Can a bubble wrap cutting machine handle different film thicknesses?

Many factories struggle when film thickness changes. A machine set for thin bubble wrap may jam, overheat, or leave rough edges on thicker films.

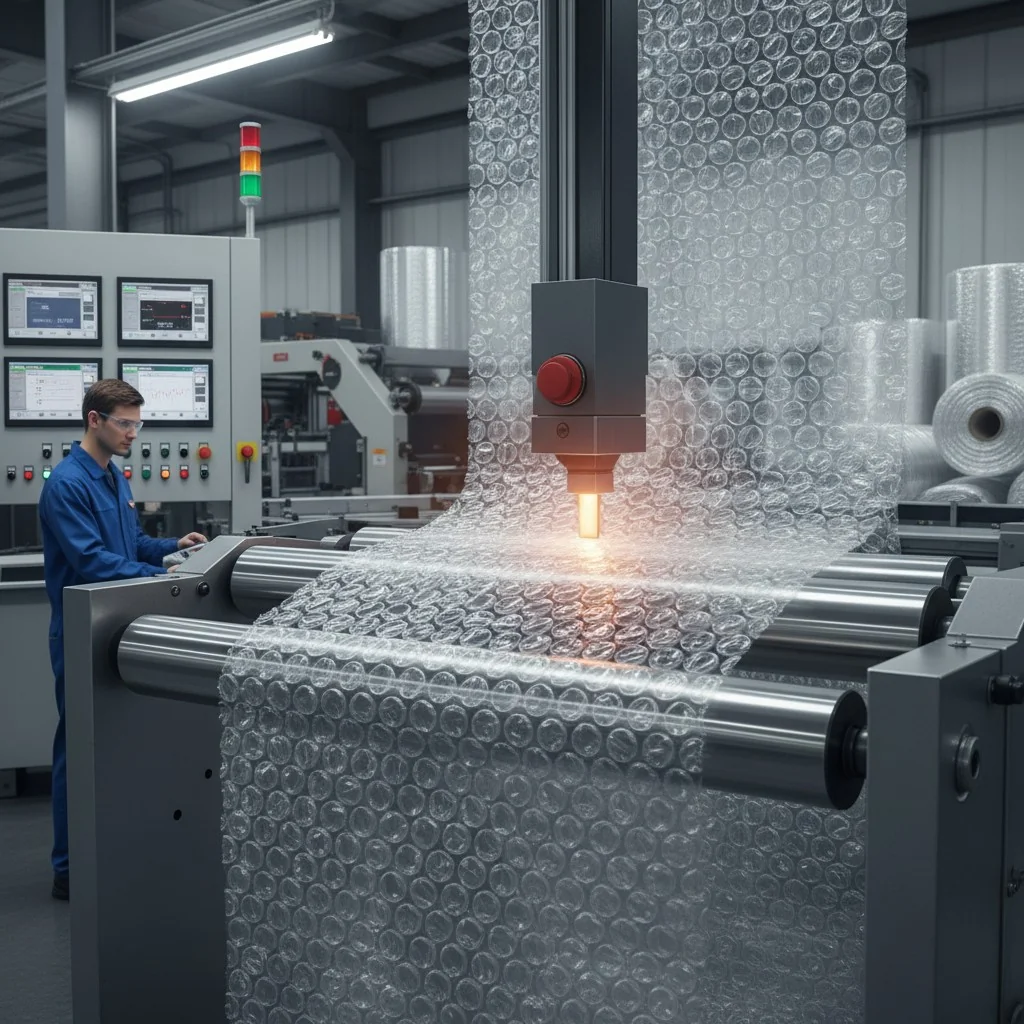

Yes, modern bubble wrap cutting machines1 can handle different thicknesses, but operators must adjust roller pressure, hot-knife temperature, and cutting speed.

- Versatile Cutting Capability: Modern bubble wrap cutting machines1 are built to handle a wide range of film thicknesses.

- Adjustable Settings: Machines offer flexible configurations2 to suit various packaging materials and production needs.

- Thickness Range: Many models support 0.1mm to 3mm3 or more, ideal for both light and heavy-duty applications.

- Manufacturer Specs Matter: Always check the specified thickness range before purchasing to ensure compatibility.

- Efficiency Boost: Versatility in material handling reduces downtime and increases productivity across packaging lines.

The key is fine-tuning the machine so both thin (50 μm) and thick (100 μm) films are cut cleanly, without waste or downtime. Let’s look at how to switch settings correctly.

Switching 50 μm → 100 μm: roller pressure, temperature (hot-knife), speed adjustments

Thin bubble wrap is flexible and easy to cut, while thicker film requires more force and heat. Without adjustments, operators face issues like slipping rollers, incomplete sealing, or blade wear.

When switching from 50 μm to 100 μm film, increase roller pressure4, raise hot-knife temperature, and reduce cutting speed5 for consistent quality.

Here’s a breakdown of what to change:

1. Roller Pressure

- 50 μm film:

Needs light roller pressure. Too much will crush the bubbles and deform the film. - 100 μm film:

Requires higher roller pressure to ensure the material feeds evenly without slipping.

👉 On HAOXINHE Bubble Wrap Cutting Machines, roller tension can be adjusted with calibrated knobs or pneumatic controls for quick switching.

2. Hot-Knife Temperature

- 50 μm film:

Cut cleanly at 160–180°C. Higher temperatures risk melting through or burning edges. - 100 μm film:

Needs 200–230°C to seal edges properly without leaving frays.

👉 Always allow the machine to stabilize after temperature adjustments. Use test cuts before starting full production.

3. Cutting Speed

- 50 μm film:

High speed is possible (80–120 cuts/minute). - 100 μm film:

Reduce speed (50–80 cuts/minute) to give rollers and heaters enough time to process thicker material.

👉 On PLC-controlled machines6, you can preset speed profiles for different film thicknesses, saving operator time.

Practical Adjustment Table

| Parameter | 50 μm Film | 100 μm Film |

|---|---|---|

| Roller Pressure | Low (light grip) | Medium–High |

| Hot-Knife Temp | 160–180°C | 200–230°C |

| Cutting Speed | 80–120 cuts/min | 50–80 cuts/min |

| Edge Quality | Clean, thin edges | Sealed, strong cut |

Real Example

A Singaporean packaging supplier running both thin protective wrap (50 μm) and heavy-duty wrap (100 μm) faced quality issues with their old machine. After upgrading to a HAOXINHE Hot Knife Bubble Wrap Cutting Machine with PLC presets, they were able to switch thicknesses in under 5 minutes by adjusting roller tension, temperature, and speed through the touchscreen.

This reduced film waste by 12% and cut operator training time in half.

Conclusion

A bubble wrap cutting machine can handle multiple film thicknesses, but success depends on adjusting roller pressure, hot-knife temperature7, and cutting speed.

🧠 Industry Insight: Handling Multiple Film Thicknesses with One Cutting Machine

From real-world factory visits, one issue I see too often is misalignment between material specs and machine flexibility. Operators try to cut both thin and thick bubble wrap on machines tuned for just one thickness—this leads to warped edges, cut errors, and unnecessary downtime.

Modern, industrial-grade machines—like those from HAOXINHE—solve this with true multi-thickness capability, but only when operators understand how to recalibrate the machine dynamically. Most brands advertise “0.1–3mm” support, but in reality, without adjustable roller tension and programmable heat zones, the results fall short.

One veteran packaging line supervisor once told me, “If I can’t retool the machine in 5 minutes for the next job, it’s not really multi-thickness.” That’s the benchmark to aim for.

Pro tip: Use a quick-change preset system via PLC to switch between material profiles. Store parameters like pressure, temperature, and feed speed per film type. This reduces human error and slashes changeover time.

Versatility isn’t just about cutting—it’s about transitioning between jobs without halting the entire line.

Factories often cut both 50 μm and 100 μm bubble wrap films. Machines that lack adjustable rollers, temperature control, or speed presets cause waste and downtime. At Suzhou Haoxinhe Electrical Equipment Co., Ltd.8, our Bubble Wrap Cutting Machines and Protective Foam Cutting Machines include PLC-controlled settings, adjustable roller systems, and hot-knife temperature7 control, making them ideal for multi-thickness operations.

Explore this link to discover top-rated machines that can efficiently handle various film thicknesses. ↩ ↩

Learn about the importance of flexible configurations for adapting to different packaging needs. ↩

This range is crucial for selecting the right machine for your packaging requirements. ↩

Discover how adjusting roller pressure can improve cutting efficiency and edge quality. ↩

Explore the relationship between cutting speed and production efficiency for bubble wrap. ↩

Find out how PLC control can enhance precision and reduce changeover time in production. ↩

Learn about the optimal temperatures for different film thicknesses to ensure clean cuts. ↩ ↩

Explore their innovative solutions for efficient bubble wrap cutting and packaging. ↩