What are the safety precautions when using a webbing punch hole machine1?

Accidents in the factory are expensive—not just financially, but also for team morale and business continuity.

To operate a webbing punch hole machine1 safely, follow lockout-tagout procedures, wear proper PPE2, install emergency stops3, and train all staff on safe machine operation.

1: Always wear essential PPE2—safety glasses, gloves, and ear protection—to guard against debris and sharp edges.

2: Secure and properly align webbing before activating the punch to ensure accurate and safe operation.

3: Never place hands near the punching area while the machine is active to prevent injuries.

4: Avoid overloading the machine to maintain mechanical integrity and operator safety.

5: Perform routine inspections4 to detect wear, damage, or malfunction early.

Following these safety practices is critical for injury prevention and maintaining long-term machine reliability.

A few years ago, one of our new operators misunderstood a reset button on a Protective Foam Cutting Machine. The press cycle restarted while he was clearing the material. He wasn’t injured, thankfully, but it was a close call. Since then, we’ve re-trained all operators and upgraded our safety interlock systems on every new automatic punching cutting machine we produce at Suzhou Haoxinhe Electrical Equipment Co., Ltd.

How to avoid injuries while operating a high-speed webbing punch press?

High-speed presses punch fast and hard—if your hand is in the wrong place, there’s no second chance.

Avoid injuries by using two-hand start controls5, light curtains, safety guards, and clear training for every punch press operator.

Understand the risks

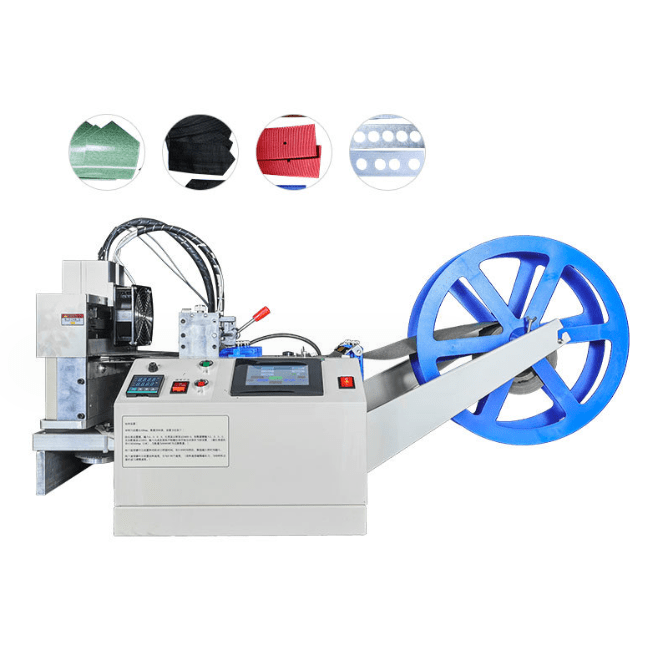

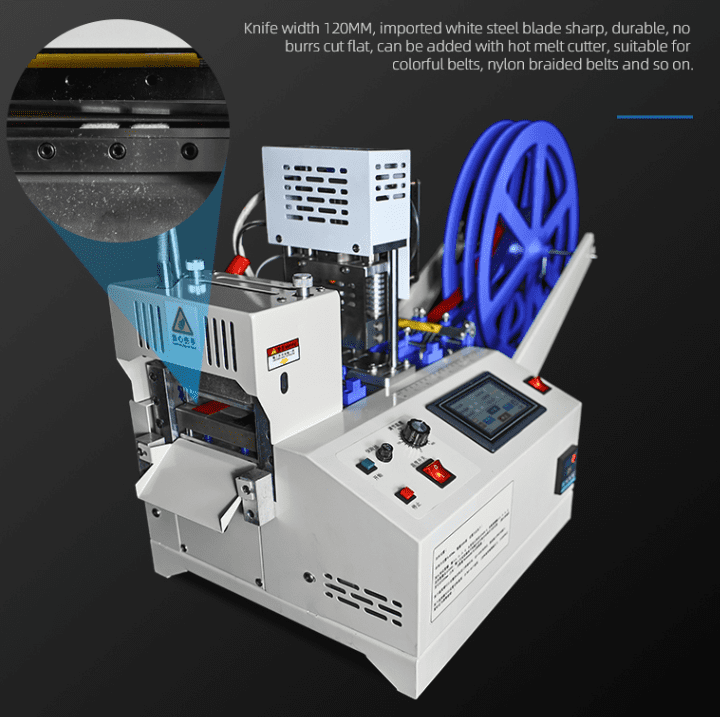

High-speed webbing punch presses—especially our rotary bevel cutting machines and webbing tape cutting machines—can punch hundreds of cycles per minute. Without proper safety systems, that speed becomes dangerous. The main risks include:

- Hand or finger injuries

- Unexpected activation

- Slipping or tripping on loose webbing

- Electric shock from poorly grounded components

What safety features should the machine have?

| Safety Feature | Function | Required on Haoxinhe Machines |

|---|---|---|

| Two-Hand Start System | Prevents accidental punch activation | ✅ |

| Emergency Stop Button | Immediately halts operation during any emergency | ✅ |

| Safety Light Curtain | Stops the machine if an object enters punch zone | ✅ |

| Interlock Guards | Prevent operation if doors or shields are open | ✅ |

| Non-slip Floor Pads | Prevent operator falls | Optional |

| Grounded Power Supply | Avoids shock and electrical fires | ✅ |

All our models—from the PVC Edge Banding Cutting Machine to the Bubble Wrap Cutting Machine—can be optionally fitted with enhanced safety kits, depending on the client’s factory layout and operator experience.

Safety checklist before each shift

- ✅ Check the emergency stop function.

- ✅ Inspect power cables and confirm grounding.

- ✅ Ensure guards and covers are secured in place.

- ✅ Test two-hand start mechanism.

- ✅ Clear loose webbing or debris from work area.

- ✅ Verify operator PPE2: gloves, goggles, non-slip shoes.

- ✅ Review machine logbook for recent issues.

By making this checklist part of the daily routine, you prevent most common injuries.

Train your staff—don’t assume experience equals safety

Many of our clients assume older operators “just know what to do.” But training needs to be updated every time:

- A new model (like the high-speed trademark cutting machine) is introduced

- A new operator joins the team

- A machine gets upgraded with new safety tech

At Suzhou Haoxinhe, we offer free safety training materials and remote video demos for all our OEM clients—including translated versions for international buyers like Mark from Canada. We believe a safe factory is a productive one.

Conclusion

Machine speed means nothing without safety. Always train your team and choose machines with built-in protection systems.

Insights

In 20+ years working with factories, I’ve seen the same mistake repeat: managers focus on output first, safety second—until the first accident happens. The truth is, safety isn’t just compliance, it’s cost control. Every injury means downtime, insurance claims, and operator turnover.

One of the most effective upgrades we recommend is integrated safety automation6. Two-hand start systems and light curtains are good, but the real gains come from pairing them with smart diagnostics7. Modern machines like those from Suzhou Haoxinhe can log every emergency stop or interlock trigger. Reviewing those logs monthly reveals risky operator behavior—like repeated guard bypasses—before accidents occur.

Another overlooked point: PPE2 is the last line of defense, not the first. If your operators rely on gloves instead of well-calibrated guards, you’re putting people and equipment at risk. In our client audits, factories that enforced a strict “machine first, PPE2 second” safety culture had 70% fewer incidents.

Bottom line: safety precautions should be built into your workflow, not treated as optional add-ons.

Safe operations are smart operations. At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we embed industrial-grade safety features in every webbing ribbon cutting machine, automatic punching cutting machine, and rotary bevel cutting machine we produce. This protects both your operators and your business, helping global clients stay compliant and accident-free.

Explore this link to understand essential safety features that ensure safe operation of webbing punch hole machines. ↩ ↩

Learn why proper PPE is crucial for protecting operators from injuries while using machinery. ↩ ↩ ↩ ↩ ↩

Discover how emergency stop systems can prevent accidents and save lives in industrial settings. ↩

Learn about the key components of routine inspections that help maintain machine safety and reliability. ↩

Find out how two-hand start controls can significantly reduce the risk of accidental machine activation. ↩

Learn how integrated safety automation can enhance safety and efficiency in machine operations. ↩

Explore how smart diagnostics can help identify risky behaviors and prevent accidents in the workplace. ↩