Furniture Industry Boost with Round Adhesive Velcro Cutting Machines?

Furniture needs to be smart, modular, and easy to install — but messy fastening solutions ruin the customer experience.

Our round adhesive Velcro cutting machine helps furniture brands create clean, consistent, and strong hook & loop attachments for cushions, panels, covers, and accessories.

Let’s look at how this machine helps manufacturers cut better Velcro dots, speed up production, and elevate product quality across the furniture industry.

Why is Velcro so common in furniture design?

Velcro isn’t just for temporary fixes — in furniture, it’s a strategic tool.

Hook & loop dots offer a quiet, adjustable, non – invasive fastening option used in modular sofas, acoustic panels, removable cushions, storage furniture, and more.

Where It’s Used

| Furniture Component | Velcro Application |

|---|---|

| Seat Cushions | Anti – slip bottom dots |

| Backrests | Removable support padding |

| Sofa Covers | Easy – to – remove fabric sections |

| Wall Panels | Repositionable acoustic tiles |

| Storage Lids | Flap closures without hinges |

Velcro dots work invisibly while allowing end users to replace, remove, or reconfigure their furniture — but only when they’re precisely cut and properly aligned.

What does the round adhesive Velcro cutter do?

If you’re manually cutting Velcro dots, you’re wasting time and material — and risking sloppy finishes.

Our machine automatically cuts adhesive – backed Velcro tape into perfect round dots at industrial speed — up to 10,000 dots per hour.

Key Features

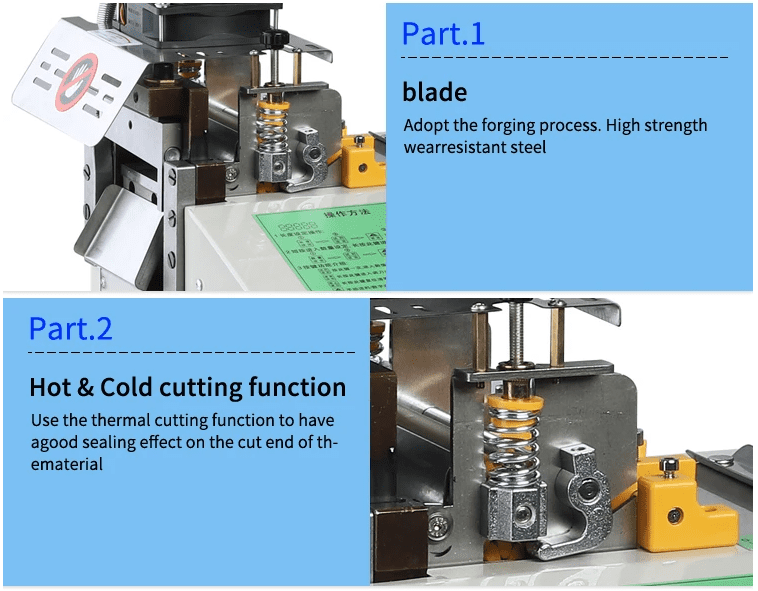

- Rotary Die Cutting System

Cuts uniform dots at high speed with minimal vibration - Cold Cutting Mode

Protects adhesive layers from heat damage - Auto Feeding and Waste Removal

Hands – free operation from start to finish - Interchangeable Dies

Easily switch between 10mm to 30mm+ sizes - Adhesive Support System

Prevents glue residue buildup or stretching

No scissors, no hand punches, and no adhesive distortion — just clean dots ready to stick and stay.

How does it improve furniture production efficiency?

Furniture manufacturing involves mass repetition and short delivery timelines — Velcro dot cutting shouldn’t be the bottleneck.

Our machine replaces multiple manual steps with a single, streamlined system that delivers clean – cut Velcro dots ready for use or packaging.

Efficiency Boost Breakdown

| Metric | Manual Cutting | Haoxinhe Dot Cutter |

|---|---|---|

| Output/hr | 500–800 pcs | 10,000+ pcs |

| Dot Accuracy | ±2mm | ±0.2mm |

| Labor Need | 2–3 workers | 1 operator |

| Dot Waste | High | <3% |

| Adhesive Integrity | Often compromised | Cold – cut safe |

Case Study: Modular Furniture Maker (Italy)

- Used to hand – cut dots for seat cushion kits

- Dot sizes varied, glue distorted under scissors

- Switched to Haoxinhe dot cutting machine:

- Production time dropped by 70%

- Dot consistency improved drastically

- Reduced customer complaints about slipping cushions

This kind of upgrade doesn’t just speed up assembly — it improves the product experience for end users.

What sizes and materials does it support?

Furniture uses more than just 20mm dots — you need flexibility for different applications.

Our machine supports multiple dot diameters, custom shapes, and all standard adhesive Velcro types.

Dot Sizes

| Diameter | Use Case |

|---|---|

| 10mm | Decorative flaps or small covers |

| 15mm | Wall – mounted tiles |

| 20mm | Chair cushions |

| 25mm | Sofa backrests |

| 30mm+ | Acoustic panels and large covers |

Material Compatibility

| Material | Supported? | Notes |

|---|---|---|

| Adhesive – Backed Hook | ✅ | Cold cut mode recommended |

| Nylon Loop Tape | ✅ | Rugged, reusable |

| Colored Velcro | ✅ | For branding or design integration |

| Flame – Retardant Velcro | ✅ | For commercial furniture applications |

| Recycled/Eco – Friendly Velcro | ✅ | Sustainable packaging available |

Whether you’re creating furniture for home, office, or public spaces — this machine handles the fastening dots that make your design practical and modular.

Why choose Suzhou Haoxinhe for Velcro cutting?

You need a supplier that understands scale, speed, and real production pressure.

Suzhou Haoxinhe Electrical Equipment Co., Ltd. is a certified Velcro cutting machine manufacturer with 5 production lines, CE certification, and global clients in furniture, packaging, apparel, and electronics.

What We Offer

- Custom Die Design

Logos, unique shapes, branded patches - Fast Shipping (7–15 Days Worldwide)

Europe, North America, Southeast Asia, and more - Multilingual Support

English, French, Chinese - Remote Setup and After – Sales Training

Installation videos and live support - Sustainability Options

Energy – efficient models, recycled Velcro compatibility

We also manufacture:

- Webbing ribbon cutters

- Hot and cold Velcro cutters

- Foam, label, and edge banding machines

- All – in – one cut – and – rewind systems

Whether you’re making sofas, wall panels, or soft furnishings, our Velcro dot cutter fits into your production line — and helps scale it.

Conclusion

Furniture brands looking to streamline and scale Velcro dot use can rely on our round adhesive Velcro cutting machine — for speed, accuracy, and a cleaner final product.

Insights

Furniture makers can improve modular product assembly with Suzhou Haoxinhe’s adhesive Velcro dot cutting machine. With 10,000+ cuts/hour, ±0.2mm accuracy, and cold – cut support for sticky – backed Velcro, it ensures cleaner application and faster production. Perfect for cushions, covers, panels, and smart furniture.