting machine uses heat to melt through synthetic fabrics. It seals the edge during the cut. This is essential for polyester straps, nylon webbing, or thermoplastic materials. Here’s what it looks like in action:

- Temperature reaches 300–600°C

- Edges are sealed during the cut

- No fraying, no sewing needed after

At Haoxinhe, our Hot Blade Webbing Cutting Machine is equipped with auto-feed, length control, and safety enclosures to support factories running thousands of meters per day.

Cold Blade Cutting3

Cold blade cutters are needed for materials that react poorly to heat. They offer:

- High blade sharpness

- Precision cutting down to 0.1mm

- No discoloration or burn marks

Cold cutting is ideal for cotton, paper, protective film, or PVC edge bands where appearance matters.

Why It Matters to Buyers

For clients like Mark, switching between hot and cold blades allows him to serve multiple product lines with one piece of equipment. That’s cost-effective and faster to scale.

Which industries need hot and cold cutting machine1s?

Your product line determines the cutting machine you need—not the other way around.

Industries like automotive, medical, printing, packaging, and textiles all benefit from hot and cold cutting machines due to their material flexibility.

Industry Applications

Here’s where our equipment fits:

| Industry | Materials Used | Recommended Blade |

|---|---|---|

| Printing | Paper, film | Cold Blade |

| Textiles | Nylon, polyester | Hot Blade |

| HVAC | Protective foam, insulation | Hot Blade |

| Medical | Tubing, bandages | Cold Blade |

| Packaging | Bubble wrap, edge banding | Either, based on product |

Our Bubble Wrap Cutting Machine, PVC Edge Banding Cutting Machine, and Protective Foam Cutting Machine all stem from this core technology. Customizations are available depending on the exact use case.

What Clients Should Consider

Before buying, I always ask clients three questions:

- What’s the core material you’re cutting?

- Do you need sealed or raw edges?

- What’s your daily output?

Suzhou Haoxinhe’s machines come with multilingual operation panels, CE certifications, and spare blade kits to support global buyers like Mark. Especially for those sourcing from China and reselling in Canada or Europe, certifications and delivery speed are deal-breakers.

Conclusion

Hot and cold cutting machines give you edge control, clean finishes, and flexibility for any material.

Insights

Hot and cold strip cutting machine1s use adjustable blade temperatures to handle various materials like webbing, foam, PVC, and film. Hot blades seal edges to prevent fraying, while cold blades ensure clean, burn-free cuts. Industries from printing to HVAC rely on this equipment to improve product quality and manufacturing efficiency. Suzhou Haoxinhe Electrical Equipment Co., Ltd. provides versatile, certified, and customizable cutting solutions trusted by global B2B clients.

Discover the advantages of cutting machines in manufacturing processes to improve efficiency and product quality. ↩ ↩ ↩ ↩ ↩

Explore this link to understand how Hot Blade Cutting can enhance your production efficiency and material handling. ↩

Learn about Cold Blade Cutting to ensure you choose the right method for your materials, preventing damage and ensuring quality. ↩