Automatic vs Manual Bubble Wrap Cutting Machines: Which One Is Right for Your Factory?

Packaging teams face a tough decision — speed or control? Simplicity or automation?

Choosing between an automatic and manual bubble wrap cutting machine depends on your factory’s volume, labor availability, and precision needs.

Let’s compare the two side-by-side to help you decide which solution fits your workflow and budget.

What’s the difference between automatic and manual cutters?

Both machines are designed to prepare bubble wrap for packaging — but the level of automation changes how they work.

Manual cutters require operators to feed and cut wrap by hand using a mechanical blade, while automatic machines feed, measure, and cut the wrap without manual steps.

Operation Comparison

| Feature | Manual Cutter | Automatic Cutter |

|---|---|---|

| Feeding | Manual pull | Motorized roller |

| Cutting | Lever, blade, or rotary | Auto blade or hot knife |

| Length Setting | Estimation or scale marks | Programmable by touchscreen |

| Output Speed | 2–3 sheets/min | 5–10+ sheets/min |

| Supervision | Constant | Minimal |

Now, let’s dive into when each machine makes the most sense.

When should you use a manual bubble wrap cutter?

Manual machines are simple, low-cost tools — ideal for small-scale operations or low-frequency packaging tasks.

Choose a manual cutter if your factory handles small volumes, or needs a portable, low-maintenance tool.

Best For

- Startups or micro-factories

- On-demand packing of odd-sized items

- Single-operator stations

- Budget-conscious teams

- Occasional use (not all-day operation)

Pros

- Low upfront cost

- Portable and compact

- No electricity required

- Easy to maintain

Cons

- Inconsistent cut lengths

- Slower output

- Higher labor cost

- Difficult to scale for larger orders

Manual machines may work well for custom packaging lines, small-batch producers, or seasonal fulfillment centers.

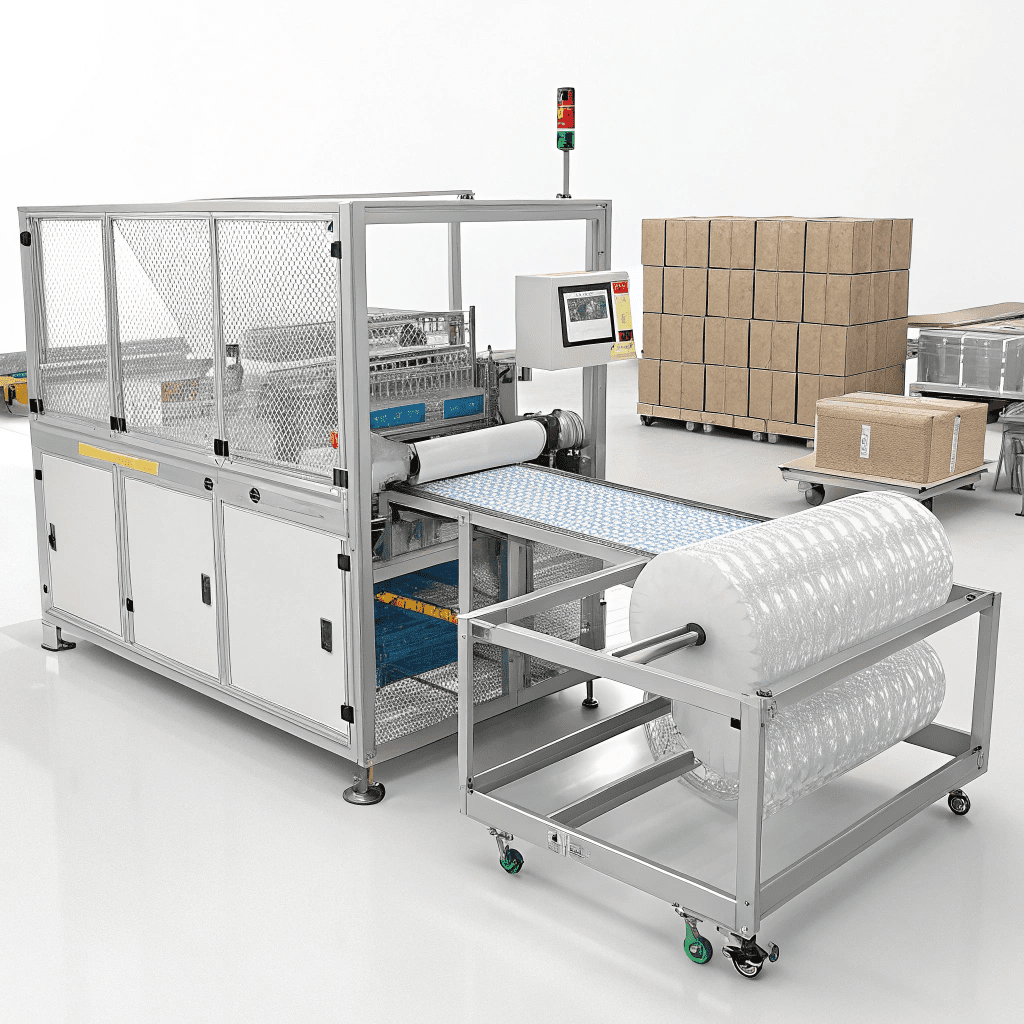

When is an automatic bubble wrap cutter the better choice?

As orders increase, manual wrap cutting becomes a bottleneck — costing time, labor, and wrap material.

Automatic machines handle high volumes with speed and consistency, making them ideal for medium to large-scale factories.

Best For

- High-throughput assembly lines

- Electronics, furniture, appliance, or 3PL warehouses

- Multi-operator packing stations

- Multiple wrap sizes per shift

- Consistent product SKUs

Pros

- Programmable length control

- Less waste, cleaner cuts

- Higher speed and lower labor need

- Seamless integration into existing lines

- Works with wide-format rolls (up to 1500mm)

Cons

- Higher upfront investment

- Requires power and setup

- Takes up more space

Factories shipping fragile, valuable, or standardized products benefit most from automation.

Head-to-head comparison

Here’s a side-by-side summary to help you evaluate which machine suits your environment.

| Feature | Manual Cutter | Automatic Cutter |

|---|---|---|

| Cutting Speed | 2–3 sheets/min | 10,000+ cuts/day |

| Labor Need | High (1 per station) | Low (1 for multiple stations) |

| Accuracy | ±10–20mm | ±1–2mm |

| Material Waste | 10–25% | <5% |

| Ideal Use | Low volume, flexible sizes | High volume, repeatable tasks |

| Maintenance | Minimal | Light routine care |

| Initial Cost | Low | Higher upfront, faster ROI |

| Setup Time | Plug and play | Short training, programmable interface |

In most growing factories, automation pays for itself in 3–6 months through labor and material savings alone.

What does Suzhou Haoxinhe offer?

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we build both manual-style and automatic cutting solutions — so you choose what fits.

Our Bubble Wrap Cutting Machine Options

| Model | Type | Ideal For |

|---|---|---|

| HXN-BWC1500M | Manual | Compact spaces, low-volume use |

| HXN-BWC1000A | Automatic | Standard factory lines |

| HXN-BWC1500P | Auto + Perforation | High-speed wrapping with tear-line sheets |

| HXN-R2R | Roll-to-Roll Auto | Industrial-scale packaging integration |

Why Partner With Us?

- CE & ISO certified machinery

- 7–15 day global shipping

- Multilingual sales and support

- Custom widths, blade styles, and speeds

- Remote training + setup videos

We also offer:

- Velcro dot and foam cutters

- Protective packaging equipment

- Webbing ribbon and PVC edge cutting machines

Clients in electronics, logistics, furniture, and medical sectors use our equipment for packaging up to 20,000 units/day — faster, safer, and more cost-effectively.

Conclusion

If you’re packing low volumes and need simplicity, go manual. If speed, precision, and volume matter — automatic is the way to go.

Let your factory’s scale and goals guide your decision.

Insights

Manual bubble wrap cutters suit small-scale or flexible packing. Automatic cutters deliver speed, accuracy, and efficiency at scale. Suzhou Haoxinhe offers both — helping factories choose the right fit based on volume, labor, and packaging goals.