How are wire stripping machines1 revolutionizing electric vehicle production?

Electric vehicle manufacturers are struggling with complex, high-voltage wiring systems—slow, manual stripping creates a serious production bottleneck.

Wire stripping machines are transforming EV production by delivering faster, safer, and more consistent cable preparation2, especially for thick and high-voltage cables.

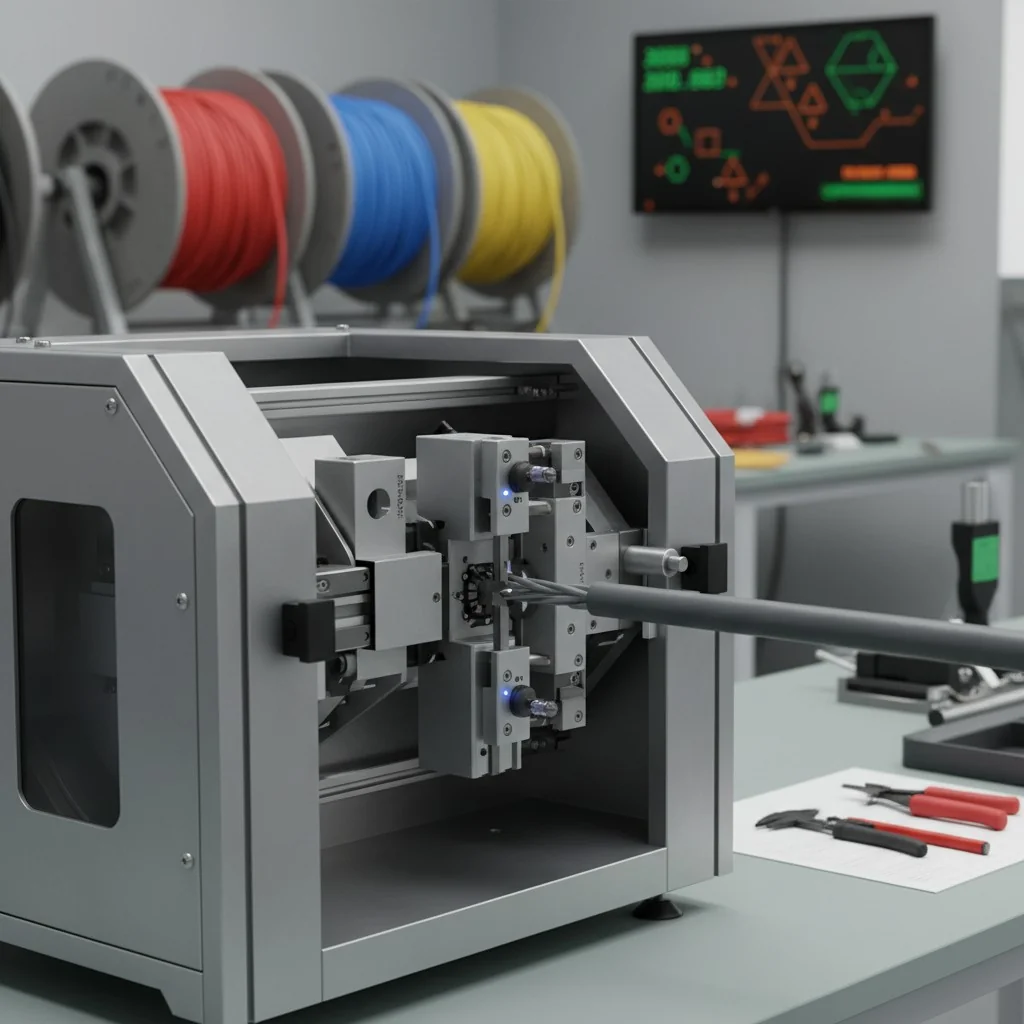

1: Wire stripping machines are revolutionizing electric vehicle (EV) production by automating the cutting and stripping of thick, high-voltage cables.

2: These machines deliver faster processing, consistent precision, and reduced labor costs—eliminating the delays and risks of manual methods.

3: Ideal for EV batteries, motors, and inverters, they ensure safe, damage-free cable prep at scale.

4: EV manufacturers now integrate advanced wire stripping solutions directly into automated lines for unmatched efficiency.

5: As demand for high-voltage EV cables grows, automated strippers have become essential for quality, compliance, and production speed.

In this blog, I’ll show you exactly how automatic wire stripping machines1 are becoming essential in EV manufacturing. And if you’re in the high-voltage cable business, I’ll also walk you through what to look for when choosing a reliable stripper.

How are wire stripping machines1 revolutionizing electric vehicle production3?

EV manufacturers are under pressure to scale fast, but traditional wire stripping methods simply can’t keep up.

Automated wire stripping machines1 enable mass-scale EV production by reducing manual labor, minimizing errors, and speeding up output—especially for high-voltage cables.

Electric vehicles (EVs) rely on thick, multi-layered, high-voltage cables to connect batteries, motors, sensors, and inverters. Unlike small appliances, these cables require precise cutting and stripping to avoid safety hazards and electrical failures. Manual stripping is not only slow, but it often leads to inconsistent results and damaged insulation.

That’s where specialized wire stripping machines1 come in. In my factory, Suzhou Haoxinhe Electrical Equipment Co., Ltd., we design and build wire cutting and stripping machines specifically for complex industrial applications like EVs. Our equipment ensures exact cutting depth, angle, and speed—every single time.

Why EV Manufacturers Are Making the Switch

| Traditional Stripping | Automatic Machine Stripping |

|---|---|

| Manual errors | Consistent quality |

| Slow speed | 3–5x faster output |

| High labor cost | Automated operation |

| Inconsistent lengths | Programmed precision |

| Risk of insulation damage | Controlled blade pressure |

In particular, our computer tube cutting machine and wire cutting and stripping machine are now used by several EV cable manufacturers in Europe. They’re especially useful for thick, reinforced cables and delicate multi-core wires.

Integration with Automation Lines

Many EV factories are now integrating our machines directly into their production lines. That includes rotary bevel cutting machines and metal pipe cutting and beveling machines—perfect for battery modules and electronic enclosures.

When your goal is to scale EV output to meet demand, the small steps matter. Automated wire stripping saves hours per production shift and reduces defect rates by up to 70%.

What to check in wire strippers for high-voltage cable manufacturing?

High-voltage cable production needs machines that are not just fast—but also ultra-precise and reliable over long-term operation.

When selecting a wire stripper for high-voltage cables, check the blade control, insulation detection, compatibility with thick cables, and certification for safety standards.

If you’re producing high-voltage cables for EVs, solar panels, or industrial power systems, you can’t use just any wire stripping machine. Here are the most critical specs and features I always recommend checking when advising a new client.

Key Factors to Consider

1. Precision Blade Control

High-voltage cables often have multiple insulation layers. If the blade is too deep, it damages the inner conductor. If it’s too shallow, it leaves insulation behind.

Look for machines that offer:

- Adjustable blade depth

- Programmable stripping length

- Servo motor control for cutting heads

Our automatic punching cutting machine includes these features as standard.

2. Support for Cable Size

Some cables are as thick as 35mm or more in diameter. Standard machines won’t cut it—literally.

Choose models like our wire cutting and stripping machine, which supports thick cables used in EV battery packs.

| Cable Type | Recommended Machine |

|---|---|

| 10–25mm single-core | Wire cutting and stripping machine |

| Multi-core HV cables | Computer tube cutting machine with rotary head |

| Shielded cables | Precision cutting machine with insulation peel |

3. Non-Destructive Stripping

The most advanced machines use laser sensors or visual detection to prevent damage to internal wires. This is crucial for high-voltage applications where a small nick can lead to major failures.

4. Certifications and Compliance

This is non-negotiable. Always look for CE, ISO, and relevant electrical safety certifications. Many resellers overseas fake certificates, which can land you in legal trouble or recalls.

In my factory, we handle these documents directly and provide verified certifications that pass European inspections. We’ve had clients from Germany and Canada audit our process on-site.

5. Ease of Integration

Some buyers forget about this: the machine needs to fit into your production line. That’s why we design modular units for EV cable producers, with options to integrate:

- Bubble wrap cutting machine for insulation materials

- PVC edge banding cutting machine for cable coverings

- Protective foam cutting machine for packaging lines

These allow smooth inline processing from cable core prep to final packing.

Conclusion

Wire stripping machines are no longer optional—they are the backbone of modern EV cable manufacturing.

Insights

Suzhou Haoxinhe Electrical Equipment Co., Ltd. is helping EV factories worldwide by delivering cutting-edge wire stripping and tube cutting machines designed for precision, speed, and reliability. From Canada to Germany, our clients trust us to streamline their high-voltage cable production with certified equipment that’s ready for global integration.

In my two decades working with industrial automation and cable processing machinery, one thing is clear: the biggest hidden cost in EV manufacturing isn’t batteries—it’s time lost in manual operations like wire stripping. High-voltage EV cables aren’t just thick—they’re layered, shielded, and unforgiving. A single bad strip can mean an electrical failure down the line.

Ten years ago, even top-tier factories were using semi-automated solutions with high scrap rates. Today, we’re seeing fully integrated, servo-driven stripping systems that achieve sub-millimeter accuracy at 5x the throughput. The ROI on these machines is often under six months.

What surprises most newcomers to the EV sector is how critical wire preparation is. It’s not "just a step"—it’s the foundation for the entire vehicle’s electrical reliability. That’s why leading OEMs now audit suppliers specifically for this capability. Machines like our rotary bevel or precision insulation peelers are no longer "nice to have"—they’re mandatory for quality control, especially when dealing with international safety standards4 like IEC or UL.

If you’re scaling EV production and still using manual wire prep, you’re burning capital. The transition to automation isn’t just a tech upgrade—it’s a strategic imperative.

Explore how wire stripping machines enhance efficiency and safety in EV manufacturing. ↩ ↩ ↩ ↩ ↩

Find out why proper cable preparation is crucial for the reliability of electric vehicles. ↩

Learn about the latest advancements in electric vehicle production and their impact on the industry. ↩

Get informed about essential safety standards that ensure compliance in EV production. ↩