Applications of Polypropylene Rope Cutting Machines

Applications of Polypropylene Rope Cutting Machines Struggling to meet production deadlines because cutting ropes manually takes too long? You’re likely missing out on the power of automation. Polypropylene rope cutting machines1 are used across various industries that demand precision, speed, and consistency in processing rope-based materials. When you know who’s using these machines and why, […]

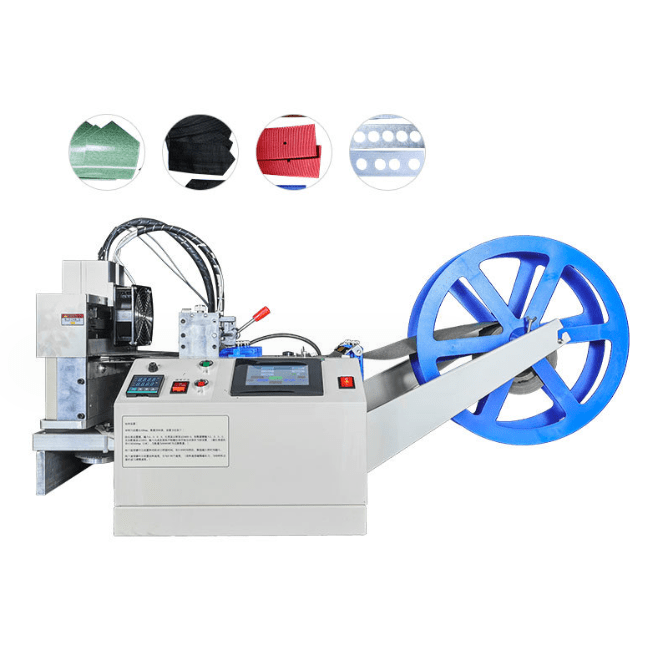

Polypropylene Rope Cutting Machine Overview

Polypropylene Rope Cutting Machine Overview If you’re struggling to cut polypropylene ropes efficiently and accurately, you’re not alone. Many industrial buyers face similar issues due to poor-quality machines or outdated manual processes. A polypropylene rope cutting machine1 is designed to automate and precision-cut PP ropes into specified lengths, saving time, reducing waste, and improving output […]

What determines the lifespan of dog collar punching machine dies?

What determines the lifespan of dog collar punching machine dies1? A worn-out die can wreck precision, slow production, and increase waste—especially when you’re punching thousands of holes per day. The lifespan of punching dies depends on material hardness, machine calibration2, maintenance3, and how often you change materials during production. 1: The lifespan of dog collar […]

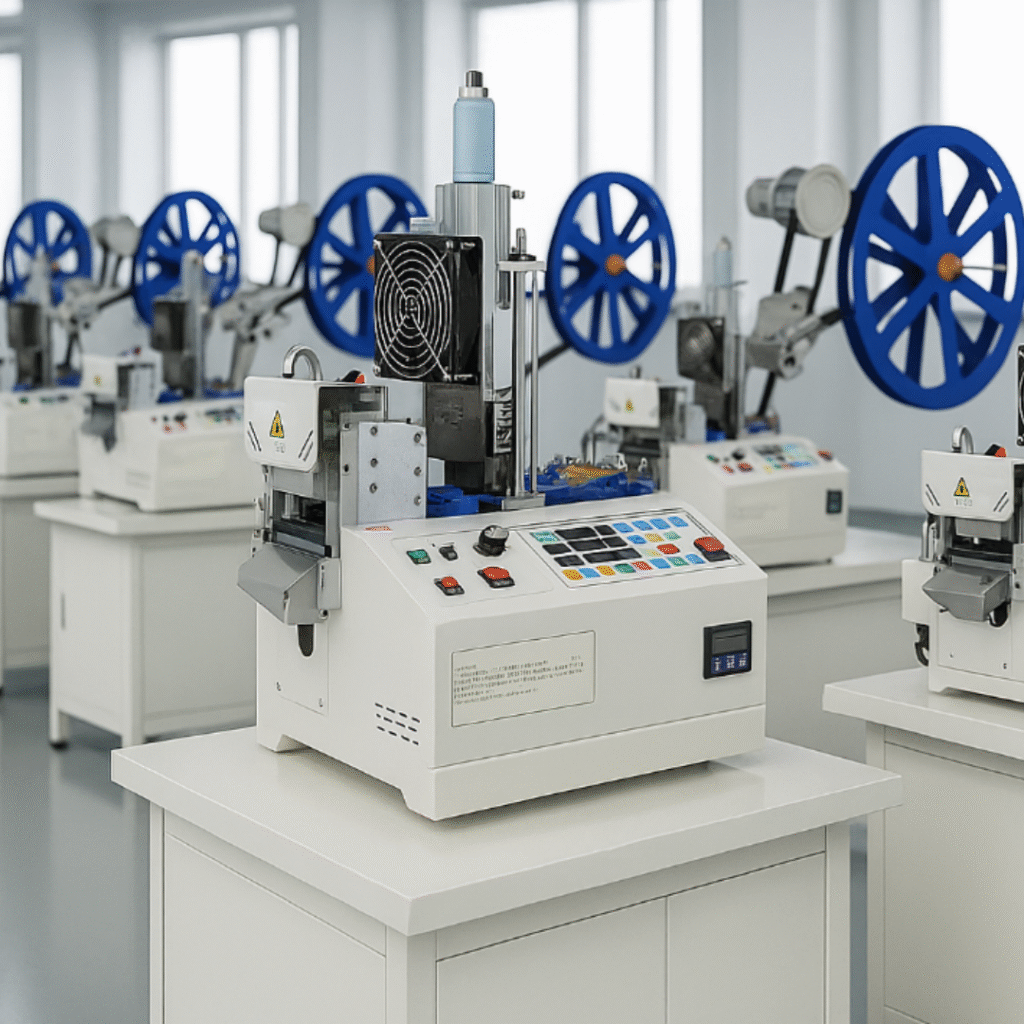

Where Can You Buy a High-Quality Webbing Punch Hole Machine?

Where Can You Buy a High-Quality Webbing Punch Hole Machine? Buying from the wrong source leads to delays, safety issues, or machines that don’t perform. High-quality webbing punch hole machines are best sourced directly from trusted manufacturers like Suzhou Haoxinhe Electrical Equipment Co., Ltd., through B2B platforms or factory-direct channels. High-quality webbing punch hole machines […]

How to choose between manual and automatic dog collar punching machines?

How to choose between manual and automatic dog collar punching machines? Choosing the wrong type of punching machine can lead to slow delivery times, low profits, and frustrated customers. If you’re producing over 200 collars per hour, automatic punching machines1 are more cost-effective than manual ones, despite higher upfront costs. 1: Selecting between manual and […]

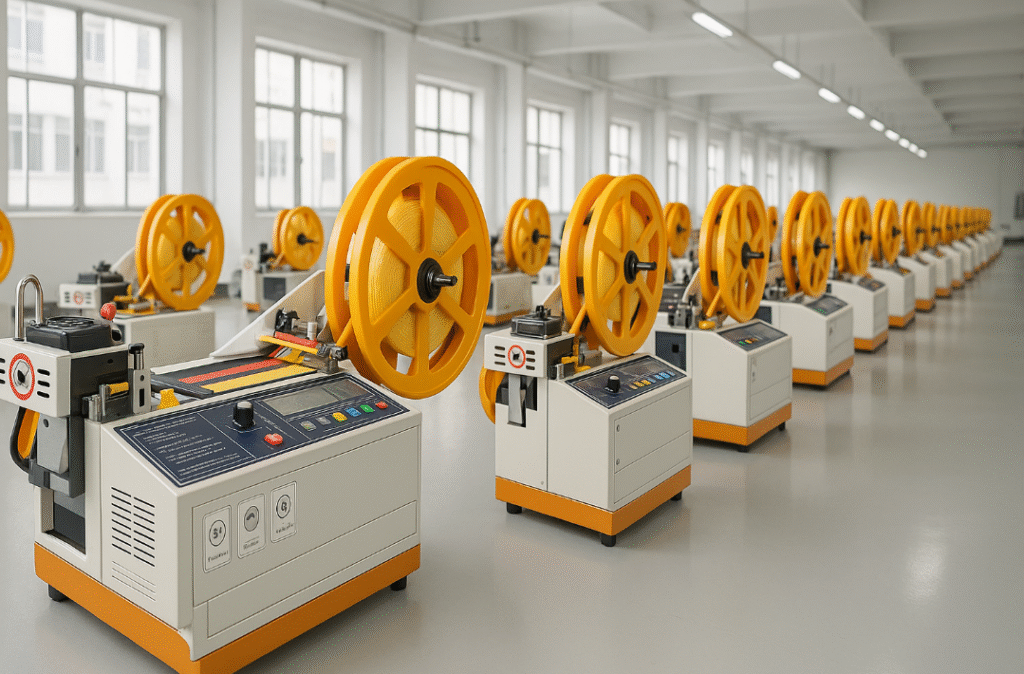

What Are the Top Brands for Webbing Punch Hole Machines?

What are the top brands for webbing punch hole machines? With so many manufacturers claiming "industrial-grade" performance, it’s hard to know who to trust. Top webbing punch hole machine brands1 include Suzhou Haoxinhe2, JOMAR, Cutex, and LIHIT. Each offers different strengths depending on your production needs. 1: Suzhou Haoxinhe2‘s automatic webbing punching machines3 stand out […]

How to optimize workflow between cutting and punching phases?

How to optimize workflow between cutting and punching phases? If the punching and cutting steps don’t match speed or rhythm, you lose time, materials, and money. To optimize workflow between cutting and punching, synchronize your machines1, streamline data flow2, and use automation tools such as timing relays3 and smart sensors4. 1: Streamlining the transition from […]

Which bubble wrap cutting machine type is better for thick film?

Which bubble wrap cutting machine type is better for thick film? Cutting thick bubble wrap film often causes headaches: jagged edges, split seams, or costly downtime when machines can’t keep up. For bubble wrap films above 100 microns, hot-knife cutters give superior sealed edges, while rotary blades are cheaper to maintain but less effective on […]

Can a Webbing Punch Hole Machine Also Cut and Seal Edges?

Can a Webbing Punch Hole Machine Also Cut and Seal Edges? Many manufacturers wonder if their punch hole machine can handle multiple operations to save equipment costs. Standard webbing punch hole machines1 cannot simultaneously cut and seal edges—they’re designed specifically for hole creation. However, specialized combination machines like ultrasonic models can perform all three functions […]

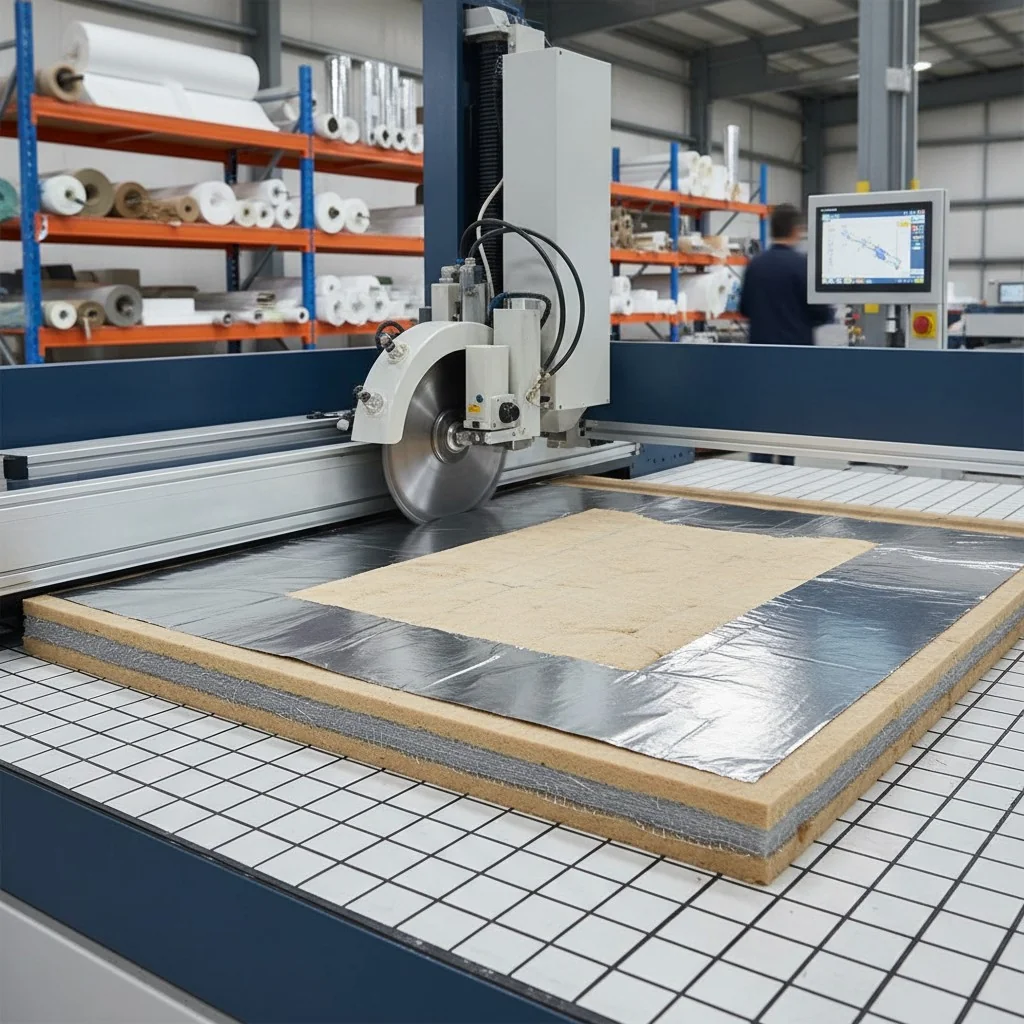

Which PVC sheet cutter best tackles multi-layer industrial insulation sheets?

Which PVC sheet cutter best tackles multi-layer industrial insulation sheets? Multi-layer insulation sheets made from PVC or composite materials are tough to cut cleanly—standard blades jam, warp, or burn through them. The best PVC sheet cutters1 for multi-layer insulation are rotary bevel cutting machines2 and automatic punching cutters3 with programmable depth control4 and reinforced blade […]

How to set up a bubble wrap cutting machine for e-commerce peaks?

How to set up a bubble wrap cutting machine for e-commerce peaks? During sales peaks like Black Friday or Christmas, delays in packaging cost money. If your bubble wrap cutter can’t keep up, fulfillment bottlenecks hit fast. To handle 1,000–3,000 parcels/day efficiently, set up your bubble wrap cutting system with the right speed, conveyor flow, […]

Can a bubble wrap cutting machine process other materials?

Can a bubble wrap cutting machine process other materials? Many buyers assume a bubble wrap cutter is a one-trick pony. But with the right settings and blade, you might get more than you paid for. Yes, most bubble wrap cutting machines1 can handle similar soft materials like PE foam2, PET film3, and kraft paper4—if the […]