Which automation features increase ROI in aluminium foil cutting machines?

Which automation features increase ROI in aluminium foil cutting machines? Manual cutting is slow, inconsistent, and expensive over time—even with skilled labor. Automation features like servo motor control, touch screen interfaces, auto-tension systems, and smart sensors significantly improve speed, reduce waste, and increase ROI in aluminium foil cutting. If you’re investing in cutting machines, think […]

What are the most common technical issues with aluminium foil cutting machines and how to solve them?

What are the most common technical issues with aluminium foil cutting machines and how to solve them? Frequent breakdowns, foil jams, and uneven cuts can destroy your production schedule—and your reputation. The most common issues with aluminium foil cutting machines include blade dullness, tension misalignment, sensor failure, and overheating. Each has a simple solution if […]

How to choose the right aluminium foil cutting machine for food-grade manufacturing?

How to choose the right aluminium foil cutting machine for food-grade manufacturing? Using the wrong cutting machine for food packaging can lead to contamination, poor hygiene, and failed inspections. To choose the right aluminium foil cutting machine for food-grade manufacturing, you must prioritize hygienic design, clean-cut accuracy, material compatibility, and compliance with global food safety […]

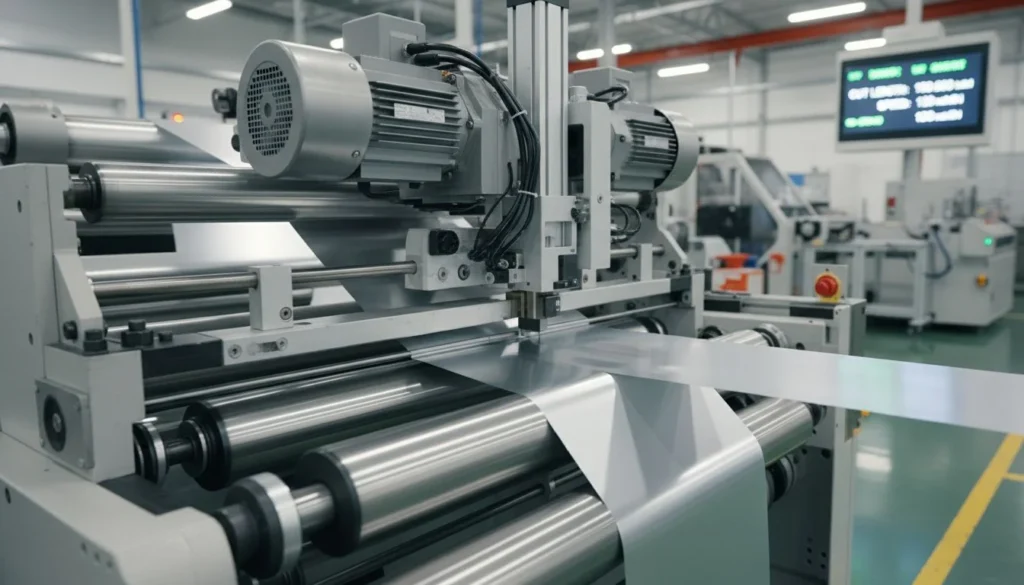

What is the best aluminium foil cutting machine for high-speed industrial packaging lines?

What is the best aluminium foil cutting machine1 for high-speed industrial packaging lines? Struggling with slow, inaccurate foil cuts that disrupt your packaging line? The best aluminium foil cutting machine for industrial packaging combines high-speed precision2 cutting, stable automation, and robust material handling—guaranteeing zero downtime in continuous operations. If your business handles thousands of metres […]

Can a bubble wrap cutting machine integrate into an automatic packing line?

Can a bubble wrap cutting machine integrate into an automatic packing line? Manually feeding bubble wrap into packing lines is inefficient and error-prone—especially when your orders scale up and time becomes critical. Yes, a bubble wrap cutting machine can be seamlessly integrated into an automatic packing line through PLC/IO connections, encoder output, and conveyor synchronization—especially […]

Can a bubble wrap cutting machine handle different film thicknesses?

Can a bubble wrap cutting machine handle different film thicknesses? Many factories struggle when film thickness changes. A machine set for thin bubble wrap may jam, overheat, or leave rough edges on thicker films. Yes, modern bubble wrap cutting machines1 can handle different thicknesses, but operators must adjust roller pressure, hot-knife temperature, and cutting speed. […]

Which Bubble Wrap Cutting Machine Is Best? Full Comparison of 10 Popular Models

Which Bubble Wrap Cutting Machine Is Best? Full Comparison of 10 Popular Models Not sure which bubble wrap cutting machine1 to invest in? This 2026 comparison guide evaluates the 10 most popular models across cost, speed, material compatibility, and reliability to help you choose the best. Whether you’re sourcing for a packaging factory, fulfillment center, […]

Where to Buy Bubble Cutting Machines with Fast US Shipping?

Where to Buy Bubble Cutting Machines with Fast US Shipping? If your orders are delayed because you’re waiting weeks for a cutting machine, your business could be losing customers and money. You can buy bubble cutting machines with fast US shipping from verified suppliers on Alibaba, US-based warehouses, or directly from manufacturers like Suzhou Haoxinhe […]

Best Bubble Cutting Machines for Small Packaging Businesses?

Best Bubble Cutting Machines for Small Packaging Businesses? If you’re struggling with messy manual cutting or inconsistent results, you’re not alone. Poor packaging efficiency could be silently killing your profits. The best bubble cutting machines for small packaging businesses offer precision, speed, and minimal waste—ideal for companies aiming to optimize their packaging lines without breaking […]

How to Choose the Right Leather Strap Cutting Machine for Your Workshop?

How to Choose the Right Leather Strap Cutting Machine for Your Workshop? Wasting expensive leather materials due to poor cutting quality? Choosing the wrong machine can cost thousands in rejected products and wasted materials. The right leather strap cutting machine depends on your production volume, leather thickness, and required precision – with key features like […]

Top 10 Chinese Manufacturers of Bubble Wrap Cutting Machines (Factory Direct Options)

Top 10 Chinese Manufacturers of Bubble Wrap Cutting Machines (Factory Direct Options) Tired of middlemen and overpriced machines with questionable support? This 2026 list introduces 10 trusted Chinese manufacturers of bubble wrap cutting machines that offer factory-direct prices, international shipping, and export-ready support. If you’re sourcing from China for resale or direct use, these are […]

How to operate a bubble wrap cutting machine safely?

How to operate a bubble wrap1 cutting machine safely? Bubble wrap cutting machines can be dangerous if safety standards are ignored. Poor training or missing safeguards can lead to serious injuries. Safe operation requires compliance with CE or UL standards, use of emergency stops, proper guarding, interlocks, and consistent PPE use. Safe Operation Starts with […]