High-Speed Hook & Loop Circle Cutter for Garment Manufacturing?

In garment factories, time is tight and precision matters. Especially when cutting hook-and-loop circles for shoes, jackets, kidswear, and uniforms.

A high-speed hook & loop circle cutter automates dot production for garments, improving consistency, efficiency, and comfort—perfect for high-volume textile applications.

If you’re still cutting Velcro circles by hand or using slow tools, this guide shows how to upgrade your production with speed and style.

Why do garments need circular hook-and-loop fasteners?

From baby bibs to military uniforms, round Velcro dots offer safe, low-profile closures that won’t snag or scratch.

Circular hook-and-loop closures are preferred in apparel because they are soft, stylish, and easily integrated into fabrics without damaging the material.

Common garment uses

Clothing designers and factories use Velcro dots in:

- Children’s clothing and shoes

- Workwear and industrial uniforms

- Sportswear and athletic gear

- Fashion accessories and closures

Here’s why round dots matter:

- No sharp corners to irritate the skin

- Low profile = smoother fabric feel

- Easier for children or seniors to use

Many of our garment clients use Suzhou Haoxinhe Electrical Equipment Co., Ltd. tools like the round shape cutting machine and different shapes cutting machine to supply circular Velcro closures in thousands of garment types.

How does a high-speed circle cutter improve garment production?

Manual circle cutting is slow and inaccurate. It leads to uneven edges, fabric damage, and inconsistent sizes that affect product quality.

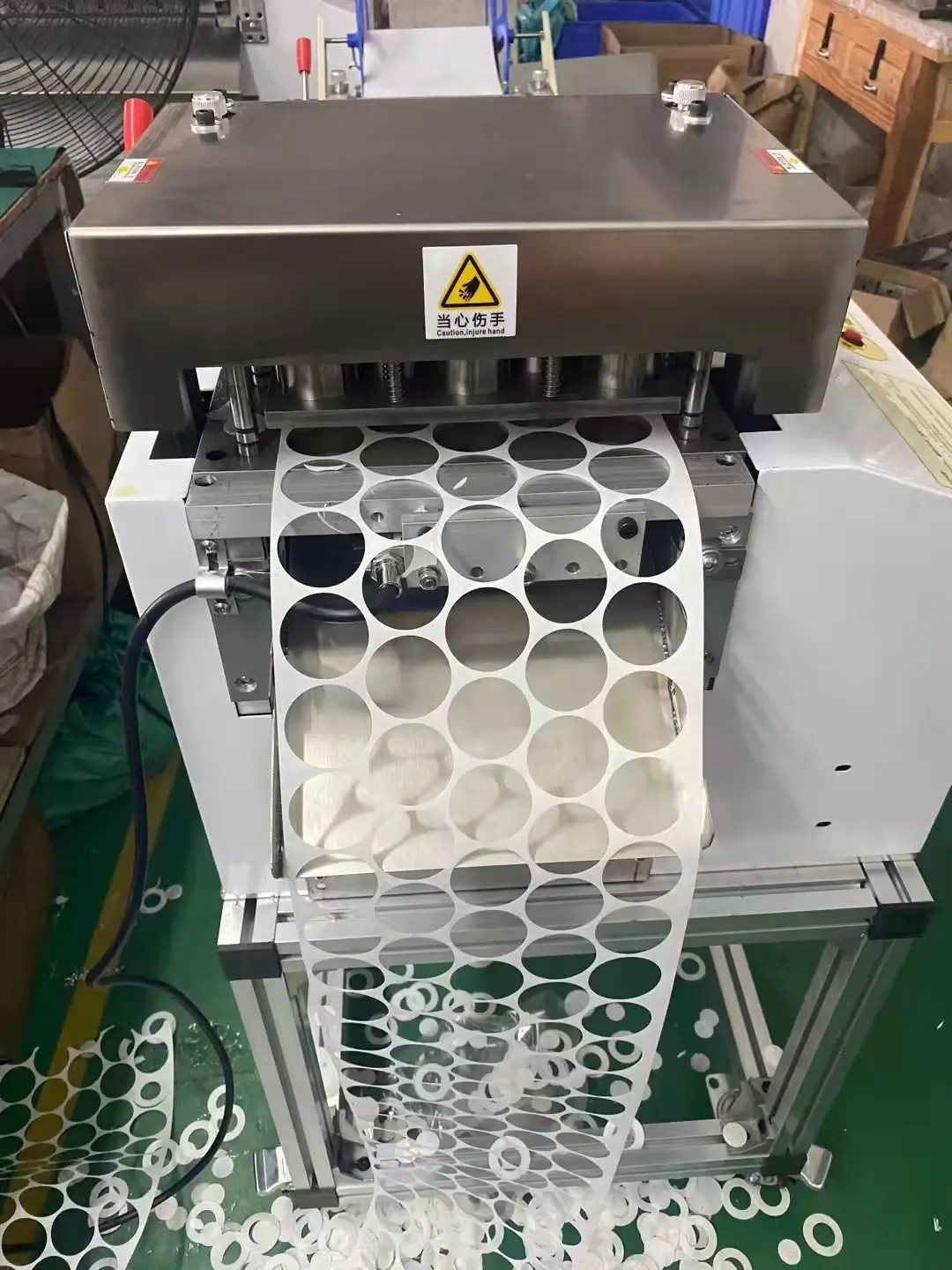

A high-speed hook & loop circle cutter processes large rolls of material into perfect dots—automatically, cleanly, and fast.

Designed for fabric compatibility

Our hot and cold cutting machine or rotary bevel cutting machine delivers:

- Up to 10,000 dots per hour

- Diameter options from 10mm to 80mm

- Clean, sealed edges to prevent fraying

- Compatibility with soft-loop, nylon, and polyester Velcro

Manual vs. High-Speed Comparison:

| Feature | Manual Cutting | High-Speed Circle Cutter |

|---|---|---|

| Speed | ~300–500 dots/hour | 5,000–10,000 dots/hour |

| Edge Quality | Jagged or uneven | Smooth, sealed |

| Labor Requirement | 2–3 workers | 1 operator |

| Consistency | Low | High |

| Fabric Damage Risk | Moderate | Minimal |

A client in Italy manufacturing adaptive garments for the elderly saw a 70% reduction in labor costs after switching to our automatic punching cutting machine, which replaced 3 manual stations.

What types of hook-and-loop material can be processed for apparel?

Garment-grade Velcro differs from industrial types. It’s softer, thinner, and more skin-friendly, requiring specific handling during cutting.

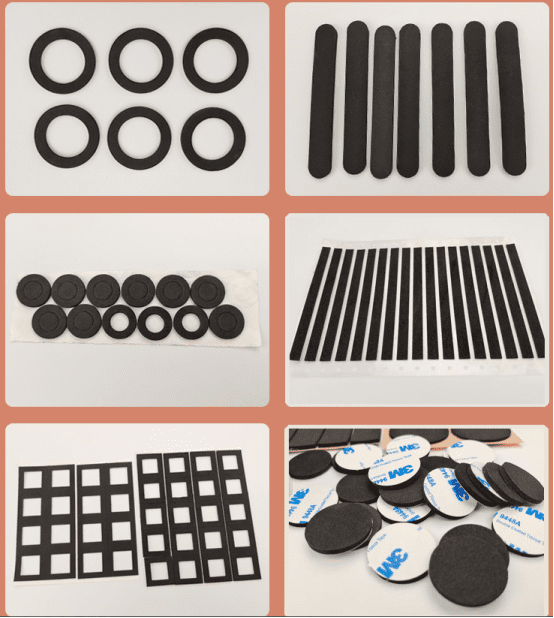

Our machines support a wide range of hook-and-loop materials used in clothing—backed or unbacked, adhesive or sew-on, soft-loop or micro-hook.

Supported materials

Whether you need Velcro for a baby bib or a fire-retardant uniform, our machines—like the protective foam cutting machine—can handle it:

- Sew-on loop tape

- Adhesive-backed circles

- Fire-retardant Velcro (EN469/EN533 compliant)

- Stretchable Velcro (for sports or medical wear)

Material Application Table:

| Material Type | Garment Use | Compatible Machine Model |

|---|---|---|

| Soft sew-on loop (white) | Children’s shirts, babywear | Round shape cutting machine |

| Hook tape (black, adhesive) | Uniform closures, jackets | Hot and cold cutting machine |

| Fire-retardant Velcro | Safety suits, firefighter gear | Rotary bevel cutting machine |

| Micro hook | Underwear, performance wear | Different shapes cutting machine |

We’ve helped a French textile OEM create color-coded Velcro dots for school uniforms using our webbing ribbon cutting machine, streamlining their batch labeling system.

How does this machine support garment line integration?

Clothing lines run fast, and every second counts. Your Velcro dot cutter must keep up and fit into your sewing or assembly station.

Haoxinhe cutters are line-ready, programmable, and compact—built to integrate with modern textile workflows and reduce bottlenecks.

Integration features

Key features include:

- Touchscreen controls with preset sizes

- Adjustable feeding speeds

- Auto-sensor for roll-end detection

- Built-in counter to manage batch output

Some garment factories integrate our cutter right next to their sewing station, so workers can grab pre-cut dots in real time.

Integration Benefits Table:

| Feature | Benefit for Garment Factory |

|---|---|

| Compact size | Fits into tight production zones |

| Auto roll-feeding | Reduces manual intervention |

| Adjustable speeds | Matches to sewing line rhythm |

| Data export support | Links to production tracking software |

We’ve supported clients in Germany, Singapore, and Canada who needed ISO-compliant, CE-certified machines with documentation for safety and textile certification audits.

Can this machine handle customized Velcro for branded garments?

Fashion and uniform clients often want more than basic circles—they need brand-printed Velcro or unique shapes to stand out.

Our circle cutters can be upgraded with custom dies and logo embossing tools—making them ideal for brand-conscious garment lines.

Branding & customization features

With rotary bevel and different shapes cutting machines, we offer:

- Custom-shaped Velcro (stars, tabs, hearts)

- Color-coded dots by size or function

- Heat-transfer-compatible Velcro circles

- Embossed or printed brand marks

Branding Customization Chart:

| Feature | Brand Benefit | Machine Add-On Required |

|---|---|---|

| Custom shapes | Unique garment identity | Die kit for different shapes cutter |

| Logo embossing | Visible brand elements | Embossing tool attachment |

| Color batch separation | Easier SKU and size identification | Roll-change system |

| UV-print-ready Velcro | Fashion label applications | UV-prep feeder for cutting machine |

One Canadian designer created detachable patches using our circle cutters and color-coded Velcro dots—making their kidswear both fun and functional.

Conclusion

A high-speed hook & loop circle cutter transforms garment manufacturing—reducing labor, improving quality, and enabling custom fasteners at scale.

Insights

High-speed hook & loop circle cutters are essential in garment manufacturing, enabling fast, consistent, and skin-friendly Velcro dot production. They support fabric compatibility, automation, and brand customization—making them ideal for modern textile factories.