How to troubleshoot uneven or ragged cutting edges on bubble wrap?

When your machine cuts uneven edges on bubble wrap, it doesn’t just ruin material—it slows down production and frustrates your workers.

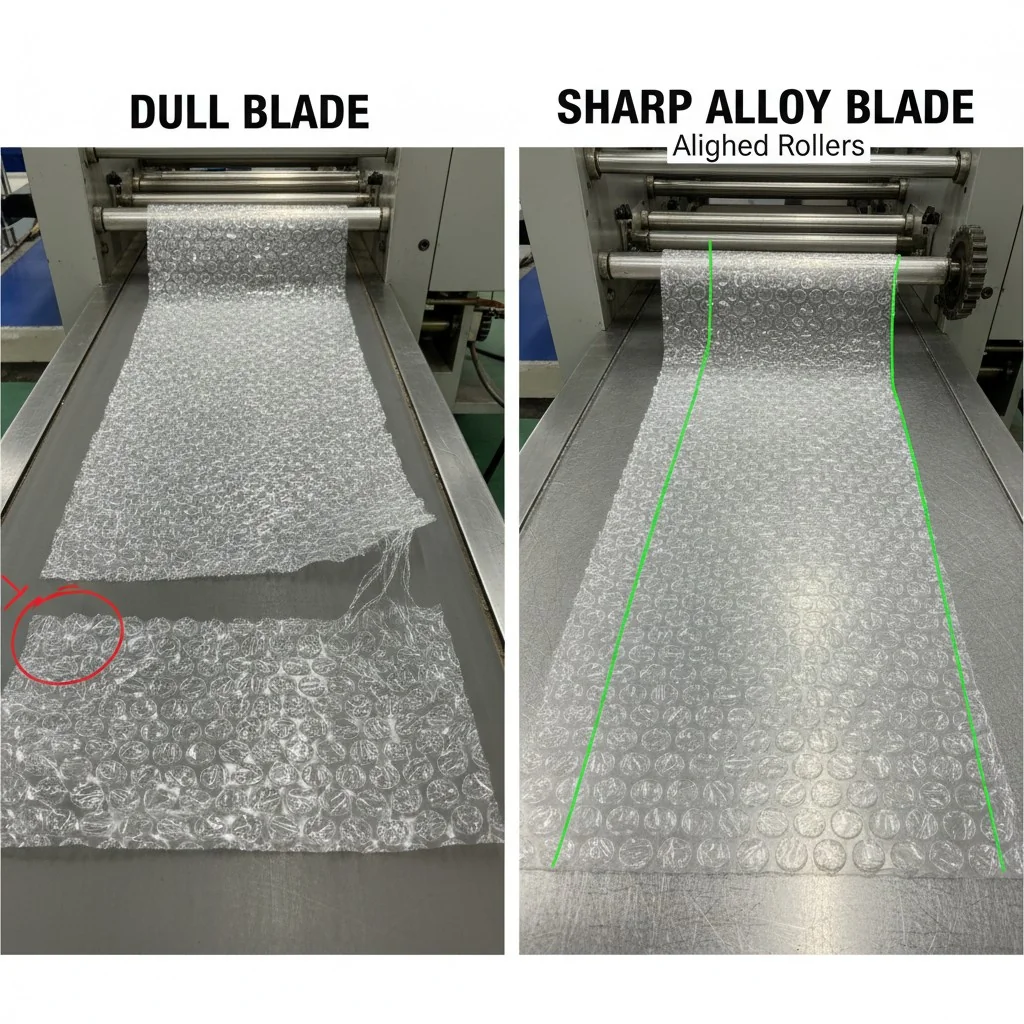

Uneven or ragged cutting edges on bubble wrap are usually caused by blade dullness, roller misalignment, or static interference. Diagnosing the root cause is the first step to solving the problem.

- Common Cutting Problems: Uneven or ragged edges on bubble wrap are typically caused by dull blades, roller misalignment, or static electricity.

- Blade Condition: Replace or sharpen blades regularly—dull edges create frayed or torn cuts and reduce efficiency.

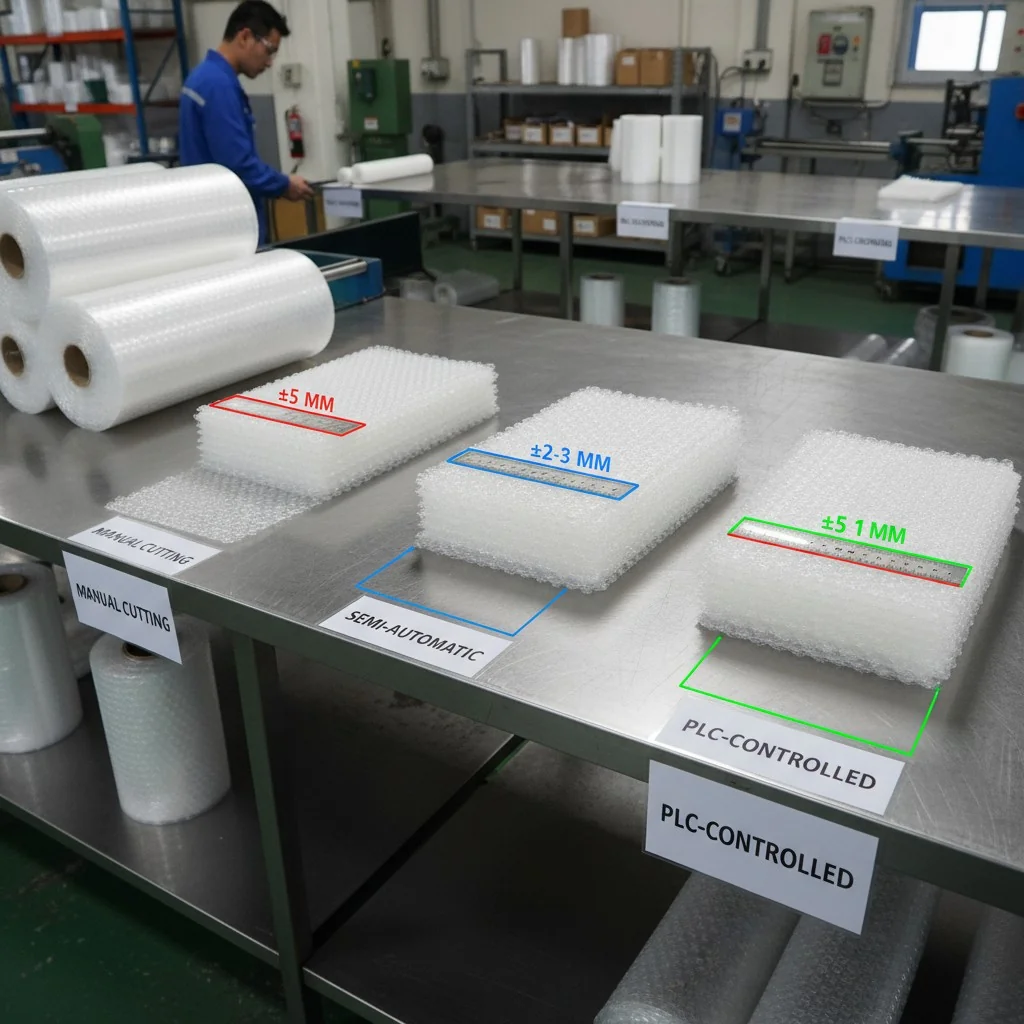

- Roller Alignment: Misaligned rollers shift the material, resulting in off-center or jagged cuts—check pressure and parallel positioning.

- Static Interference: In dry conditions, static causes film to cling or shift—use antistatic bars and maintain proper humidity.

- Industrial Solution: Choose machines with high-precision blades1, adjustable rollers, and static control to ensure clean, accurate cuts.

Let’s figure out what’s really behind the issue, and how to fix it before it affects your orders or customer satisfaction.

Is blade dullness, roller misalignment, or static the primary cause? (decision tree)

Uneven cuts can destroy product presentation. Are your customers noticing poor edge quality?

A simple decision tree can help isolate whether your bubble wrap cutting issue is caused by blade condition, roller setup, or static build-up. Fixing the right issue saves time and money.

Let’s break this down into clear steps and checks you can do today.

✅ Step-by-step Decision Tree

Here’s a quick visual guide to help you decide what’s wrong:

| Symptom | Likely Cause | Fix |

|---|---|---|

| Cuts are frayed or tearing unevenly | Dull blade | Replace blade or sharpen, clean adhesive buildup |

| Bubble wrap shifts before cutting | Roller misalignment | Adjust pressure rollers to maintain consistent tension |

| Cutting edges look melted or fuzzy | Static electricity | Install antistatic bar or ionizer, increase humidity |

| Inconsistent cuts during continuous feed | Blade height variation | Check blade holder and re-level cutting head |

| Clean cut at first, ragged later | Blade heating up | Use cooling air or time-based blade switching mechanism |

🔍 Blade Condition: Is your cutting edge still sharp?

A dull blade is the most common cause of poor cuts. Bubble wrap is deceptively difficult to cut cleanly, especially at high speed. If your blade hasn’t been changed recently, that’s your first suspect.

What to check:

- Look at the blade under a light. Is the edge shiny? That means it’s dull.

- Are there small plastic residues or adhesive buildup? That’s adding friction.

- Is the blade material suitable for plastic or foam materials?

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we use high-hardness alloy blades in our Bubble wrap cutting machines and Protective Foam Cutting Machines to reduce blade wear. These blades last longer and can handle continuous cuts without overheating.

If you’re using a manual or lower-end model without automatic blade height adjustment, wear will be uneven—resulting in jagged cuts over time.

🎯 Roller Misalignment: Are your rollers guiding the material evenly?

If your rollers are even slightly misaligned, your bubble wrap may shift during feeding, causing the blade to cut off-center or tear the material. This is common in cheaper cutting setups.

Key things to verify:

- Pressure: Is the nip roller applying uniform pressure across the web width?

- Alignment: Are the rollers perfectly parallel, or is one side higher?

- Material feed: Is your bubble wrap feeding in a straight line, or drifting?

Misalignment usually occurs after long use or during transport. We designed our webbing ribbon cutting machines2 with micro-adjustable tension rollers to avoid this.

A misaligned roller setup could also be overstretching the bubble wrap—changing its tension right before cutting. Always test the feed rate and roller pressure during setup.

⚡ Static Buildup: Is static interfering with precision?

When cutting bubble wrap, static buildup can attract dust or cause the film to cling unpredictably—especially in dry environments or fast-running machines.

This static can make the material "jump" or shift slightly right before the blade drops, causing a jagged or misaligned edge.

What you can do:

- Use an antistatic bar or ionizer to neutralize charge near the cutting area.

- Increase ambient humidity to reduce static.

- Ground your machine frame and use antistatic mats.

Some of our high-speed trademark cutting machines come with optional static eliminators for this exact reason.

If you’re running your machine in winter or in a dry room with lots of synthetic materials, static will be a consistent issue. Don’t overlook it—it causes more cutting errors than people realize.

Conclusion

Troubleshooting starts with isolating the cause—blade, roller, or static—and fixing it at the root.

🧠 Industry Insight: Diagnosing Ragged Cuts on Bubble Wrap—Before It Costs You

From over two decades of factory visits, the most common (and costly) production error I see in bubble wrap lines isn’t overheating or blade wear—it’s improper diagnosis. Teams replace blades when the issue is static, or adjust rollers when the real problem is uneven blade heat. The result? Hours lost, film wasted, and workers frustrated.

Here’s the trick: use failure patterns to guide your fix. For instance, if cuts degrade during long runs but start clean, that’s likely thermal distortion—not dull blades. If film skews sideways before cutting, suspect roller tension or misalignment, not blade sharpness.

Top-tier machines like those from HAOXINHE integrate feedback sensors, roller alignment guides, and optional ion bars for static. These aren’t luxuries—they’re preventive tools. One client cut defect rates by 30% in a week just by re-aligning feed rollers and upgrading to coated blades with better heat dispersion.

Treat cutting quality like an output symptom—not a standalone problem. Fix the source, and the edge will follow.

Uneven cuts on bubble wrap usually come down to three key factors: dull blades, misaligned rollers, or static electricity. At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we design cutting machines with precision components to avoid all three issues. Our Bubble wrap cutting machines and Protective Foam Cutting Machines are built for industrial use, customizable, and optimized for long-term performance. If you’re dealing with cutting issues, upgrading to a machine with precision rollers, static elimination, and high-speed alloy blades can solve your problem—and save your team hours each week.

Need help choosing the right model? Visit hxcuttingmachine.com or contact me at cherryhaoxinhesz@gmail.com.