Buying Guide: How to Choose the Best Bubble Wrap Cutting Machine for Your Business

Choosing the right bubble wrap cutting machine ensures faster packing, cleaner cuts, and lower operating costs.

This guide walks you through machine types, key features, and practical buying tips — backed by industrial experience from Suzhou Haoxinhe.

Why You Need a Bubble Wrap Cutting Machine

Cutting bubble wrap by hand is slow, inconsistent, and wasteful.

A dedicated machine offers:

- ✔ Up to 10× faster production

- ✔ Waste reduction up to 25%

- ✔ Lower labor costs and training requirements

- ✔ Professional sheet consistency

- ✔ Works with multiple roll types and widths

Step 1 — Determine Your Production Volume

| Output Per Day | Best Suitable Machine |

|---|---|

| Under 500 sheets | Manual or low-speed electric cutter |

| 500–2,000 sheets | Semi-automatic with memory presets |

| 2,000+ sheets | Fully automatic cutter (Haoxinhe BWC Series) |

Tip: If you expect growth — choose one model higher to avoid future bottlenecks.

Step 2 — Bubble Wrap Roll Specifications

Check compatibility based on:

| Spec | Common Options |

|---|---|

| Width | 300–1500mm |

| Bubble diameter | 6mm / 10mm / 20mm |

| Material | Standard / Anti-static / Foam-lined |

| Paper core | 76mm standard |

Adjustable tension control is a must for industrial-grade output.

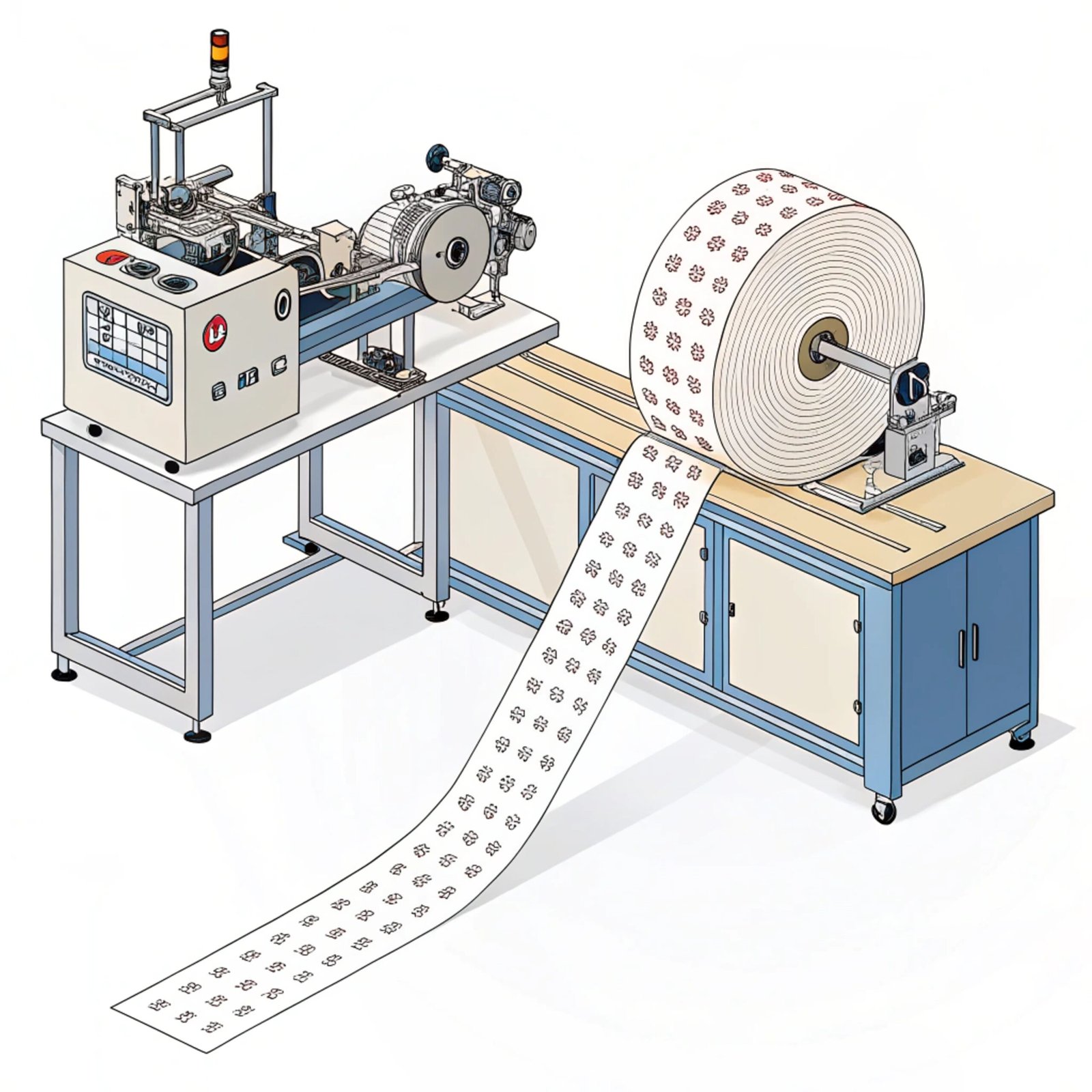

Step 3 — Manual vs Semi-Auto vs Fully Auto Machines

| Feature | Manual | Semi-Auto | Fully Auto |

|---|---|---|---|

| Cutting Speed | 2–3/min | 5–6/min | 10–15/min |

| Accuracy | ±10mm | ±3mm | ±1mm |

| Operators | 2 | 1 | 1 manages multiple lines |

| Length presets | ❌ | ✔ | ✔ |

| Best For | Low volume | Growing factories | High-speed production |

Step 4 — Key Features to Look For

Must-have functions for bubble wrap conversion lines:

- Touchscreen interface + job memory

- Accurate programmable cutting

- Cold + hot blade options

- Perforated cutting for easy tearing

- Multi-width roll support

- Smart diagnostics + output counter

- Compact footprint for small facilities

Step 5 — Maintenance, Support & ROI

Ask these before confirming your purchase:

- Warranty duration and spare kit included?

- Remote setup + video training available?

- Local language technical support?

- Delivery time and parts availability?

- ROI vs current labor and waste?

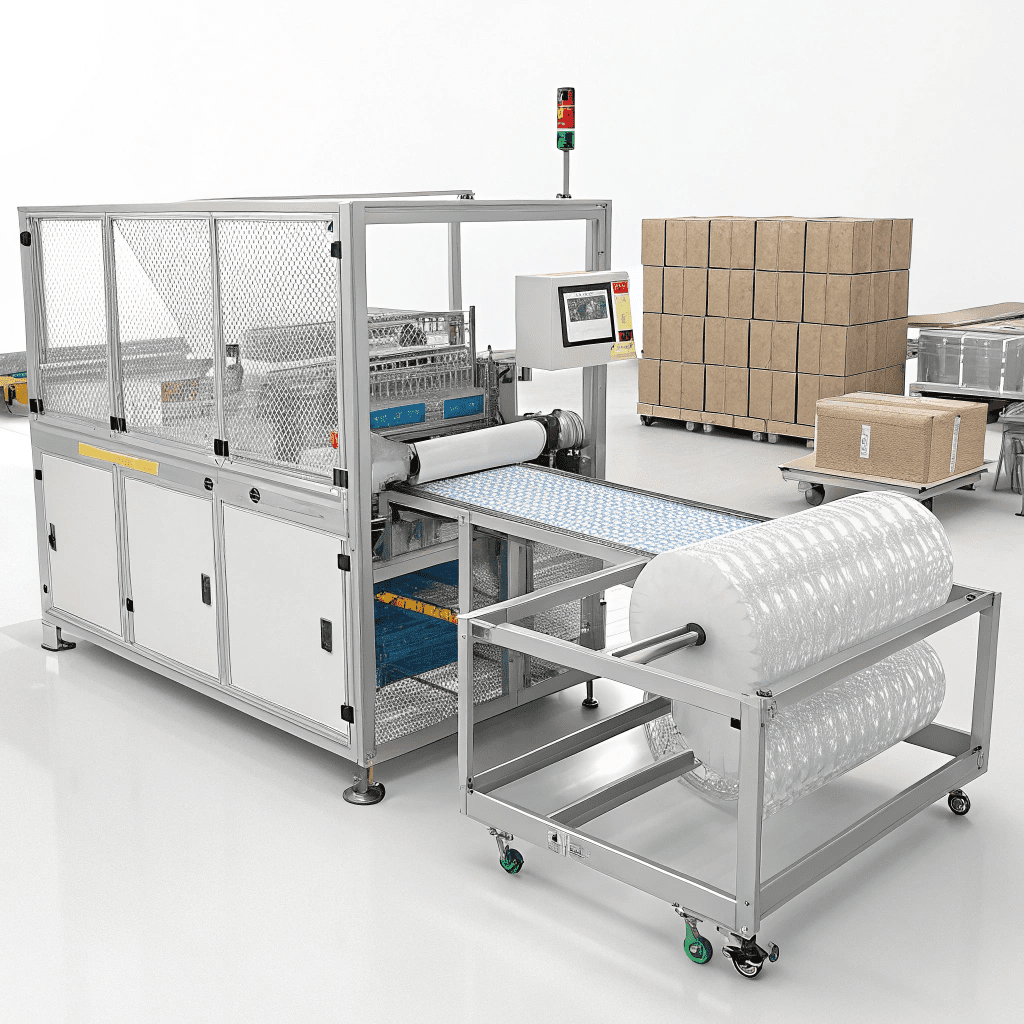

Why Choose Suzhou Haoxinhe?

Suzhou Haoxinhe Electrical Equipment Co., Ltd. is a CE/ISO-certified manufacturer trusted by logistics, electronics, and furniture factories worldwide.

What You Gain with Haoxinhe Machines

- 💨 10,000+ sheets/day speed

- 🧩 Adjustable widths 300–1500mm+

- ✂ Cold / Hot / Perforation cutting

- 🖥 Touchscreen automation presets

- 📦 Global shipping 7–15 days

- 🔧 12-month warranty + spare kits included

- 🌍 Multilingual remote support

We also produce Velcro dot cutters, foam cutters, ribbon slitting machines, and more.

Conclusion

Choosing the right bubble wrap cutting machine ensures faster packing, cleaner cuts, and stronger efficiency.

Match production volume, roll specifications, and automation level — and your packaging line will scale effortlessly.

FAQ – Bubble Wrap Cutting Machine Buying Questions

Q1: What is the price range of a bubble wrap cutter?

Pricing depends on width and automation: $1,500–$18,000 typical range.

Q2: Can machines cut anti-static bubble wrap?

Yes. Our BWC Series supports ESD, foam-lined, and specialty films.

Q3: What is the cutting accuracy for industrial machines?

Fully automatic models reach ±1mm precision.

Q4: How fast can it cut?

Up to 10–15 cuts/min, depending on length and material.

Q5: Is customization available?

Yes — we support OEM/ODM, custom widths, and feeding options.

Ready to upgrade your packaging line?

📩 Contact Suzhou Haoxinhe today

We’ll match you with the ideal bubble wrap cutting solution for your factory.

👉 https://hxcuttingmachine.com/contact-us/

👉 WhatsApp: +86 18100615234