Top 10 Chinese Manufacturers of Bubble Wrap Cutting Machines (Factory Direct Options)

Top 10 Chinese Manufacturers of Bubble Wrap Cutting Machines (Factory Direct Options) Tired of middlemen and overpriced machines with questionable support? This 2026 list introduces 10 trusted Chinese manufacturers of bubble wrap cutting machines that offer factory-direct prices, international shipping, and export-ready support. If you’re sourcing from China for resale or direct use, these are […]

How to operate a bubble wrap cutting machine safely?

How to operate a bubble wrap1 cutting machine safely? Bubble wrap cutting machines can be dangerous if safety standards are ignored. Poor training or missing safeguards can lead to serious injuries. Safe operation requires compliance with CE or UL standards, use of emergency stops, proper guarding, interlocks, and consistent PPE use. Safe Operation Starts with […]

Best Budget vs. Premium Bubble Wrap Cutting Machines: 2026 Top 10 Review

Best Budget vs. Premium Bubble Wrap Cutting Machines: 2026 Top 10 Review Looking for the perfect bubble wrap cutting machine1, but not sure if you should save or splurge? In this 2026 review, I compare the top 10 budget and premium bubble wrap cutting machine1s so you can choose based on value, not just price. […]

What Are the Top Brands for Webbing Punch Hole Machines?

What are the top brands for webbing punch hole machines? With so many manufacturers claiming "industrial-grade" performance, it’s hard to know who to trust. Top webbing punch hole machine brands1 include Suzhou Haoxinhe2, JOMAR, Cutex, and LIHIT. Each offers different strengths depending on your production needs. 1: Suzhou Haoxinhe2‘s automatic webbing punching machines3 stand out […]

Top-Rated Bubble Wrap Cutting Machines for E-commerce Fulfillment Centers

Top-Rated Bubble Wrap Cutting Machine1s for E-commerce Fulfillment Centers Fulfilling e-commerce orders fast but still hand-cutting bubble wrap? The top-rated bubble wrap cutting machines2 of 2025 help fulfillment centers save time, reduce waste, and automate packaging workflows for faster order processing. If your fulfillment center handles hundreds or thousands of parcels daily, investing in a […]

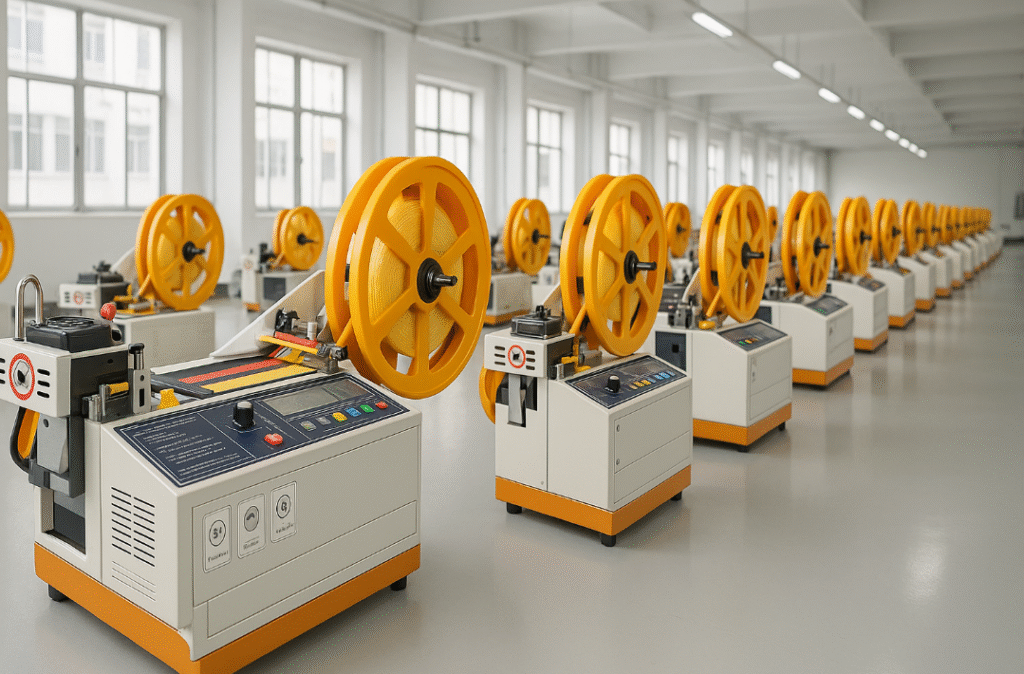

Why is roll-to-sheet cutting the future in flexible packaging lines?

Why is roll-to-sheet cutting the future in flexible packaging lines? Flexible packaging lines suffer from jammed web tension, imprecise cuts, and inconsistent panel lengths—especially when scaling high-speed runs. Roll-to-sheet cutting1 ensures higher throughput, cleaner edges, and format flexibility2, making it the go-to solution for modern flexible packaging3 production. 1: Roll-to-sheet cutting1 is revolutionizing flexible packaging […]

Can a bubble wrap cutting machine process other materials?

Can a bubble wrap cutting machine process other materials? Many buyers assume a bubble wrap cutter is a one-trick pony. But with the right settings and blade, you might get more than you paid for. Yes, most bubble wrap cutting machines1 can handle similar soft materials like PE foam2, PET film3, and kraft paper4—if the […]

How to select a rewinder/cutting combo for bubble wrap rolls?

How to select a rewinder/cutting combo for bubble wrap rolls? Choosing the wrong rewinder-cutter combo can wreck your workflow. Your bubble wrap might feed crooked, wrinkle, or jam — even if your cutter is perfect. To select the right combo, you must match the rewinder’s core specs, torque control, and lay-on mechanism with the cutter’s […]

What noise level should you expect on a bubble wrap cutter?

What noise level should you expect on a bubble wrap cutter? You turn on your new bubble wrap cutter — and suddenly the entire room sounds like a factory floor. Is that normal? Or a design flaw? Most industrial bubble wrap cutting machines operate between 65–85 dB(A), depending on the cutting mechanism. Some can get […]

How to minimize downtime on bubble wrap cutting machines?

How to minimize downtime on bubble wrap cutting machines? When your bubble wrap cutting machine suddenly stops mid-shift, every minute costs money. Downtime kills efficiency, delays orders, and frustrates your production team. To minimize downtime, you need to switch from reactive to predictive maintenance. That means using real-time counters and I/O sensors to detect issues […]

How do temperature and humidity affect cutting quality?

How do temperature and humidity affect cutting quality? Cutting machines don’t operate in a vacuum — literally. Environmental conditions like temperature and humidity change everything, especially when you’re cutting precision materials. Both temperature and humidity can warp material properties, alter cutting pressure requirements, and affect knife sharpness and tension control — leading to uneven edges […]

What’s the difference between “bubble wrap cutter” and “air bubble film cutting machine”?

What’s the difference between “bubble wrap cutter” and “air bubble film cutting machine”? People often use “bubble wrap cutter” and “air bubble film cutting machine” as if they mean the same thing — but they don’t. And the difference matters. A “bubble wrap cutter” usually refers to a manual or semi-automatic tool for simple cutting, […]