Are automatic paper cutters improving throughput in print-on-demand plants?

Print-on-demand factories are losing money every hour to slow, manual cutting processes that create delays and pile up rework.

Yes—automatic paper cutters significantly increase throughput in print-on-demand plants by reducing downtime, improving cut precision, and eliminating bottlenecks in finishing operations.

1: Automatic paper cutters are transforming print-on-demand (POD) operations by dramatically increasing processing speed and precision.

2: These machines outperform manual cutting, reducing errors and enhancing accuracy in every print cycle.

3: By lowering labor costs and streamlining workflow, POD plants can handle higher order volumes with faster turnaround.

4: Automation enables consistent quality, especially for bulk and custom printing jobs.

5: For POD businesses aiming to scale, automatic paper cutters are essential tools for boosting efficiency and profitability.

If you’re operating a digital printing line or managing a POD facility, paper cutting is probably where you’re bleeding time. I’ve helped dozens of clients overhaul their finishing departments with high-speed, programmable cutting machines that transform their workflow.

Are automatic paper cutters improving throughput in print-on-demand plants?

Manual paper trimming leads to bottlenecks, misaligned cuts, and wasted output—all of which slow down order fulfillment.

Automatic paper cutters streamline the finishing stage, enabling faster, more accurate processing of high-volume jobs and custom sizes in print-on-demand facilities.

Print-on-demand (POD) is all about speed and flexibility. Customers expect short-run books, flyers, or custom labels printed and shipped within 24–48 hours. But slow or inconsistent paper cutting ruins that timeline.

In my conversations with POD plant managers, most admit that cutting is their slowest link. That’s where automatic machines change everything. Machines like our high-speed trademark cutting machine and different shapes cutting machine can process hundreds of sheets per minute, cut into multiple formats, and reduce operator dependency.

Benefits of Automation in POD Finishing

| Challenge Without Automation | Solved by Automatic Paper Cutter |

|---|---|

| Long job changeover time | Programmable size memory |

| Misaligned manual cuts | Laser alignment + servo precision |

| Operator fatigue | Fully automated push/feed system |

| Backlogs in finishing queue | Continuous stack cutting capability |

| Inconsistent output sizes | ±0.1mm tolerance with sensor calibration |

Even small POD businesses that installed our webbing ribbon cutting machine for cutting printed tags and ticket rolls saw a 3x increase in throughput within weeks.

Integration with Print-and-Pack Lines

The beauty of automatic cutters like our computer tube cutting machine is their ability to sync with upstream and downstream devices. You can align them with your digital press stackers, barcode scanners, or label printers.

For example, one European client now uses:

- A digital press feeding into a stacking conveyor

- Then into our rotary bevel cutting machine

- Output goes straight to a boxing robot for shipment

No human touch needed. That’s 24/7 POD at scale.

What safety interlocks do industrial paper cutters need?

High-speed blades moving through thick paper stacks can cause serious accidents—without safety systems, these machines become dangerous liabilities.

Industrial paper cutters must include interlocks like two-hand operation, safety light curtains, emergency stop systems, and blade guards to protect operators.

Safety is not optional. In factories like ours, we prioritize this not just to comply with regulations, but to make sure our clients’ workers stay safe—even under pressure and long shifts.

Mandatory Safety Features for Compliance

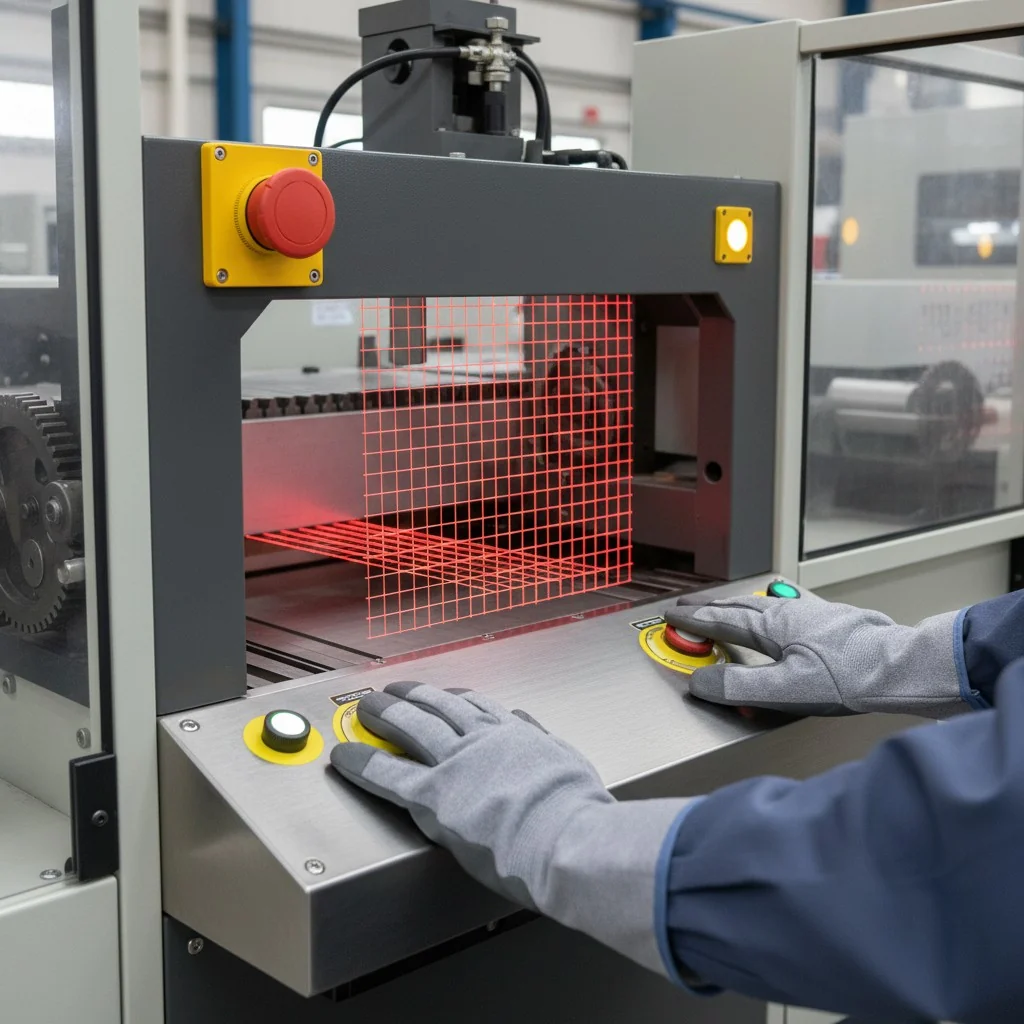

1. Two-Hand Operation

The machine should only activate cutting if both hands are used simultaneously. This ensures no hand is near the blade when the cut begins.

2. Light Curtains or Laser Safety Beams

These stop the blade immediately if anything enters the cutting area. We build this into our automatic punching cutting machine and round shape cutting machine for full-stack safety compliance.

3. Emergency Stop (E-Stop)

Operators must have large, visible emergency buttons that cut off power instantly. Our clients in North America require these per OSHA standards.

4. Blade Guarding Mechanisms

Clear or metal guards should automatically cover the blade when idle. Our protective foam cutting machine also uses sensor-triggered guards when a hand gets close.

5. Auto Shut-Off on Jam or Malfunction

Sensors should detect jams or overloads and stop the machine to prevent damage or injury. These are standard in all machines we export to the EU and Singapore.

International Safety Certifications You Should Demand

| Certification | Region | What It Covers |

|---|---|---|

| CE | Europe | Electrical safety, mechanical interlocks |

| OSHA | USA | Worker safety standards, blade operations |

| ISO 12100 | Global | Machine risk analysis and design safety |

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we don’t cut corners (pun intended) on safety. We’ve had German inspectors audit our facilities, and we always provide verified compliance documentation—no fakes, no delays.

Conclusion

Automatic paper cutters improve speed, safety, and precision—making them critical for any modern print-on-demand operation.

🧠 Industry Insight: Cutting Time Is Cutting Cost in POD

From my years advising POD operations, I’ve seen a common pattern: most print-on-demand plants treat finishing as an afterthought—until delays start costing thousands in rework and refunds. Manual paper cutting is usually the weakest link. It’s inconsistent, fatiguing, and prone to alignment errors, especially with custom jobs or varied formats.

What’s changed recently is the level of automation now accessible to even small-scale printers. High-speed cutters equipped with servo motors and touch-screen programming eliminate the need for manual measurements or trial runs. In one case, a client cut job changeover time from 15 minutes to under 2 by simply upgrading to a programmable cutter with preset memory banks.

Another game-changer? Seamless line integration. Today’s top machines aren’t standalone—they sync with digital presses, barcode readers, and packing lines. I’ve watched clients go from bottlenecks to fully automated 24/7 output with zero operator intervention between print and pack.

The big takeaway: if your POD plant is still relying on hand-fed guillotines or semi-auto trimmers, you’re not just slower—you’re losing competitive edge. In a market that rewards fast fulfillment, precision automation isn’t a luxury. It’s survival.

Suzhou Haoxinhe Electrical Equipment Co., Ltd. supplies fully automated, safety-certified paper cutting machines that help POD factories boost throughput and meet tight turnaround demands without compromising operator safety. Our equipment supports large-volume jobs, unique shapes, and complex cuts with zero tolerance for error.