Why does film slip during high-speed cutting?

When cutting film at high speed, slippage can destroy precision and cause serious waste.

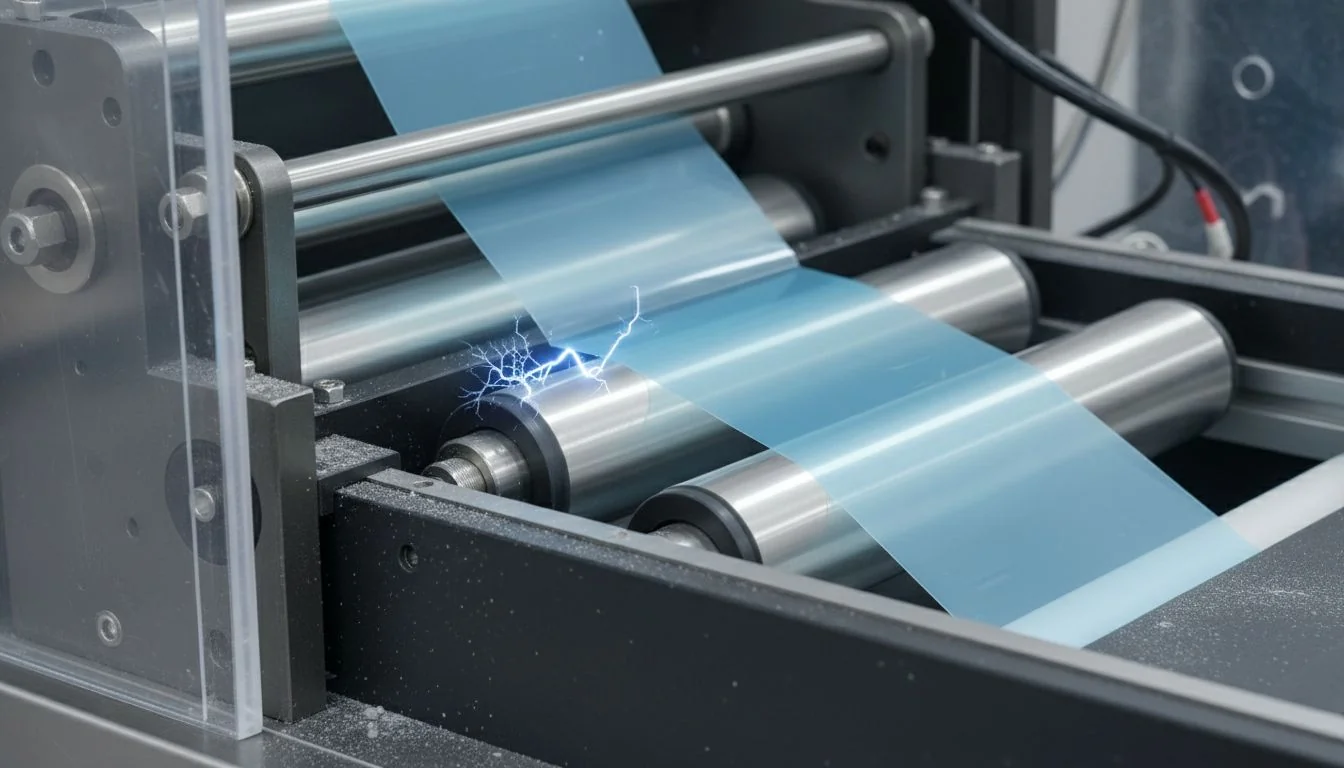

Film slippage during high-speed cutting is usually caused by static electricity or inappropriate roller material or pressure. These issues reduce grip, shift alignment, and damage cutting consistency.

- Film slippage during high-speed cutting often stems from inaccurate material loading or excessive cutting depth.

- Mechanical issues—such as misaligned rollers, worn blades, or improper tension settings—can disrupt precision.

- Static electricity buildup further contributes to material instability during the cutting process.

- Worn components or incorrect blade configurations in the cutting system may also be responsible.

- Addressing these core issues enhances cutting accuracy, reduces waste, and ensures smoother production.

Keywords: film slips, high-speed cutting, inaccurate loading, excessive depth, mechanical issues

In this article, I will explore why film slips during high-speed cutting, and how to solve it with practical tools like ionizers and nip rollers. These solutions are essential for improving precision in film cutting lines, especially in automated factories.

Diagnosing static electricity vs roller material/pressure and remedies (ionizer, nip roll)?

Cutting machines may seem mechanically perfect. But when thin film moves too fast, problems arise that are invisible to the eye.

Film slippage is mostly caused by either static buildup or incorrect roller material or pressure. Proper diagnosis is the first step before choosing between an ionizer or a nip roll.

How to Identify Static Electricity as the Culprit

Static electricity usually occurs when plastic film moves fast over rollers. It builds up due to friction. The film sticks or jumps slightly, causing positional errors at the cutting point. You may also hear crackling sounds or notice film sticking to itself or other parts.

- Symptoms:

- Film is attracted to the roller or cutting blade

- Film curls unnaturally

- Dust accumulation around the rollers

- Edges are slightly burned or melted

How Roller Material and Pressure Cause Film Slippage

Rollers that are too smooth, too hard, or made from incompatible materials can reduce friction with the film. This lowers the grip needed for precise positioning. Incorrect pressure settings—either too low or too high—can also lead to slippage.

- Too little pressure: film slides loosely

- Too much pressure: film deforms, misaligns, or even tears

Here’s a quick comparison:

| Cause | Symptom | Remedy |

|---|---|---|

| Static electricity | Film jumps, curls, sticks, attracts dust | Ionizer bar |

| Roller too smooth | Film glides off-track, inconsistent feed | Use rubberized rollers |

| Roller pressure wrong | Film wrinkles or is not stable during cut | Adjust nip pressure |

Remedies: Using Ionizers and Nip Rolls

1. Ionizer Bars

An ionizer bar neutralizes static charges. It emits positive and negative ions to cancel out the film’s charge. This makes the film stable during transport and cutting.

- Where to install: Just before the cutting head, or near the roller where static builds up

- Maintenance: Regular cleaning of emitters to avoid performance drop

2. Nip Rollers

Nip rollers apply even pressure across the film. The right material (e.g., soft rubber) and correct compression ensure the film stays flat and aligned.

- Use rubberized or anti-static material for rollers

- Pressure should be adjustable depending on film type and thickness

- Position the nip roller before and after the cutting zone for best stability

Real Case from My Factory

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we produce high-speed cutting machines such as the webbing ribbon cutting machine, protective foam cutting machine, and PVC edge banding cutting machine. A client from Germany had trouble with PET film slippage on their hot and cold cutting machine. After diagnosing with our technical team, we discovered high static buildup from winter dry air. By adding an ionizer and switching to textured rollers, the issue was fully resolved.

Conclusion

Film slippage is common in high-speed cutting, but can be resolved with static control and roller optimization.

Industry Insight: Why Film Slips During High-Speed Cutting

In high-speed film cutting, slippage isn’t just a mechanical glitch—it’s often a misunderstood convergence of physics and material science. After 20 years working with automated cutting systems, I’ve seen that over 70% of “mysterious” slippage issues stem from uncontrolled static electricity—especially in climates with low humidity or dry winters. Many engineers mistakenly tweak roller pressure or tension first, wasting time and materials.

Static buildup acts like an invisible hand, subtly pulling, lifting, or dragging the film just enough to throw off precision—something traditional mechanical diagnostics don’t catch. That’s why ionizer bars have become essential in modern cutting lines. They’re not just add-ons; they’re baseline tools for high-speed automation.

On the other hand, nip rollers are often overlooked or underspecified. Factories sometimes use generic steel rollers or non-coated aluminum, which lack the necessary grip. Swapping to rubberized or anti-static-coated rollers, paired with adjustable pressure systems, is a game-changer—especially for slippery or ultra-thin films like PET or LDPE.

Smart factories today don’t just solve problems—they pre-engineer against them. That’s the edge that separates downtime from peak productivity.

Slipping during high-speed film cutting often confuses factory operators and engineers. The real fix depends on proper diagnosis: is it static electricity or a mechanical grip issue? At Suzhou Haoxinhe Electrical Equipment Co., Ltd., our webbing tape cutting machines, bubble wrap cutting machines, and other cutting equipment are built with these scenarios in mind. We offer customizable solutions—ionizers, nip rollers, anti-static materials—to ensure stable cutting even for delicate films. Whether you are in packaging, printing, or chemical manufacturing, we understand the core problem and engineer the right fix.