Why Are Digital Label Cutting Machines Booming in Industrial Packaging?

The demand for faster, smarter, and more precise label production has exploded. Industrial packaging can’t keep up without automation.

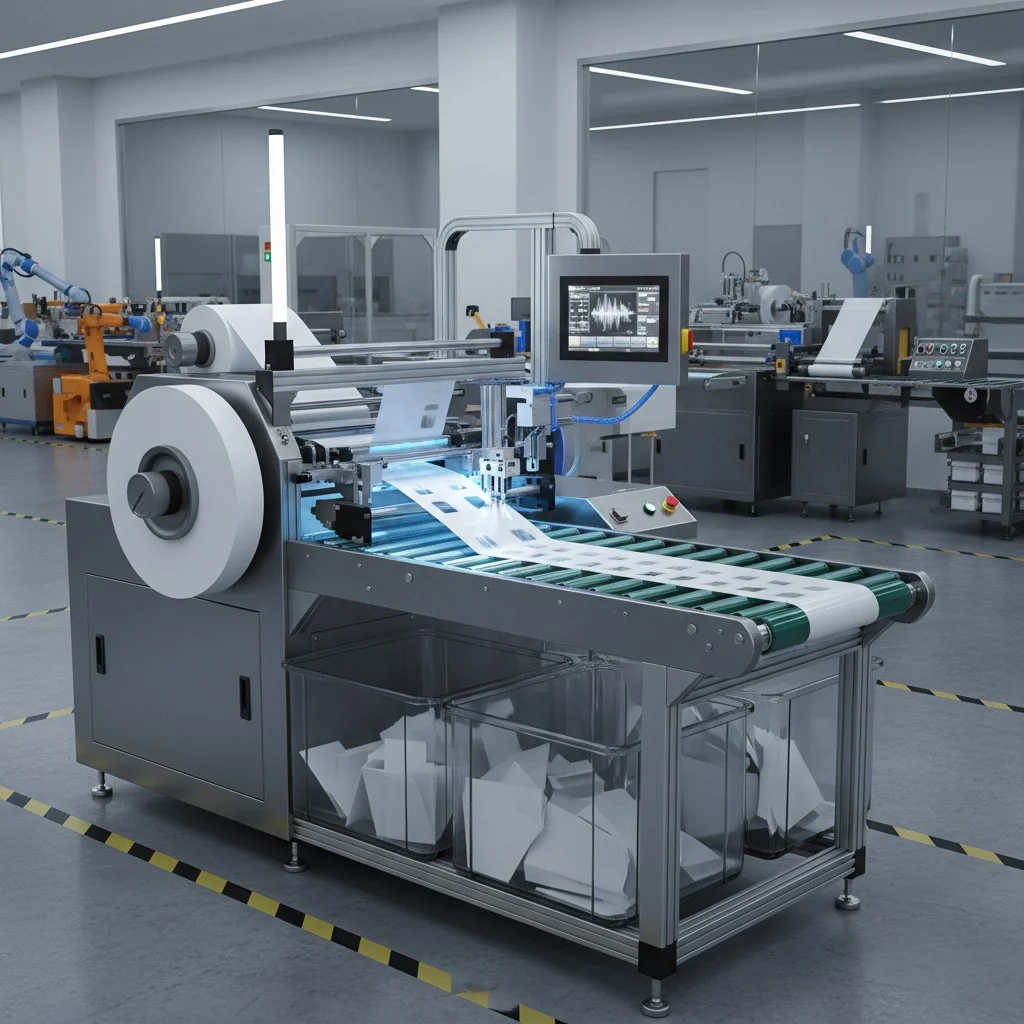

Digital label cutting machines1 are booming because they offer faster turnaround, precision, and adaptability that traditional die-cutting cannot match in today’s high-mix, low-volume production.

1: Digital label cutting machines1 are revolutionizing industrial packaging with unmatched flexibility and precision.

2: They eliminate the need for costly rotary dies2, making custom and short-run label production faster and more cost-effective.

3: Businesses benefit from reduced material waste3, lower labor costs, and minimal equipment overhead.

4: Advanced automation enables quicker turnaround times, boosting overall productivity.

5: These systems also support intricate, high-quality designs, enhancing brand presentation and market appeal.

With smart factories scaling up and customer orders becoming more customized, manufacturers can’t afford slow, inflexible cutting systems. Let me explain why this shift is happening—and what’s coming in 2025.

Why Are Digital Label Cutting Machines So Popular in Industrial Packaging?

Traditional methods are too slow. Manual die cuts take too long to set up and switch out.

Digital label cutting machines1 eliminate dies, reduce waste, and make on-demand production easier for industrial packaging businesses.

Speed and Flexibility Are Crucial

Most factories I work with now prioritize short runs and fast changeovers. Old die-cutters require molds, tools, and long downtimes for adjustments. This doesn’t work anymore—especially for companies like Mark in Canada, who need fast lead times from Chinese suppliers.

With digital label cutting, I can fulfill multiple SKUs in one day. The cutting path is controlled by software, so I just upload the design and press start. Whether it’s 100 labels or 10,000, the machine doesn’t care.

Zero Setup Time Means Higher Efficiency

This is especially valuable for packaging suppliers who serve multiple product lines. No tooling or dies means:

| Traditional Die Cutting | Digital Label Cutting Machine |

|---|---|

| Long setup time | Zero setup |

| Requires physical dies | Fully digital |

| Limited to one shape per die | Unlimited custom shapes per job |

| High cost for short runs | Cost-effective for all batch sizes |

Factories like Suzhou Haoxinhe Electrical Equipment Co., Ltd. have responded to this shift by designing hot and cold cutting machines, rotary bevel cutters, and computerized label cutters with real-time adjustments. That’s a game-changer for anyone in the industrial packaging chain.

Consistent Cutting Quality Every Time

In industries like chemicals or HVAC where label misplacement can lead to regulatory fines, accuracy is not optional. Digital cutters don’t degrade like physical dies. The precision is repeatable and programmable.

What Can Smart Label Cutters Deliver in 2025?

Factories are going smart. Label cutting machines are evolving too.

In 2025, smart label cutters will feature real-time error correction, AI optimization, IoT connectivity, and seamless integration into digital production lines.

AI + IoT = Predictive Labeling

More companies are investing in connected production. In 2025, smart label cutters will connect directly to ERP and MES systems. Orders can be triggered automatically based on inventory, and machine settings will adjust in real-time for each order.

Label cutting will no longer be an isolated process. It will be a fully integrated part of the smart factory.

What This Means for Businesses Like Mark’s:

- No more manual inputs

- Faster order-to-delivery cycles

- Fewer human errors

- Real-time machine health tracking

Automatic Adjustment and Self-Optimization

Many of the new webbing tape cutting machines and PVC edge banding cutting machines now include sensors that check cutting accuracy as they work. In 2025, these systems will go further—they will fix issues on their own.

Think of it like a car with adaptive cruise control. If materials shift or expand due to humidity, the machine compensates mid-job. That protects quality without stopping production.

Lower Waste and Higher ROI

Sustainability is becoming mandatory in Europe and North America. In 2025, smart label cutters will help manufacturers meet stricter regulations by:

- Cutting only what’s needed

- Reducing edge waste

- Using digital layouts to minimize gaps between labels

With features like automatic nesting and material tracking, companies can report their sustainability impact to clients and regulators confidently.

| Feature | Available Now | In 2025 |

|---|---|---|

| Digital shape library | ✅ | ✅ |

| IoT connectivity | ❌ | ✅ |

| Real-time self-correction | ❌ | ✅ |

| Predictive maintenance | ❌ | ✅ |

| ERP integration | ❌ | ✅ |

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we’re already seeing demand for bubble wrap cutting machines, protective foam cutters, and automatic punching cutters that can talk to warehouse systems. 2025 will only make that more standard.

Conclusion

Digital label cutting machines1 are no longer a luxury—they are becoming a necessity in modern industrial packaging workflows.

Insights

By investing in digital and smart label cutting machines from Suzhou Haoxinhe Electrical Equipment Co., Ltd., B2B buyers like Mark in Canada can solve their biggest pain points: slow lead times, inconsistent quality, and communication gaps. Our customizable cutting equipment—from round shape cutting machines to computer tube cutting systems—aligns perfectly with the needs of modern, high-mix manufacturing environments. As 2025 approaches, companies that adopt smarter, integrated label cutting technologies will stay ahead of their competitors and be better positioned to meet growing sustainability and traceability demands.

In my two decades advising manufacturers and packaging suppliers, I’ve seen few transitions as decisive as the current boom in digital label cutting machines. This isn’t just about faster machines—it’s about survival in a post-COVID, demand-fragmented economy.

Here’s the inside scoop: big brands now expect near-instant SKU switching, micro-runs, and sustainability reporting as a baseline. Traditional die-cutting can’t keep up. That’s why the real winners are the suppliers who moved early into smart cutting ecosystems—those that integrate cutting machines with ERP, MES, and cloud-based monitoring.

One of our partners in Suzhou mentioned that what used to be a “cutting station” is now a full-stack digital node in their Industry 4.0 setup. Machines like edge banding cutters and PVC tube slicers now self-optimize, predict wear, and auto-adjust mid-job based on temperature or material variance. That’s not future tech—it’s happening now.

If you’re still treating label cutting as a standalone process, you’re not just slow—you’re invisible to modern procurement platforms. The smart money? It’s on vendors who offer not just hardware, but data-integrated cutting solutions4 with real-time adaptability.

Explore how digital label cutting machines are transforming the packaging industry with speed and precision. ↩ ↩ ↩ ↩

Understand the limitations of rotary dies and how digital solutions can overcome them. ↩

Explore strategies for minimizing waste in label production through digital cutting technologies. ↩

Explore how data integration can enhance the efficiency and adaptability of cutting solutions. ↩