How Automatic Ribbon Cutting Machines Solve Key Production Problems?

How Automatic Ribbon Cutting Machines Solve Key Production Problems? Manufacturers wasting hours on manual ribbon cutting face mounting production delays and material waste. Automatic ribbon cutting machines solve four major production problems: inconsistent lengths, slow output, material waste, and labor fatigue. Programmable cutting length enhances textile workflow by enabling quick changeovers, precise repeatability, and batch-specific […]

Why Is a Roll to Sheet Cutting Machine Essential in Label and Film Manufacturing?

Why Is a Roll to Sheet Cutting Machine Essential in Label and Film Manufacturing? Manual conversion from rolls to sheets creates material waste and inconsistent sizing in label production. Roll-to-sheet cutting machines1 are essential because they automate high-precision conversion of continuous rolls into ready-to-use sheets, achieving ±0.2mm dimensional accuracy while processing up to 1,200 sheets/hour […]

How does a precision belt cutter improve conveyor durability?

How does a precision belt cutter1 improve conveyor durability? Conveyor belts fail faster when they’re cut unevenly or stressed during fabrication—bad edges create weak points that wear and tear faster in use. A precision belt cutter1 improves conveyor durability by ensuring clean, even edges, consistent tension distribution, and accurate alignment across multi-layer materials2. If you […]

What Innovations Are Improving Accuracy in PVC Sheet Cutting Machines?

What Innovations Are Improving Accuracy in PVC Sheet Cutting Machines? Traditional PVC cutting methods often struggle with material deformation and inconsistent cuts. Recent innovations like laser-guided positioning1, AI-powered vision systems2, and dynamic pressure control3 are revolutionizing PVC sheet cutting accuracy. These technologies achieve precision within 0.1mm while compensating for material variations. How to Select a […]

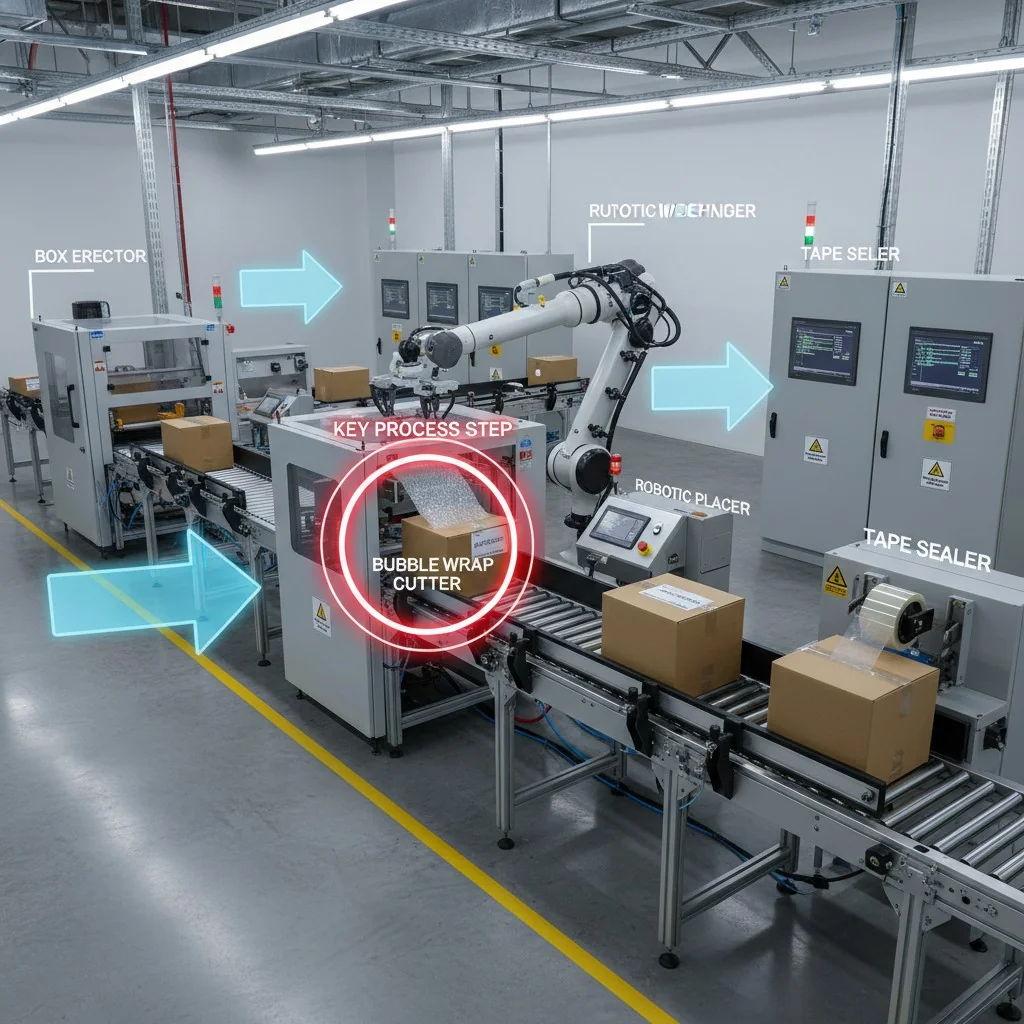

Can a bubble wrap cutting machine integrate into an automatic packing line?

Can a bubble wrap cutting machine integrate into an automatic packing line? Manually feeding bubble wrap into packing lines is inefficient and error-prone—especially when your orders scale up and time becomes critical. Yes, a bubble wrap cutting machine can be seamlessly integrated into an automatic packing line through PLC/IO connections, encoder output, and conveyor synchronization—especially […]

What are the key advantages of using an automatic belt cutting machine in industrial production lines?

What are the key advantages of using an automatic belt cutting machine in industrial production lines? Manual cutting is still common in many factories — but it’s slow, inconsistent, and labor-intensive. An automatic belt cutting machine delivers speed, precision, and reliability, helping industrial production lines reduce labor costs, eliminate errors, and boost throughput. At Suzhou […]

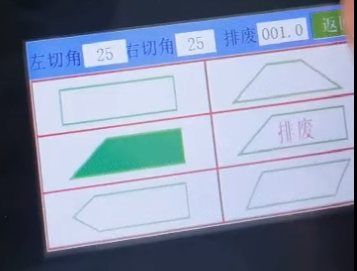

What are the most searched features in modern webbing rotary bevel cutting machines?

What are the most searched features in modern webbing rotary bevel cutting machines? tape cutter When customers shop for rotary bevel cutting machines, they’re not just looking for speed — they’re hunting for performance, durability, and automation1. The most searched features include high cutting speed, precision angle control, automation compatibility, heat sealing options, and support […]

How to choose a webbing rotary bevel cutting machine for precision cutting in automotive applications?

How to choose a webbing rotary bevel cutting machine for precision cutting in automotive applications? tape cutter Automotive manufacturers can’t afford rough cuts or measurement errors — every millimeter matters. To choose the right rotary bevel cutting machine for automotive applications, focus on cut precision, material compatibility, and production speed. Many clients in the automotive […]

Why are webbing rotary bevel cutting machines preferred in industrial strap fabrication?

Why are webbing rotary bevel cutting machines preferred in industrial strap fabrication? webbing cutter Manual cutters can’t keep up with modern industrial demands for precision, speed, and clean angled cuts. Webbing rotary bevel cutting machines are preferred in industrial strap fabrication because they deliver faster, cleaner, and more consistent cuts — essential for large-scale manufacturing. […]

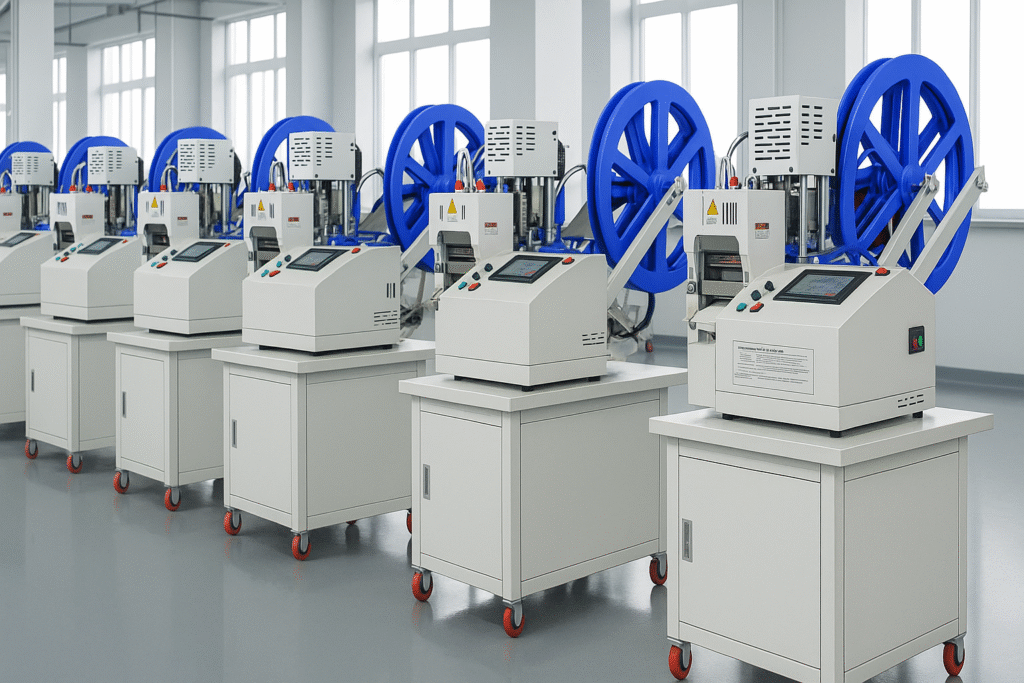

What is the most efficient webbing rotary bevel cutting machine for high-volume textile production?

What is the most efficient webbing rotary bevel cutting machine for high-volume textile production? Efficient webbing rotary bevel cutting machine in action Many textile factories struggle with low efficiency when cutting large volumes of webbing materials. The most efficient webbing rotary bevel cutting machine combines speed, precision, and automation to drastically increase throughput and reduce […]

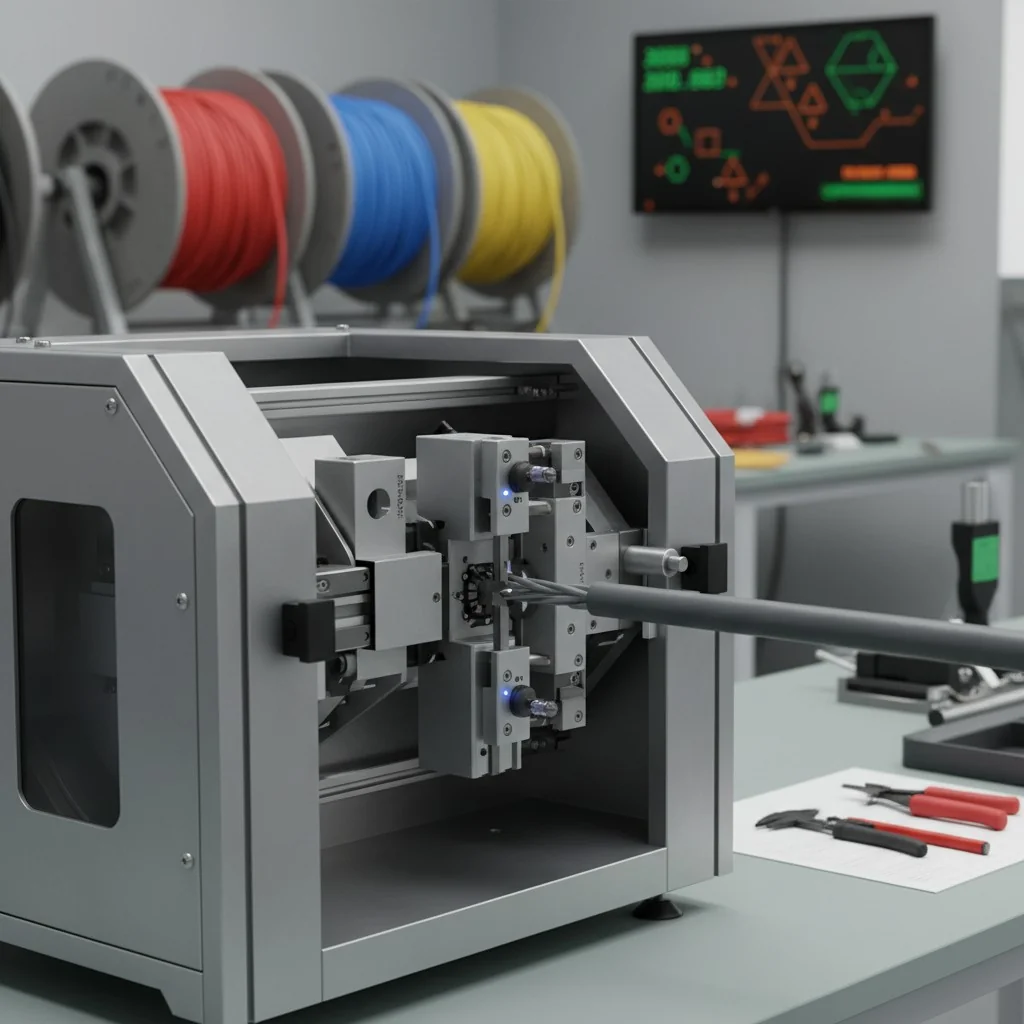

Customization Options for Rope Cutting Machines?

Customization Options for Rope Cutting Machines? custom rope cutting machine If your current rope cutting machine can’t meet your production needs, you’re not alone — many manufacturers feel stuck with one-size-fits-all solutions. Yes, rope cutting machines can be highly customized — from adjustable cutting lengths to diameter ranges and control systems. You don’t need to […]

Automatic vs. Manual PP Rope Cutting Machines

Automatic vs. Manual PP Rope Cutting Machines Still cutting polypropylene rope by hand? That might be slowing down your production and hurting your bottom line. Automatic PP rope cutting machines1 offer faster speeds, better accuracy, and long-term cost savings compared to manual cutting methods2. When you understand how these two methods compare, it’s easier to […]