What determines the lifespan of dog collar punching machine dies?

What determines the lifespan of dog collar punching machine dies1? A worn-out die can wreck precision, slow production, and increase waste—especially when you’re punching thousands of holes per day. The lifespan of punching dies depends on material hardness, machine calibration2, maintenance3, and how often you change materials during production. 1: The lifespan of dog collar […]

Where Can You Buy a High-Quality Webbing Punch Hole Machine?

Where Can You Buy a High-Quality Webbing Punch Hole Machine? Buying from the wrong source leads to delays, safety issues, or machines that don’t perform. High-quality webbing punch hole machines are best sourced directly from trusted manufacturers like Suzhou Haoxinhe Electrical Equipment Co., Ltd., through B2B platforms or factory-direct channels. High-quality webbing punch hole machines […]

How to Choose the Right Leather Strap Cutting Machine for Your Workshop?

How to Choose the Right Leather Strap Cutting Machine for Your Workshop? Wasting expensive leather materials due to poor cutting quality? Choosing the wrong machine can cost thousands in rejected products and wasted materials. The right leather strap cutting machine depends on your production volume, leather thickness, and required precision – with key features like […]

How to choose between manual and automatic dog collar punching machines?

How to choose between manual and automatic dog collar punching machines? Choosing the wrong type of punching machine can lead to slow delivery times, low profits, and frustrated customers. If you’re producing over 200 collars per hour, automatic punching machines1 are more cost-effective than manual ones, despite higher upfront costs. 1: Selecting between manual and […]

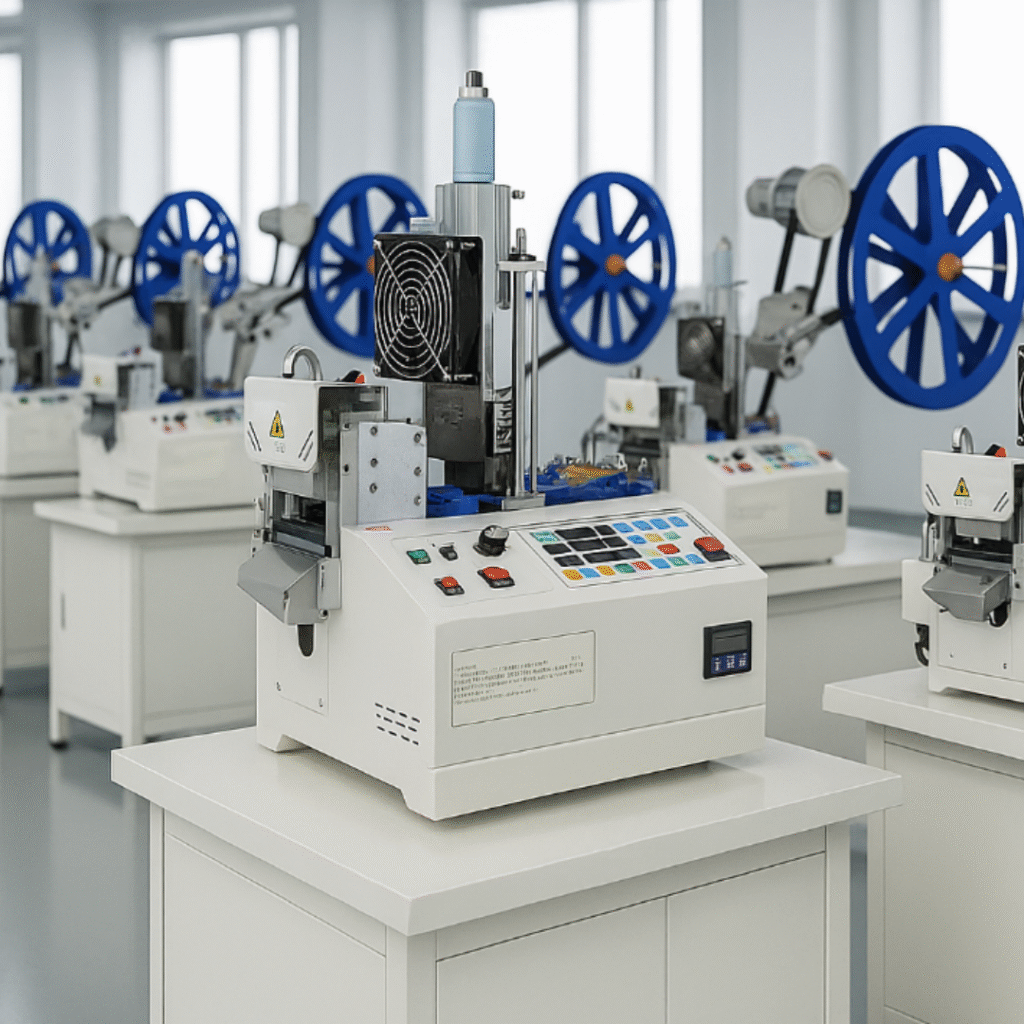

What Are the Top Brands for Webbing Punch Hole Machines?

What are the top brands for webbing punch hole machines? With so many manufacturers claiming "industrial-grade" performance, it’s hard to know who to trust. Top webbing punch hole machine brands1 include Suzhou Haoxinhe2, JOMAR, Cutex, and LIHIT. Each offers different strengths depending on your production needs. 1: Suzhou Haoxinhe2‘s automatic webbing punching machines3 stand out […]

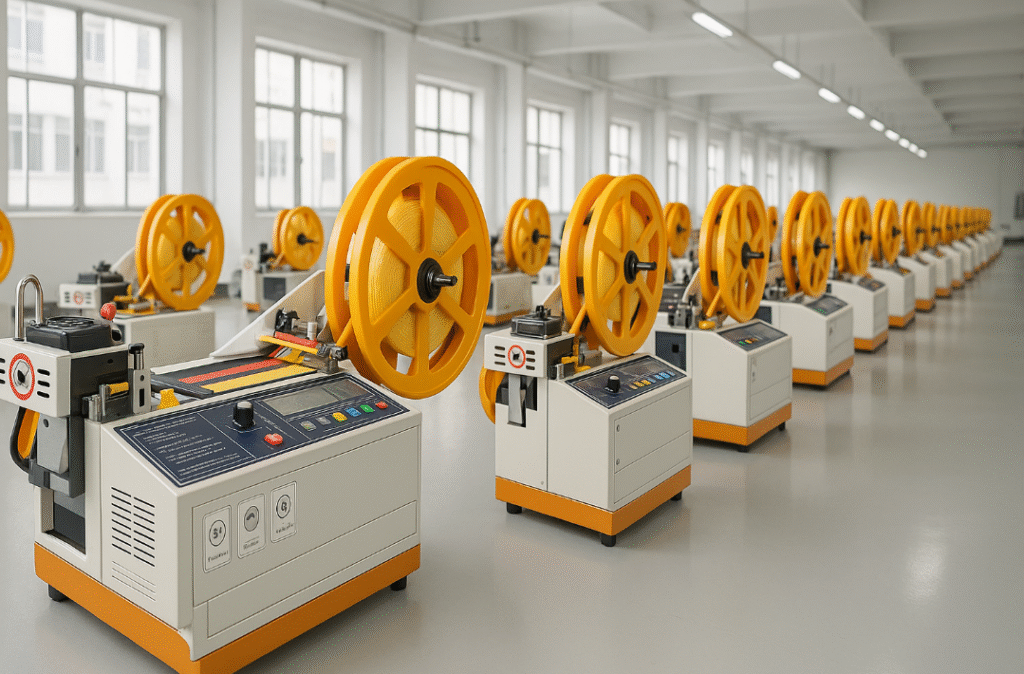

10 Industrial Bubble Wrap Cutting Machines You Should Consider in 2026

10 Industrial Bubble Wrap Cutting Machines You Should Consider in 2026 Looking for heavy-duty cutting machines that match your growing industrial packaging demand? These 10 industrial bubble wrap cutting machines1 are built for high-volume, continuous-use environments, offering powerful features and consistent performance in 2026. Whether you run a packaging, logistics, or manufacturing facility, these machines […]

How to optimize workflow between cutting and punching phases?

How to optimize workflow between cutting and punching phases? If the punching and cutting steps don’t match speed or rhythm, you lose time, materials, and money. To optimize workflow between cutting and punching, synchronize your machines1, streamline data flow2, and use automation tools such as timing relays3 and smart sensors4. 1: Streamlining the transition from […]

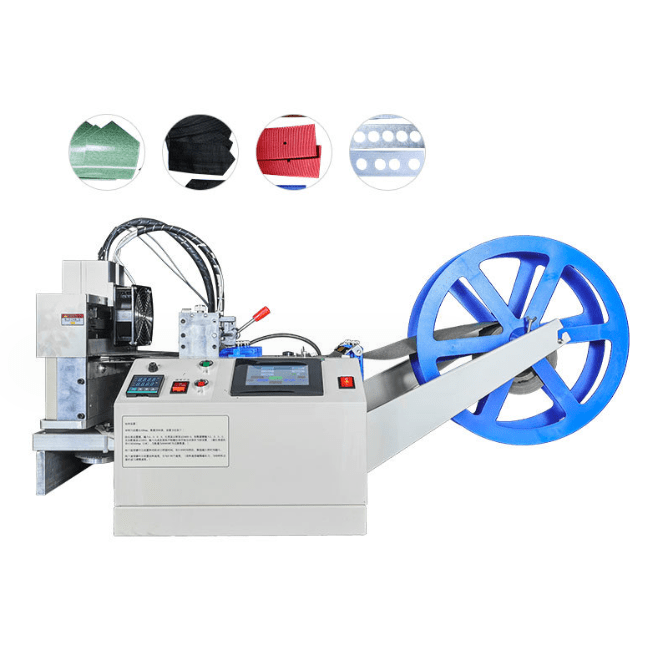

Can a Webbing Punch Hole Machine Also Cut and Seal Edges?

Can a Webbing Punch Hole Machine Also Cut and Seal Edges? Many manufacturers wonder if their punch hole machine can handle multiple operations to save equipment costs. Standard webbing punch hole machines1 cannot simultaneously cut and seal edges—they’re designed specifically for hole creation. However, specialized combination machines like ultrasonic models can perform all three functions […]

Why is roll-to-sheet cutting the future in flexible packaging lines?

Why is roll-to-sheet cutting the future in flexible packaging lines? Flexible packaging lines suffer from jammed web tension, imprecise cuts, and inconsistent panel lengths—especially when scaling high-speed runs. Roll-to-sheet cutting1 ensures higher throughput, cleaner edges, and format flexibility2, making it the go-to solution for modern flexible packaging3 production. 1: Roll-to-sheet cutting1 is revolutionizing flexible packaging […]

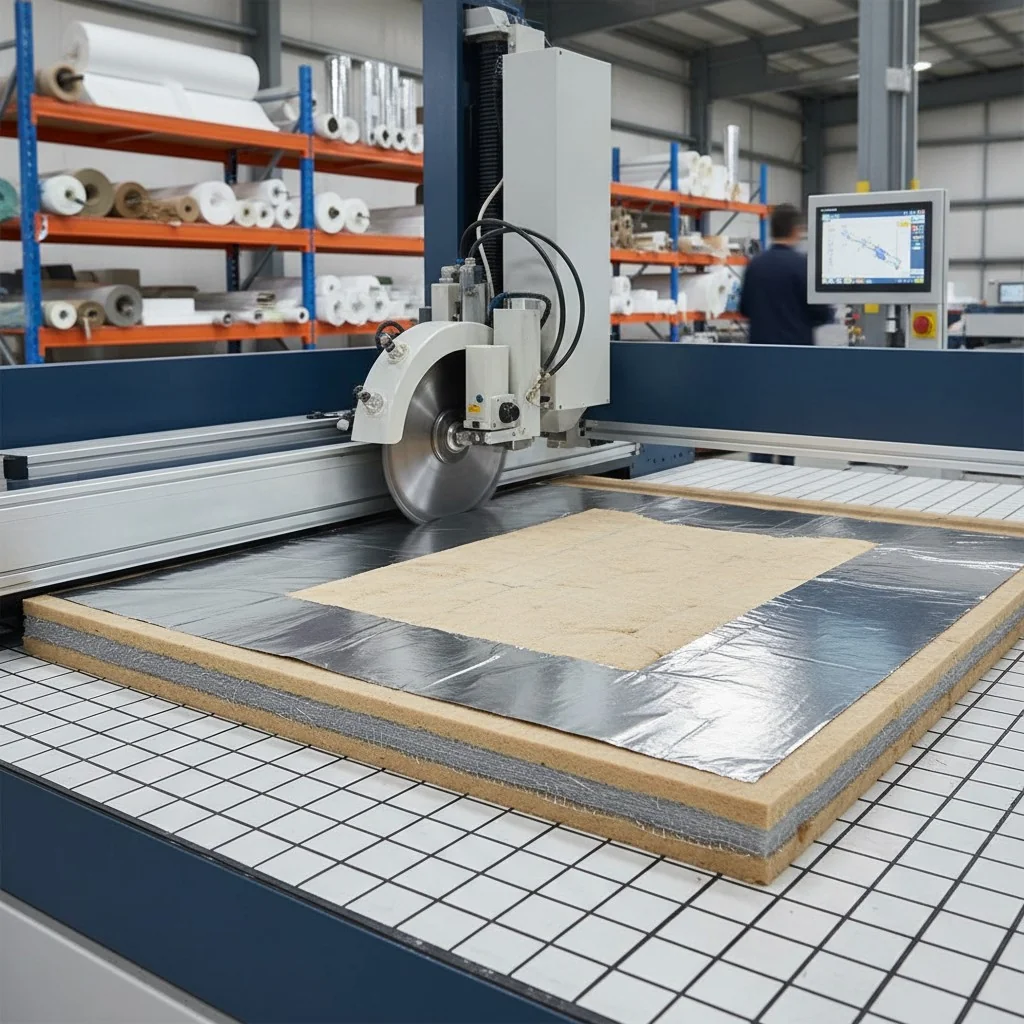

Which PVC sheet cutter best tackles multi-layer industrial insulation sheets?

Which PVC sheet cutter best tackles multi-layer industrial insulation sheets? Multi-layer insulation sheets made from PVC or composite materials are tough to cut cleanly—standard blades jam, warp, or burn through them. The best PVC sheet cutters1 for multi-layer insulation are rotary bevel cutting machines2 and automatic punching cutters3 with programmable depth control4 and reinforced blade […]

Can a bubble wrap cutting machine process other materials?

Can a bubble wrap cutting machine process other materials? Many buyers assume a bubble wrap cutter is a one-trick pony. But with the right settings and blade, you might get more than you paid for. Yes, most bubble wrap cutting machines1 can handle similar soft materials like PE foam2, PET film3, and kraft paper4—if the […]

How to fix length inaccuracy drifting over a shift?

How to fix length inaccuracy drifting over a shift? It’s frustrating: your bubble wrap cutter starts the day perfectly calibrated, but by the afternoon, your cuts are 2–3 cm off. This drift causes rework, waste, and customer complaints. To fix length inaccuracy over long shifts, focus on three areas: encoder calibration, roller wear, and temperature […]