Behind the Scenes: How Our Machine Produces Thousands of Velcro Dots per Hour?

The production of thousands of Velcro dots per hour involves a highly automated, precise manufacturing process with several key stages:

Raw Material Preparation and Weaving

Nylon yarn is first spun and warped, then woven into base tape fabric on specialized looms, forming the foundational strip for Velcro products[1][2].Dyeing and Sizing

The woven tape undergoes high-temperature dyeing to achieve the desired color, followed by sizing treatments that prepare the surface for further processing and enhance durability[1][2].Hook Formation and Loop Surface Treatment

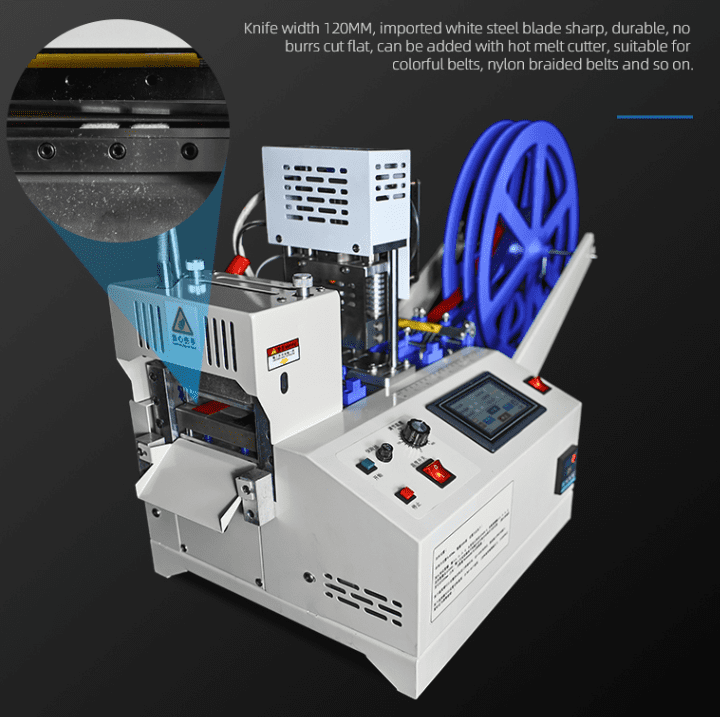

For the hook side, nylon monofilaments are inserted and precisely cut by imported cutting machines to create uniform tiny hooks that provide the fastening function. The loop side is brushed to raise the fibers, creating a soft looped surface[1][2].Kiss Cutting of Velcro Dots

The continuous adhesive Velcro tape is fed into a kiss cutting machine that precisely cuts Velcro dots or shapes without cutting through the release paper backing. This machine uses high-precision servo motors and customized plastic knife molds to achieve cutting depth accuracy up to 0.001mm, ensuring clean, consistent dots[5].Automatic Separation and Collection

The kiss cutting machine automatically separates the cut Velcro dots from the waste material. Both the finished Velcro dots and the waste backing are collected onto separate rolls using powered rollers and sensors to maintain tension and alignment, facilitating easy packaging and minimal material waste[5].Quality Control and Packaging

The finished Velcro dots are inspected for quality and consistency before being rolled and packaged for shipment. The entire process is monitored and controlled via touch screen systems to ensure efficiency and precision[5].

This integrated system—from raw yarn to finished Velcro dots—combines advanced weaving, dyeing, cutting, and automated handling technologies to produce thousands of Velcro dots per hour with high accuracy and minimal waste.

Every minute matters when you’re producing in bulk — but have you ever wondered how Velcro dots are cut with speed and accuracy?

Our high-speed Velcro dot cutting machine combines precision engineering with automation to deliver thousands of perfectly cut dots per hour — no manual intervention needed.

What you’re about to read is a behind-the-scenes look at how Suzhou Haoxinhe Electrical Equipment Co., Ltd. turns rolls of Velcro into consistent, adhesive-ready dots using smart design and cutting-edge automation.

What kind of machine cuts Velcro into dots?

Many suppliers claim their machines can cut Velcro, but not all machines are built for circular precision or high-volume output.

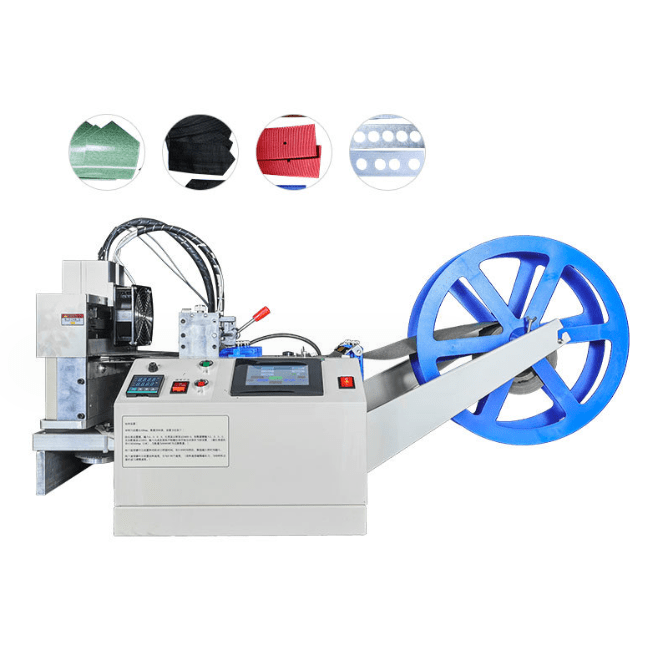

The Velcro dot cutting machine is a specialized automatic rotary die-cutting system designed to cut circular shapes at high speed without damaging the material.

Components that Make It Work

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., our machine features:

- Rotary Bevel Cutting Mechanism: Designed for precise, circular cuts.

- Roll Feeding System: Feeds material with zero wrinkles or misalignment.

- Automatic Tension Control: Keeps the cutting accurate, even at high speed.

- Vacuum Waste Removal: Removes excess material cleanly.

- Programmable Interface: Allows quick changeover between different dot sizes.

How It Outperforms Traditional Cutting

| Feature | Manual Cutting | Standard Die Cutter | Haoxinhe Velcro Dot Cutter |

|---|---|---|---|

| Speed | 100-300 pcs/hr | 500-1000 pcs/hr | 10,000+ pcs/hr |

| Accuracy | Low | Medium | High (±0.2mm) |

| Labor Requirement | 2-3 workers | 1-2 workers | Fully automated |

This machine is especially useful for clients in packaging, apparel, medical devices, and stationery industries that rely on mass use of hook-and-loop fasteners.

How does it cut thousands of dots without error?

Cutting thousands of dots sounds simple — until you try doing it quickly, consistently, and with zero material waste.

Our machine uses servo-driven precision control with feedback loops to cut at speeds exceeding 10,000 dots/hour with 99.98% consistency.

Inside the Speed Logic

There are a few key tech innovations that help us achieve both speed and accuracy:

1. Servo Motor Synchronization

Each action — from feeding to cutting — is controlled by servo motors, which ensures:

- Exact position tracking

- Minimal vibration

- No lag between feed and cut

2. Intelligent Sensors

Sensors detect material thickness, dot alignment, and waste edge position, allowing for automatic calibration even when:

- Materials stretch

- Rolls are misaligned

- Dot sizes change

3. Heat or Cold Cutting Mode

Depending on whether you use nylon-based or polyester Velcro, our hot and cold cutting machine adapts to prevent fraying. This flexibility also reduces your need for post-processing.

All of this is embedded into a one-button operation interface, so the operator only needs to load the roll and hit “Start.”

Can one machine produce different sizes of Velcro dots?

In bulk production, flexibility is key. Clients often request multiple diameters of Velcro dots in one order.

Yes — our rotary die-cutting machine features a fast-switch system for different dot sizes, making it easy to run varied jobs without downtime.

Modular Cutter Design

Our machines are equipped with replaceable rotary dies, which can be switched within 5 minutes. Here’s how:

- Pull out the die module

- Insert new die (different diameter or shape)

- Auto-align and calibrate through the software

This means manufacturers don’t need to buy multiple machines for different sizes — a huge cost saver for medium to large-scale buyers.

Common Velcro Dot Sizes We Support

| Diameter (mm) | Typical Use Case |

|---|---|

| 10mm | Stationery & crafts |

| 15mm | Clothing labels |

| 20mm | Packaging seals |

| 25mm | Industrial bundling |

| 30mm+ | Medical strapping |

Custom shapes — such as rounded squares, stars, or logos — can also be supported with a custom die.

Suzhou Haoxinhe Electrical Equipment Co., Ltd. offers custom tooling services for clients who want branded or unique dot designs.

What are the cost and time benefits for my business?

You don’t just save time — you save money, labor, and wasted material.

Switching to our Velcro dot cutting machine reduces production costs by up to 60% and shortens job time from hours to minutes.

Real Case Scenario

One of our Canadian clients was outsourcing dot-cutting to a third-party processor. Their costs included:

- $0.02 per dot in labor

- $500 monthly shipping to and from processor

- 5–7 days turnaround time

After switching to our Velcro dot cutting machine, their numbers changed:

- Labor cost: almost zero (fully automatic)

- No extra shipping

- Production completed same-day

- ROI reached in 5 months

Summary of Benefits

| Metric | Before Machine | After Machine |

|---|---|---|

| Unit Cost | $0.03 | $0.008 |

| Daily Output | 1,000 pcs | 12,000 pcs |

| Operators Needed | 2 | 0.5 |

| Downtime | High | Near-zero |

This means you get more control over your production, fewer delays, and a better profit margin.

Conclusion

Our Velcro dot cutting machine transforms rolls into thousands of precise, consistent dots — saving you time, labor, and money.

Insights

If you’re still cutting Velcro dots manually or relying on third-party processors, you’re spending more than you should. Suzhou Haoxinhe’s webbing ribbon cutting machine with rotary die cutting enables businesses to produce 10,000+ dots per hour, with 99.98% consistency, while reducing per-unit costs by up to 60%. This solution is ideal for manufacturers in packaging, textiles, and medical industries who need precision, flexibility, and speed. Contact us today to learn how you can bring this automation in-house.