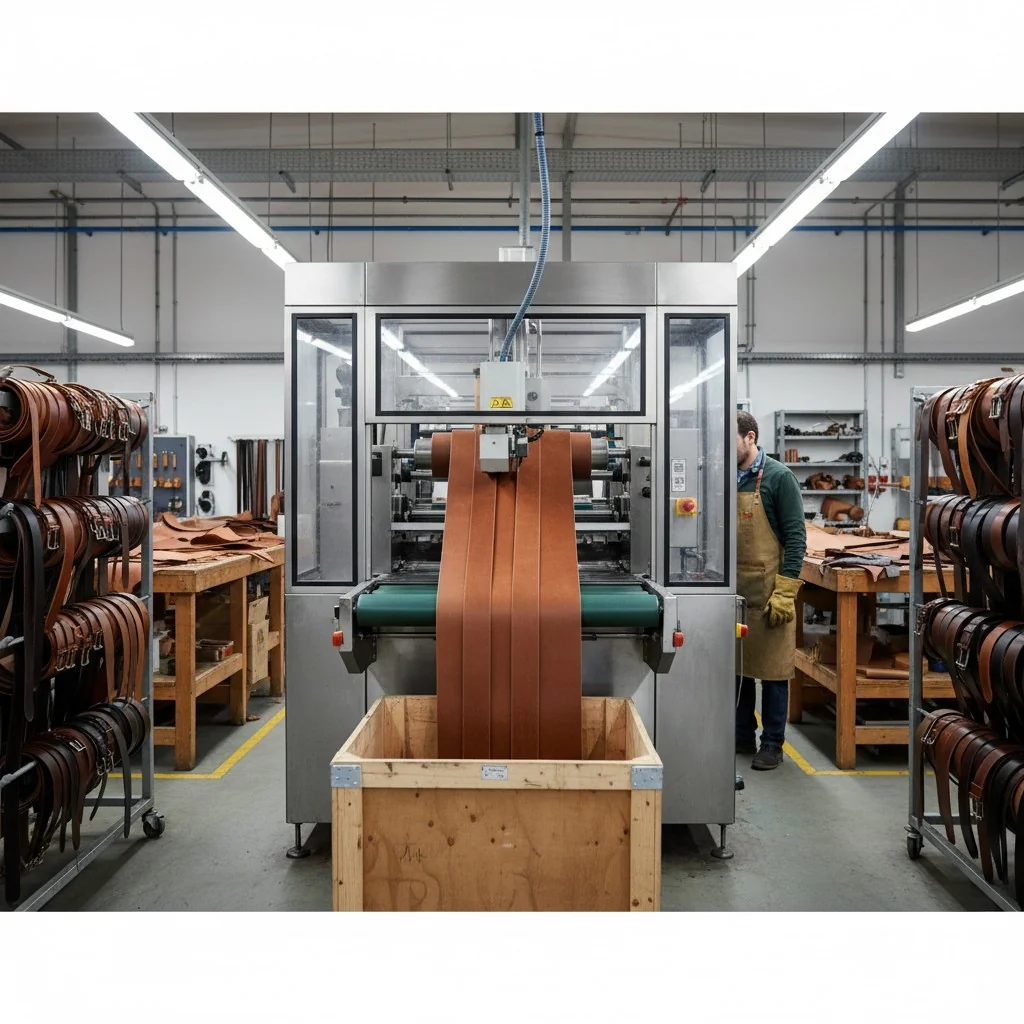

Can automated cutters reduce labor time for belt leather fabrication?

Can automated cutters reduce labor time for belt leather fabrication? Leather belt manufacturers often lose production hours to slow hand-cutting and poor edge consistency that result in high defect rates. Yes—automated cutters significantly reduce labor time in leather belt fabrication by delivering fast, precise cuts at scale, with reduced waste and minimal manual handling. 1: […]

Can an auto ribbon cutter reduce waste in luxury gift packaging?

Can an auto ribbon cutter reduce waste in luxury gift packaging? Inconsistent ribbon lengths and frayed ends are common problems in luxury packaging—leading to material waste and poor presentation. Yes—an automatic ribbon cutter reduces waste by delivering consistent lengths, sealing edges cleanly, and eliminating manual errors in premium gift wrapping lines. An auto ribbon cutter […]

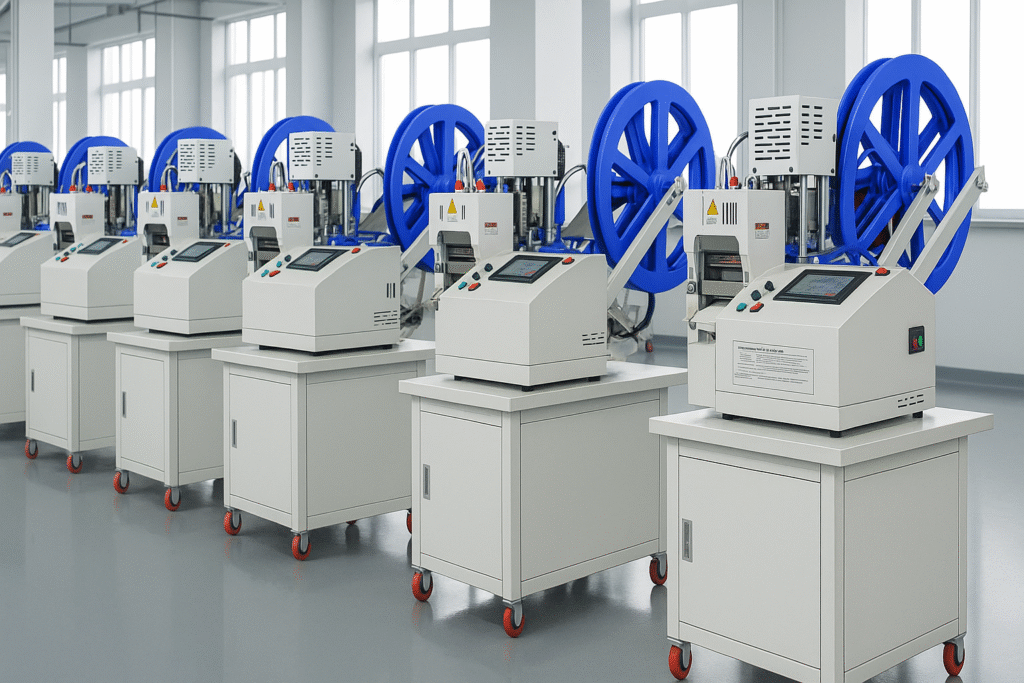

How Does a Webbing Punch Hole Machine Work?

How Does a Webbing Punch Hole Machine Work? If you don’t understand how it works, you can’t choose the right machine for your factory. A webbing punch hole machine works by feeding webbing material into a die set, then applying force with a punch head to cut clean holes at precise positions. A punch and […]

How to Maintain a Webbing Punch Hole Machine for Long-Term Use?

How to Maintain a Webbing Punch Hole Machine for Long-Term Use? A neglected machine will cost you more in downtime than the price of regular care. Maintain a webbing punch hole machine1 by lubricating moving parts, inspecting dies, cleaning daily, and scheduling preventive maintenance every 3–6 months. Regular maintenance is key to extending the lifespan […]

Which brands of bubble wrap cutting machines are reliable for continuous duty?

Which brands of bubble wrap cutting machines are reliable for continuous duty? Factories running high-output packaging lines face a tough problem: some machines fail after a few months, forcing downtime and costly repairs. Reliable bubble wrap cutting machine brands for continuous duty are those offering strong build quality, fast service, and quick spare part delivery—especially […]

How to choose a bubble wrap cutting machine for factory use?

How to choose a bubble wrap cutting machine for factory use? Many factories struggle to scale because their cutting process is slow, inconsistent, or wastes material. This kills productivity and profitability. For a factory handling bubble wrap, choosing the right cutting machine depends on order volume, labor availability, and the level of automation required to […]

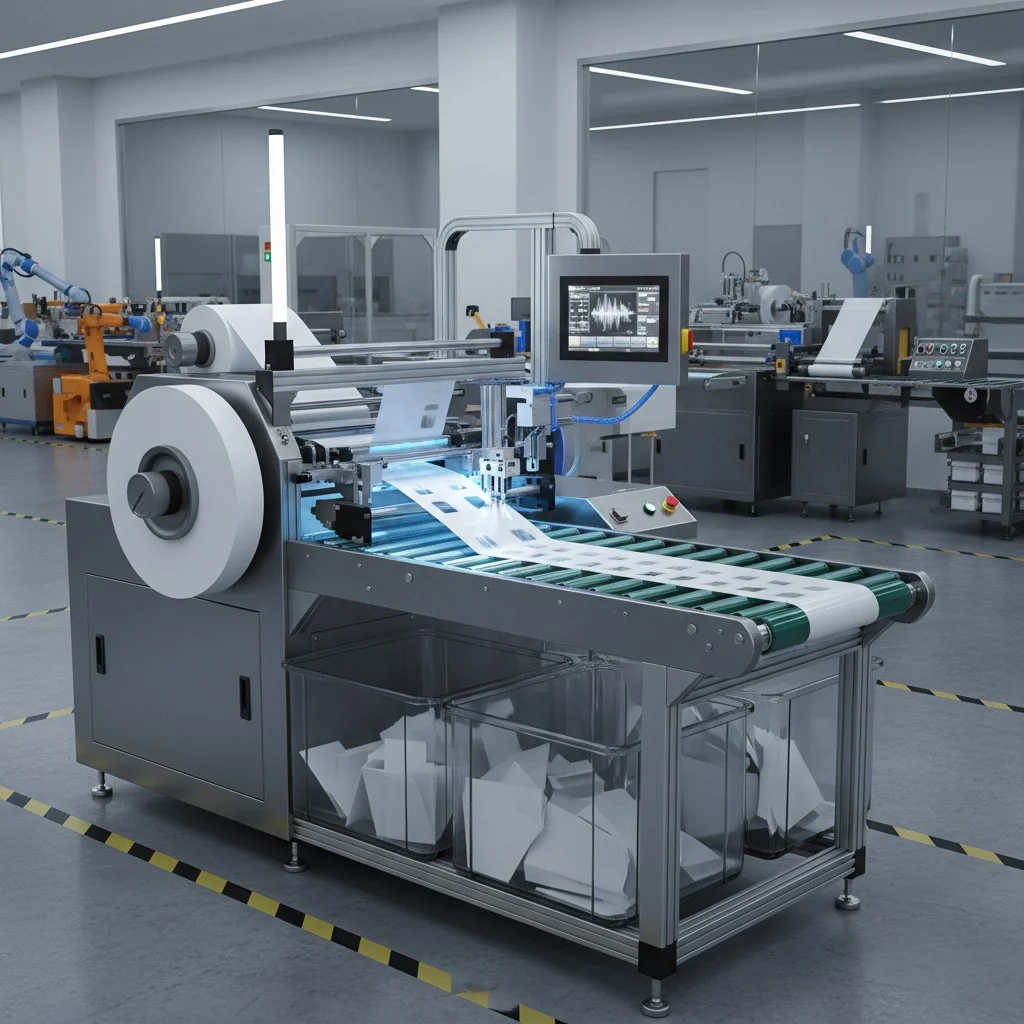

Why Are Digital Label Cutting Machines Booming in Industrial Packaging?

Why Are Digital Label Cutting Machines Booming in Industrial Packaging? The demand for faster, smarter, and more precise label production has exploded. Industrial packaging can’t keep up without automation. Digital label cutting machines1 are booming because they offer faster turnaround, precision, and adaptability that traditional die-cutting cannot match in today’s high-mix, low-volume production. 1: Digital […]

What’s the Ideal Leather Strap Cutting Machine for Handmade vs Industrial Operations?

What’s the Ideal Leather Strap Cutting Machine for Handmade vs Industrial Operations? Choosing the right leather strap cutting machine1 can make or break your production. Whether you’re crafting bespoke accessories or running an industrial operation, the wrong tool means wasted time and material. The ideal machine depends on your scale: manual or semi-automatic for handmade […]

Cutting Flexible Strips: Challenges and Machine Selection

Cutting Flexible Strips: Challenges and Machine Selection Cutting narrow strips of flexible material seems simple until you try it. The material moves, stretches, or frays – ruining your productivity. The main challenges in flexible strip cutting are material movement, edge quality, and consistency. Choosing between rotary and linear cutting machines depends on your material type, […]

How Strip Cutter Machines Streamline Textile Production: Laser vs Blade Cutters

How Strip Cutter Machines Streamline Textile Production: Laser vs Blade Cutters Manual cutting methods waste hours of labor and cause inconsistent textile strips. Modern strip cutter machines transform textile production by creating hundreds of identical strips per hour with perfect edges – eliminating fraying and material waste. While both laser and blade cutters improve efficiency, […]

What Industries Benefit Most from Electric Rope Cutting Machines?

What Industries Benefit Most from Electric Rope Cutting Machines? Frayed rope ends cost marine and construction companies thousands in wasted materials annually. Electric rope cutters1 serve marine, construction, logistics, and emergency services best by delivering sealed cuts that won’t unravel under stress – critical for safety-critical applications. These heavy-duty sectors share three common needs: absolute […]

How Does a Belt Cutting Machine Improve Throughput?

How Does a Belt Cutting Machine Improve Throughput in Conveyor Belt Production? Manual belt cutting creates bottlenecks in production lines and inconsistent results. Automated belt cutting machines1 boost throughput2 by combining continuous conveyor feeding with laser-guided precision cutting, achieving speeds up to 3x faster than manual methods while maintaining ±0.5mm accuracy. These systems process materials […]