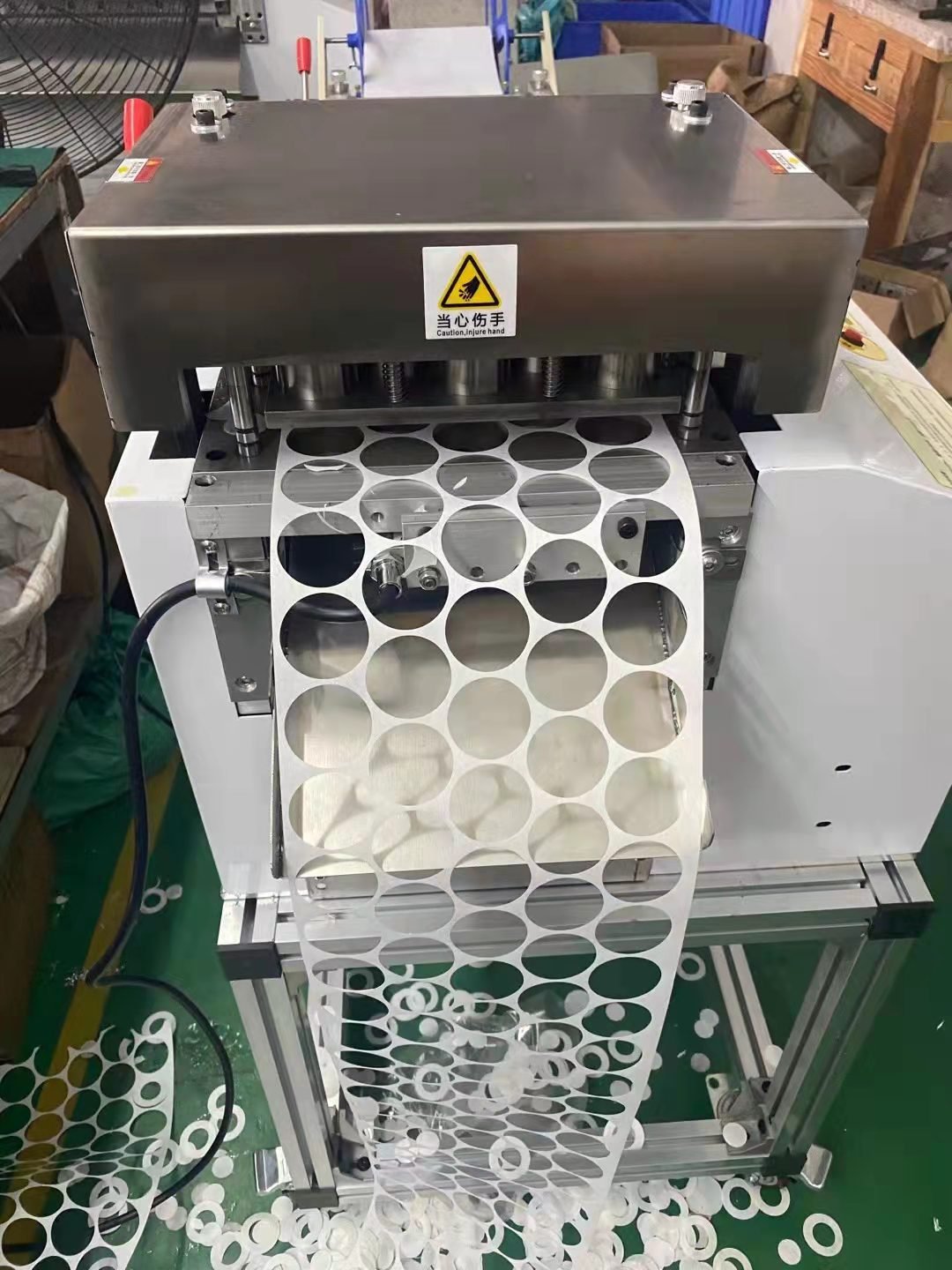

How to Maintain a Webbing Punch Hole Machine for Long-Term Use?

A neglected machine will cost you more in downtime than the price of regular care.

Maintain a webbing punch hole machine1 by lubricating moving parts, inspecting dies, cleaning daily, and scheduling preventive maintenance every 3–6 months.

- Regular maintenance is key to extending the lifespan of a webbing punch hole machine1.

- Focus on routine cleaning, especially the die and punch, to prevent debris buildup.

- Apply proper lubrication to all moving parts to ensure smooth operation.

- Replace worn or damaged components promptly to avoid production issues.

- Consistent operator training and periodic calibration help maintain accuracy, efficiency, and long-term performance.

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we’ve seen clients extend the life of their automatic punching cutting machines and webbing tape cutting machines for over 10 years with the right care. When buyers like Mark from Canada ask about lifespan, I tell them it’s not just about the build—it’s about consistent upkeep.

What Are the Common Repair Issues for Webbing Punch Hole Machines?

Ignoring small issues today means expensive breakdowns tomorrow.

Common repair issues include misaligned dies, worn punching heads, motor failures, electrical faults, and feed system jams.

Preventive Maintenance Checklist

| Task | Frequency | Why It Matters |

|---|---|---|

| Clean work area & remove debris | Daily | Prevents jams and overheating |

| Lubricate bearings & slides | Weekly | Reduces friction and wear |

| Inspect dies and punches | Bi-weekly | Ensures clean cuts and prevents fraying |

| Check motor belts & tension | Monthly | Avoids sudden stoppages |

| Electrical inspection | Every 3 months | Detects loose wiring and potential shorts |

| Full professional service | Every 6–12 months | Extends machine lifespan, ensures compliance |

Common Repair Cases We See

Misaligned Dies

- Symptoms: Crooked holes, incomplete punching

- Fix: Realign punch head, recalibrate sensors

Worn Dies or Blades

- Symptoms: Frayed nylon, uneven edges

- Fix: Replace dies based on cycle count or wear pattern

Motor Overheating

- Cause: Poor airflow or outdated clutch systems

- Solution: Upgrade to servo motors (like in our automatic punching cutting machines)

Electrical Faults

- Risks: Relay failure, ungrounded systems

- Prevention: Use UL/CE certified components

Feed System Jams

- Trigger: Debris buildup or misaligned material

- Solution: Regular cleaning + IR sensor monitoring

Real-World Example

One of our European clients bought a used Bubble Wrap Cutting Machine that suffered constant motor failures. After switching to our Protective Foam Cutting Machine—equipped with error detection and servo control—they reduced downtime by 40%. This proves that modern machines + good maintenance = major savings.

Buyer Tips to Avoid Repair Headaches

- ✅ Always request a spare parts kit when purchasing.

- ✅ Train operators in daily cleaning & safety checks.

- ✅ Keep a maintenance logbook—track usage and failures.

- ✅ Use only OEM-certified parts2 for replacements.

- ✅ Schedule remote or onsite technical support before issues escalate.

At Suzhou Haoxinhe, we offer more than machines—we provide lifecycle support. For OEM clients like Mark, that means live video troubleshooting, express shipping of parts, and upgrade guidance as product lines grow.

Conclusion

With proper maintenance, your webbing punch hole machine1 will run smoothly for years—saving you money, time, and stress.

Insights

In my 20+ years working with punching and cutting systems, here’s what I’ve learned:

Factories that treat maintenance as optional spend 3–5x more on repairs than those with preventive schedules.

The machines don’t fail because they’re weak—they fail because they’re pushed without prep.

Most overlooked tasks?

- ✅ Electrical grounding

- ✅ Die life tracking

- ✅ Motor cooling inspection

My best advice? Treat your maintenance logs like production KPIs. The more you track (dies used, lube cycles, emergency stops), the fewer surprises—and the better your punch precision, uptime, and operator safety.

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we build webbing ribbon cutting machines, automatic punching cutting machines, and rotary bevel cutting machines for long-haul performance. Backed by training, spares, and ongoing support, our machines help clients like Mark avoid the hidden costs of poor maintenance—and build smarter factories for the future.