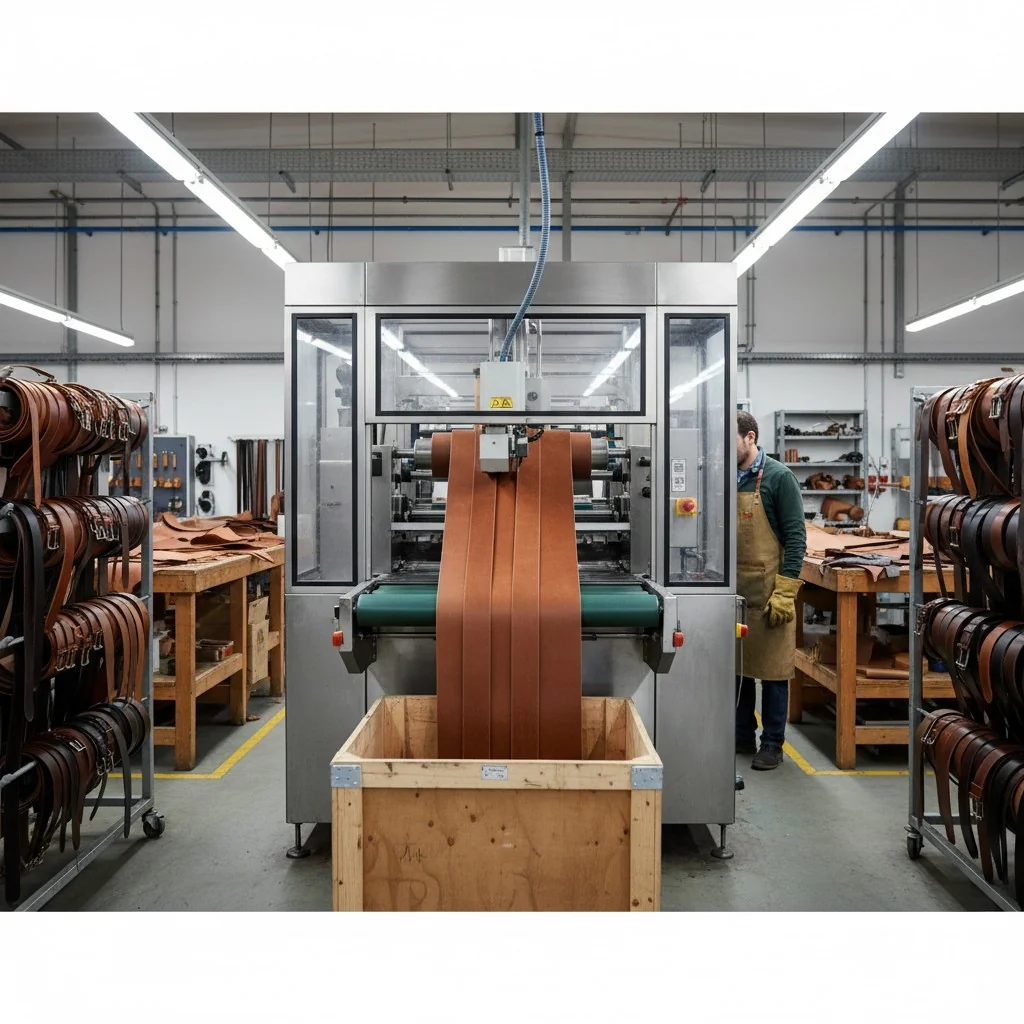

Can automated cutters reduce labor time for belt leather fabrication?

Can automated cutters reduce labor time for belt leather fabrication? Leather belt manufacturers often lose production hours to slow hand-cutting and poor edge consistency that result in high defect rates. Yes—automated cutters significantly reduce labor time in leather belt fabrication by delivering fast, precise cuts at scale, with reduced waste and minimal manual handling. 1: […]

Can an auto ribbon cutter reduce waste in luxury gift packaging?

Can an auto ribbon cutter reduce waste in luxury gift packaging? Inconsistent ribbon lengths and frayed ends are common problems in luxury packaging—leading to material waste and poor presentation. Yes—an automatic ribbon cutter reduces waste by delivering consistent lengths, sealing edges cleanly, and eliminating manual errors in premium gift wrapping lines. An auto ribbon cutter […]

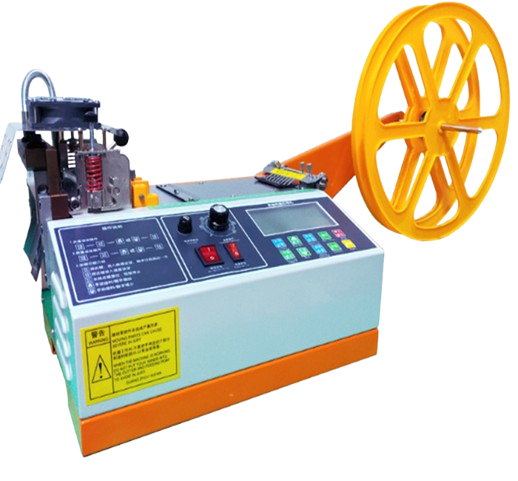

How Does a Webbing Punch Hole Machine Work?

How Does a Webbing Punch Hole Machine Work? If you don’t understand how it works, you can’t choose the right machine for your factory. A webbing punch hole machine works by feeding webbing material into a die set, then applying force with a punch head to cut clean holes at precise positions. A punch and […]

How to Maintain a Webbing Punch Hole Machine for Long-Term Use?

How to Maintain a Webbing Punch Hole Machine for Long-Term Use? A neglected machine will cost you more in downtime than the price of regular care. Maintain a webbing punch hole machine1 by lubricating moving parts, inspecting dies, cleaning daily, and scheduling preventive maintenance every 3–6 months. Regular maintenance is key to extending the lifespan […]

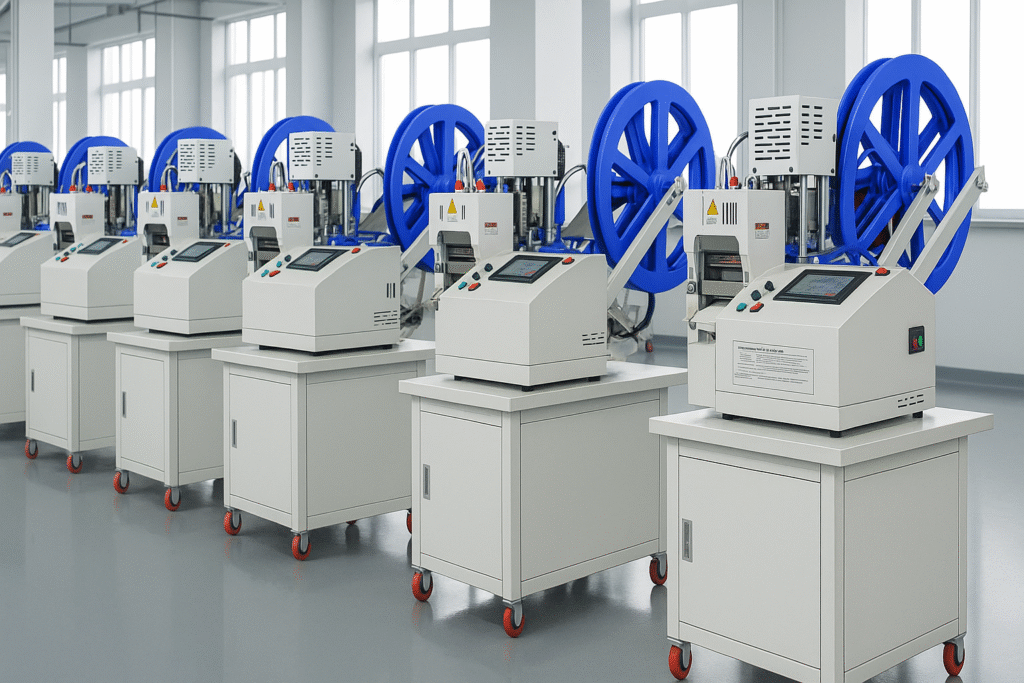

How Much Does a Webbing Punch Hole Machine Cost?

How much does a webbing punch hole machine1 cost? Without a clear price range, many buyers waste time chasing quotes that don’t match their project needs. A webbing punch hole machine1 typically costs between $2,500 and $15,000, depending on its punching force, automation level, and customization features. 1: A webbing punch hole machine1 typically ranges […]

What Are the Safety Precautions When Using a Webbing Punch Hole Machine?

What are the safety precautions when using a webbing punch hole machine1? Accidents in the factory are expensive—not just financially, but also for team morale and business continuity. To operate a webbing punch hole machine1 safely, follow lockout-tagout procedures, wear proper PPE2, install emergency stops3, and train all staff on safe machine operation. 1: Always […]

Noise reduction techniques for industrial dog collar punching?

Noise reduction techniques for industrial dog collar punching? Loud machine noise is more than annoying—it’s a health risk and a productivity killer in your factory. To reduce noise in dog collar punching, upgrade to servo-driven systems1, use sound-dampening materials, and regularly maintain your machine parts. 1: Modify the punching process by optimizing machine parameters to […]

Can a Webbing Punch Hole Machine Handle Different Material Thicknesses?

Can a webbing punch hole machine1 handle different material thicknesses2? Using the wrong punch press on the wrong thickness can damage the machine—or worse, injure the operator. Yes, modern webbing punch hole machine1s can handle a wide range of thicknesses, from 1 mm to over 10 mm, with proper tonnage and die setup. 1: A […]

Which brands of bubble wrap cutting machines are reliable for continuous duty?

Which brands of bubble wrap cutting machines are reliable for continuous duty? Factories running high-output packaging lines face a tough problem: some machines fail after a few months, forcing downtime and costly repairs. Reliable bubble wrap cutting machine brands for continuous duty are those offering strong build quality, fast service, and quick spare part delivery—especially […]

How to choose a bubble wrap cutting machine for factory use?

How to choose a bubble wrap cutting machine for factory use? Many factories struggle to scale because their cutting process is slow, inconsistent, or wastes material. This kills productivity and profitability. For a factory handling bubble wrap, choosing the right cutting machine depends on order volume, labor availability, and the level of automation required to […]

Are automatic paper cutters improving throughput in print-on-demand plants?

Are automatic paper cutters improving throughput in print-on-demand plants? Print-on-demand factories are losing money every hour to slow, manual cutting processes that create delays and pile up rework. Yes—automatic paper cutters significantly increase throughput in print-on-demand plants by reducing downtime, improving cut precision, and eliminating bottlenecks in finishing operations. 1: Automatic paper cutters are transforming […]

How are wire stripping machines revolutionizing electric vehicle production?

How are wire stripping machines1 revolutionizing electric vehicle production? Electric vehicle manufacturers are struggling with complex, high-voltage wiring systems—slow, manual stripping creates a serious production bottleneck. Wire stripping machines are transforming EV production by delivering faster, safer, and more consistent cable preparation2, especially for thick and high-voltage cables. 1: Wire stripping machines are revolutionizing electric […]