Can a bubble wrap cutting machine integrate into an automatic packing line?

Manually feeding bubble wrap into packing lines is inefficient and error-prone—especially when your orders scale up and time becomes critical.

Yes, a bubble wrap cutting machine can be seamlessly integrated into an automatic packing line through PLC/IO connections, encoder output, and conveyor synchronization—especially in WMS-connected systems.

If you’re trying to automate packaging from end to end, integrating the bubble wrap cutter is one of the smartest ways to eliminate bottlenecks.

PLC/IO, encoder out, and conveyor sync options for WMS-connected lines?

You may have automated box packing and labeling. But if your bubble wrap still requires manual cutting, your automation line has a weak link.

With programmable logic controller (PLC) compatibility, encoder output, and real-time conveyor synchronization, bubble wrap cutting machines can be configured to function as an intelligent, responsive unit in your WMS-driven system.

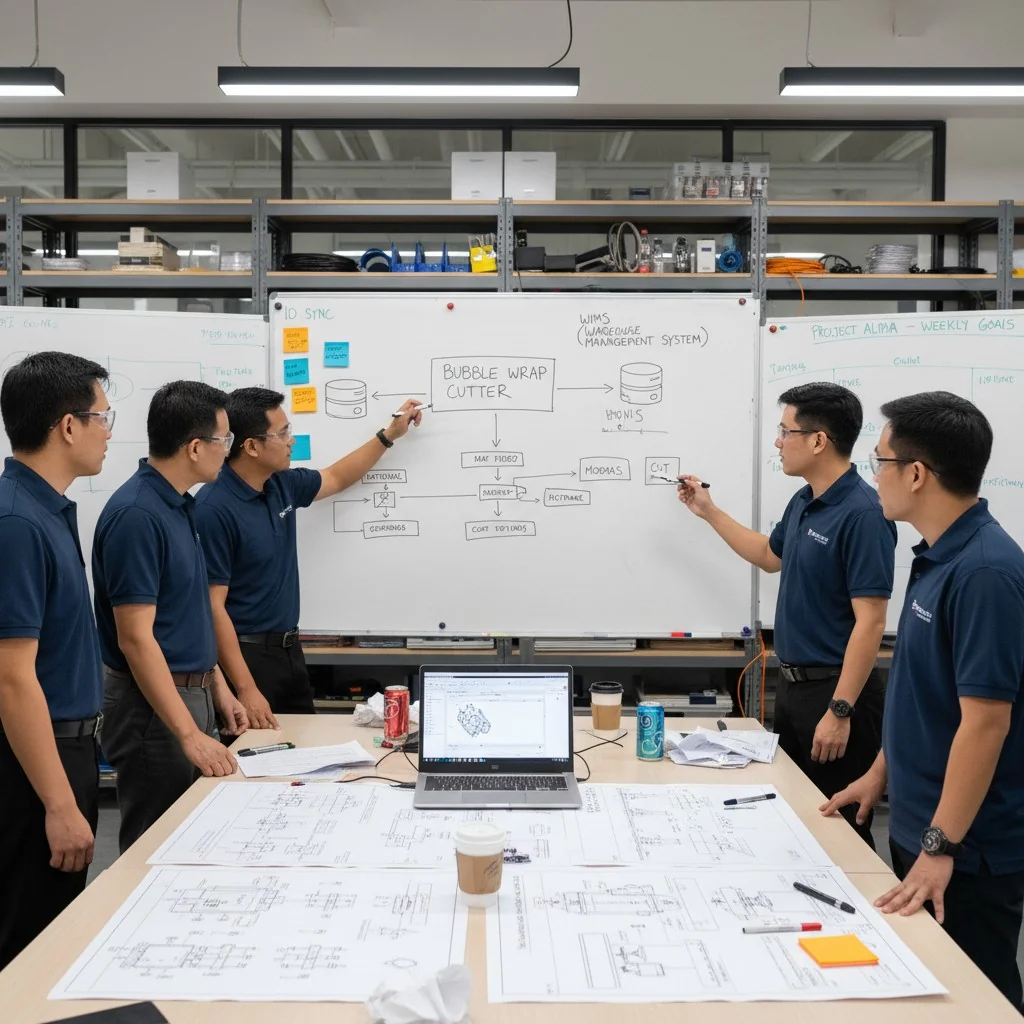

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we build machines with this level of flexibility in mind.

🧠 PLC/IO Communication: Let your WMS control the cutter

Our Bubble wrap cutting machines support both digital and analog IO to communicate with upstream and downstream equipment. This includes:

| IO Feature | Description |

|---|---|

| Digital Input | Start, stop, emergency stop |

| Digital Output | Cycle complete, error signal |

| Analog I/O (optional) | Variable cut length or feed speed |

| PLC protocols supported | Modbus RTU, RS485, optional Ethernet/IP |

| Custom integration | Dry contact relay, terminal block customization |

These allow the machine to receive commands such as:

- "Cut 350 mm of wrap now"

- "Wait until the product arrives at position X"

- "Pause if downstream machine is full"

This kind of integration helps WMS systems push dynamic data directly to the cutter based on item size, weight, or order type.

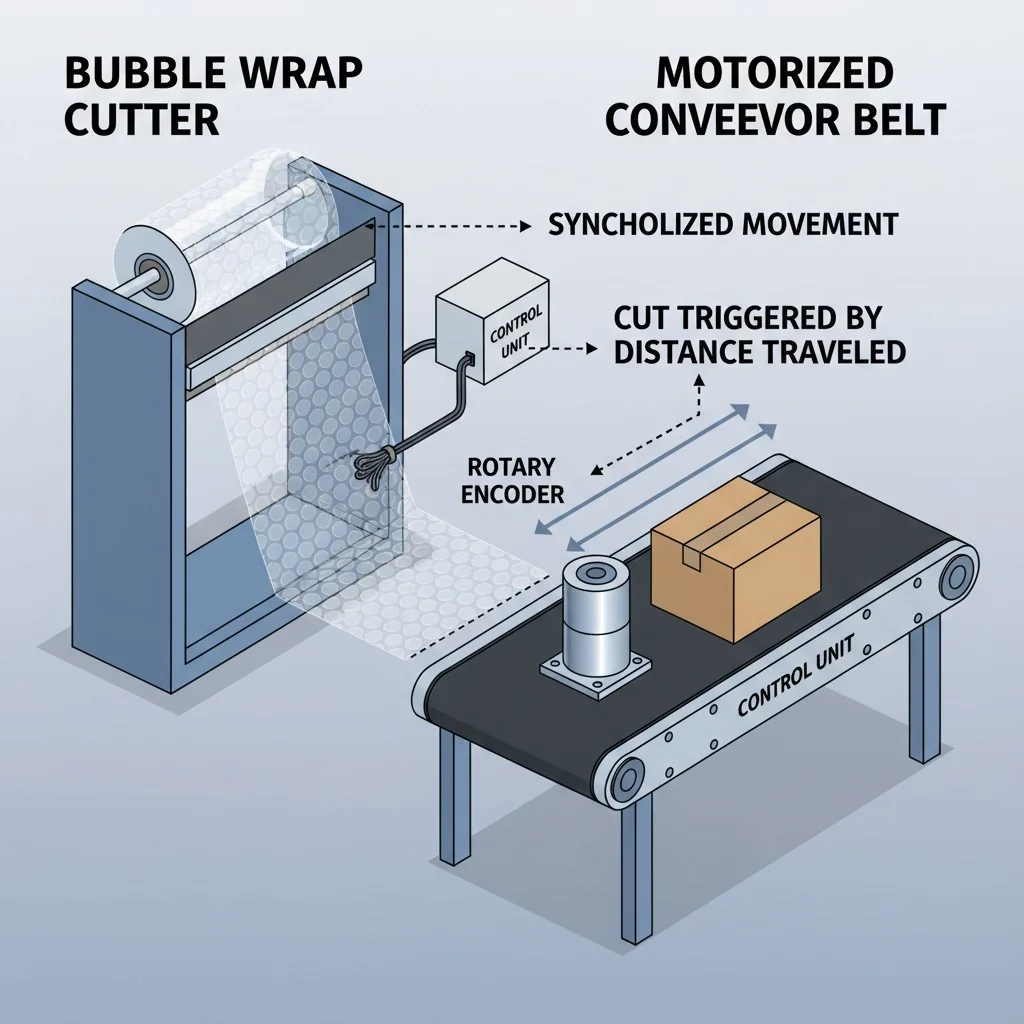

🎯 Encoder Out: Precision alignment with conveyor motion

Encoders are critical for synchronizing cutting action with the movement of your conveyor. Our machines support rotary encoder output to allow:

- Speed matching with conveyors

- Distance-based cut triggering (e.g., cut every 650 mm of belt movement)

- Real-time feedback to PLC for synchronization

This makes it possible to:

- Trigger cuts as a product passes a photoeye

- Adjust feed rate dynamically based on conveyor speed

- Prevent misalignment when conveyor speed changes

In one Canadian facility, we helped a client integrate our Protective Foam Cutting Machine with their conveyor through encoder sync. It cut exact lengths as packaging boxes moved by, without any operator input.

🔄 Conveyor Sync: Timing everything perfectly

To avoid bottlenecks or material waste, timing between machines must be perfect. We offer multiple options for synchronized conveyor operations:

| Sync Method | Description |

|---|---|

| Master/Slave Control | Cutter speed follows conveyor movement |

| Sensor Triggered Cutting | Optical/photoelectric sensors initiate cut |

| Time-Based Delay Logic | Adjustable delay after conveyor movement |

| Buffer Signal | Cutter pauses if downstream is jammed |

These systems are crucial in high-speed packaging lines. Our Webbing ribbon cutting machines and Bubble wrap cutting machines include programmable timers and logic control to handle custom sync operations.

We’ve helped multiple clients link our machines to:

- Automatic box openers

- Barcode labeling systems

- Carton sealing machines

Once integrated, the bubble wrap cutter becomes a fully responsive unit—cutting only when needed and never too early or too late.

📦 Integration with WMS and SCADA

In smart factories, WMS (Warehouse Management Systems) and SCADA systems manage more than just inventory—they orchestrate equipment behavior.

Our machines can be configured to interact with:

- WMS barcode systems

- MES job allocation platforms

- Real-time production dashboards

What this allows:

- Automated wrap length selection based on order

- Automatic job switching

- Error feedback to the control room

- Data logging of material use per order

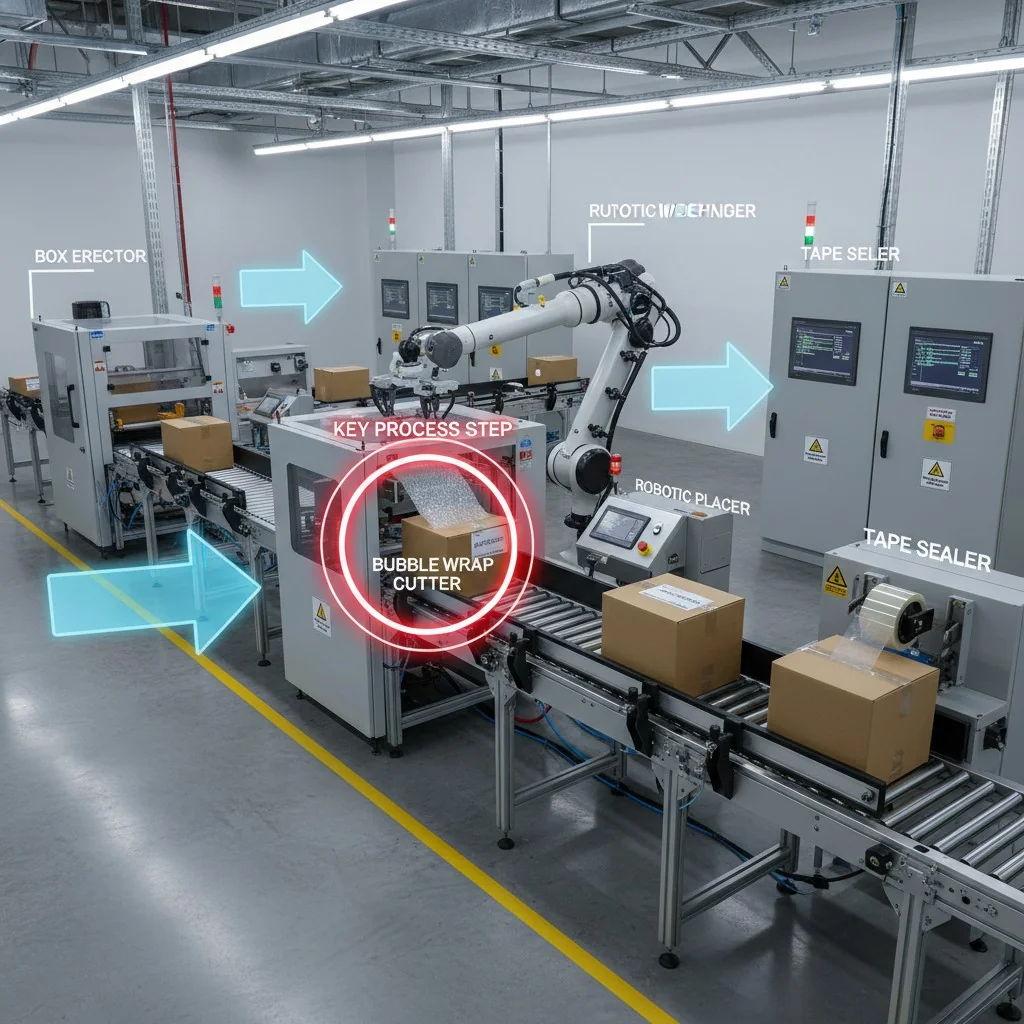

🧩 Real-World Example: End-to-End Integration

In one Germany-based facility producing electronic components, we helped connect our Bubble wrap cutting machine into a line that included:

- Box erector

- Bubble wrap cutter

- Robotic item placer

- Label printer

- Tape sealer

The cutter received signals directly from the WMS to cut different lengths based on the product SKU. This removed human error and boosted packing efficiency by 47% within two weeks.

Conclusion

An integrated bubble wrap cutter completes the automation puzzle—turning fragmented lines into smart, connected systems.

🧠 Industry Insight: Smart Integration Turns Cutters into Value Centers

In modern packaging automation, a bubble wrap cutting machine is no longer a stand-alone tool—it’s a node in your data-driven production ecosystem. But here’s the reality: most low- to mid-tier machines on the market weren’t designed with true integration in mind. They require bolt-on workarounds or don’t support clean IO communication.

HAOXINHE is different. Their systems are automation-native, meaning they offer direct IO terminals, encoder sync, and Modbus/Ethernet support straight from the factory. This isn’t just for bragging rights—it’s about uptime. One client in the EU eliminated cut timing errors that used to jam downstream carton sealers just by syncing the cutter with a conveyor encoder.

Pro tip: Don’t just ask if a cutter “has PLC control.” Ask if it supports event-based logic, like “cut after barcode scan” or “pause if box reject gate is closed.” That’s the true benchmark of integration-ready hardware.

In smart factories, even your bubble wrap cutter should think like part of the network—not a button-pushed machine.

Suzhou Haoxinhe Electrical Equipment Co., Ltd. produces Bubble wrap cutting machines, Protective Foam Cutting Machines, and Webbing ribbon cutting machines designed for full automation. With PLC/IO interfaces, encoder synchronization, and conveyor sync options, our machines integrate directly into WMS- and MES-managed environments. Whether you’re building your first smart line or upgrading an outdated setup, our factory-grade solutions are built for speed, accuracy, and total control.

Looking for an integration-ready cutting solution? Contact me at cherryhaoxinhesz@gmail.com or visit hxcuttingmachine.com.