Can automated cutters reduce labor time for belt leather fabrication?

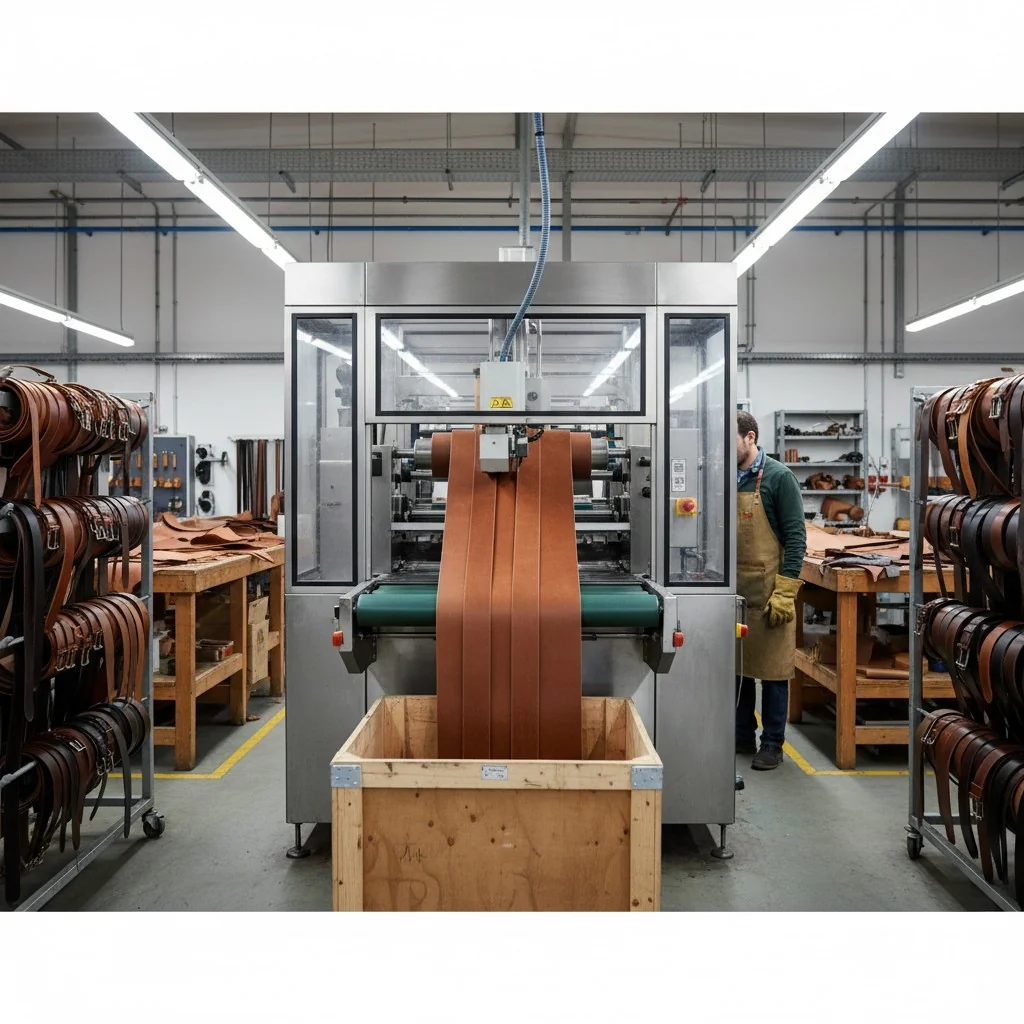

Leather belt manufacturers often lose production hours to slow hand-cutting and poor edge consistency that result in high defect rates.

Yes—automated cutters significantly reduce labor time in leather belt fabrication by delivering fast, precise cuts at scale, with reduced waste and minimal manual handling.

1: Automated cutters are revolutionizing leather belt manufacturing by slashing labor time and maximizing production efficiency.

2: CNC technology enables precise, repeatable cuts—even for complex designs—far beyond manual capabilities.

3: These machines support continuous, fatigue-free operation, drastically increasing throughput.

4: They also minimize the setup and manual effort typically required in traditional cutting.

5: For belt leather producers, automated cutters are key to scaling operations with consistent quality and lower labor costs.

I’ve worked with leather accessory producers in North America and Europe, and the common pain point is always the same: time-consuming cutting. Whether it’s traditional tooling or semi-automatic machines, they simply can’t meet the speed or consistency required for wholesale belt production. That’s where our automated machines come in.

Can automated cutters reduce labor time for belt leather fabrication?

Hand cutting belts is not just slow—it causes inconsistent widths, uneven edges, and higher material waste.

Automated leather cutters save up to 60% in labor time by producing repeatable, uniform cuts, improving production speed and reducing rework.

Traditional leatherwork depends on skilled labor, but that model doesn’t scale. A worker cutting 100 belts a day by hand might take 6–8 hours. Our webbing tape cutting machine, on the other hand, can produce 1000+ belt blanks per hour with ±0.1mm accuracy.

For one client who switched to our hot and cold cutting machine, their labor costs dropped by 40%, and their production output doubled in the first 3 months. Here’s what changed:

Manual vs Automated Cutting – Labor Impact

| Task | Manual (per 100 belts) | Automated (per 100 belts) |

|---|---|---|

| Measuring and marking | 1 hour | 0 minutes (digital input) |

| Cutting | 2 hours | 5 minutes |

| Edge inspection/rework | 1 hour | 10 minutes |

| Total Time | 4 hours | 15 minutes |

These numbers show why large leather factories are switching to automation. With our rotary bevel cutting machine or round shape cutting machine, clients also cut different tip shapes or round holes at high speed—no retooling required.

Use Cases in Leather Goods Production

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we serve manufacturers producing:

- Leather belts

- Bag straps

- Dog collars

- Fashion accessories

They all benefit from consistent cut width, fast changeovers, and programmable lengths.

Machines like our different shapes cutting machine also allow multiple belt end shapes (rounded, pointed, flat) without manual switching—great for variety-packed SKUs.

What blade types ensure clean leather edges without scorching?

Leather is sensitive to heat and blade pressure—wrong tools can scorch edges, deform grain, or leave ragged cuts that ruin product quality.

Cold blades with straight or rotary edges are ideal for leather; for heat cutting, use temperature-controlled hot knives with Teflon coating to avoid scorching.

Leather behaves differently from synthetics. It burns easily and frays when over-stretched. That’s why blade selection matters just as much as machine speed.

Blade Options for Leather Cutting

| Blade Type | Best For | Cautions |

|---|---|---|

| Cold Steel Blade | Clean cuts on natural leather | Needs regular sharpening |

| Rotary Blade | Continuous cuts, round shapes | Avoid if leather is too thick |

| Hot Knife (Teflon) | Synthetic or waxed leather | Must control temperature closely |

| Beveled Edge Knife | Decorative tip shapes | Use with reinforced blade guides |

Our hot and cold cutting machines are built for both types. You can switch blade modules based on material:

- For natural leather belts, we use cold steel blades with adjustable pressure.

- For PU leather, PVC trims, or waxed straps, we offer hot knife attachments with precision temperature control.

Preventing Scorching and Fraying

To ensure clean leather edges:

1. Use Low-Speed Passes

High-speed blade movement causes friction heat. Our cutters allow you to slow the feed without affecting edge quality.

2. Install Cooling Fans or Guards

This is optional but useful in tropical workshops. Some clients install airflow nozzles to cool freshly cut edges instantly.

3. Match Blade to Leather Type

Vegetable-tanned leather cuts better cold. Chrome-tanned or synthetic blends often benefit from a low-heat pass.

We advise clients to test on sample pieces. All Haoxinhe machines support test mode, where you can simulate full cuts before starting mass production.

Adjustable Settings for Edge Quality

Our computer tube cutting machine and wire cutting and stripping machine include:

- Pressure adjustment controls

- Blade sharpness detection

- Auto-retract safety mode

- Programmable delay to reduce edge drag

These are essential when you’re cutting premium leather goods sold at a high margin—especially for private label buyers like Mark from Canada, who rebrands our OEM output under his local line.

Conclusion

Automated leather cutting saves time, improves cut quality, and enables consistent results for scalable belt manufacturing.

🧠 Industry Insight: Why Manual Leather Cutting Is a Scaling Trap

In my experience consulting for leather goods factories, especially those scaling for export markets, manual belt cutting is where most production plans fall apart. It seems efficient at small scale—but once daily output crosses 500+ units, labor costs, defect rates, and quality inconsistencies skyrocket. Skilled artisans simply can’t maintain millimeter-precise cuts across thousands of belts.

That’s why automated belt cutters aren’t just labor-saving—they’re profit-saving. For example, one client in Italy cut labor by 50% and eliminated edge rework entirely within two weeks of switching to our programmable rotary cutter. The consistency was so sharp, their QC team shortened inspection cycles by 30%.

The key is flexibility. With the right setup, you can cut standard belt blanks, rounded tips, and punched holes—all without changing tooling. That matters when your SKU list includes dozens of lengths, colors, and shapes.

If your leather factory is still hand-cutting, you’re likely underestimating your hidden costs: blade waste, off-spec rejects, and overworked staff. In today’s fast-turn retail cycles, automation isn’t just modern—it’s mandatory.

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we manufacture automatic cutting machines tailored for leather strap and belt production. With hot and cold blade options, precision controls, and customizable shapes, our cutters reduce labor hours and prevent material damage—making them ideal for fashion accessory factories scaling output.