What Features Should You Look for in a Wire Cutting Stripping Machine?

Choosing the wrong wire cutting stripping machine can lead to production bottlenecks and quality issues.

Featured Paragraph:

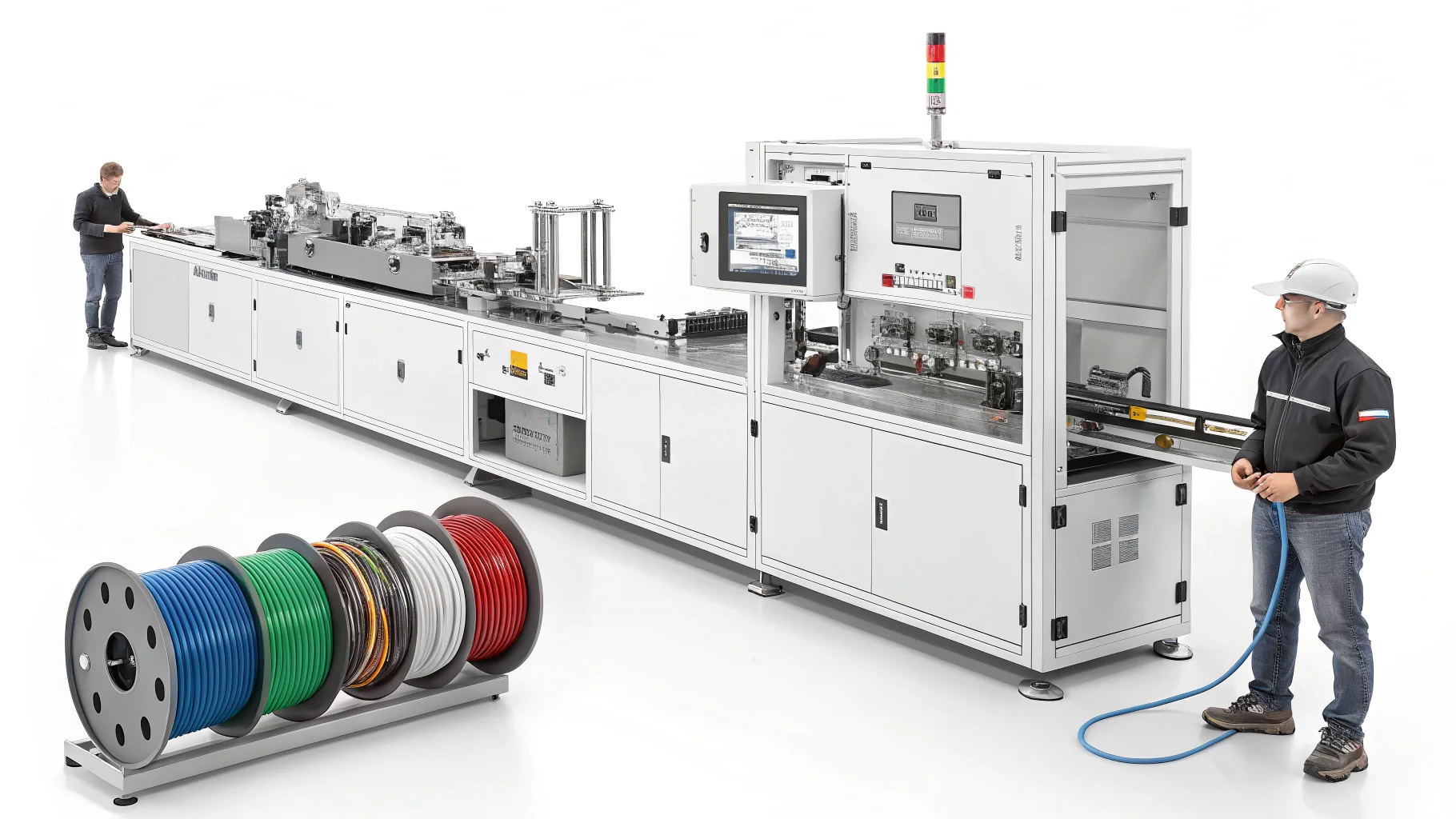

The best wire cutting stripping machines should offer adjustable blade systems for different wire gauges[3], programmable length settings[4], and multi-stage stripping capabilities for complex cables[4]. Look for features like automatic waste collection[1] and self-calibration for consistent performance[2].

How Do Automated Wire Cutting Stripping Machines Improve Cable Harness Production?

Manual wire processing can’t meet the demands of modern cable harness manufacturing.

Featured Paragraph:

Automated wire cutting stripping machines increase production efficiency by 300-500% compared to manual methods[5], while maintaining precision through features like servo-controlled feeders[2] and laser measurement systems[4].

Key Benefits of Automation

| 1. Increased Production Speed | Process | Manual Time | Automated Time | Improvement |

|---|---|---|---|---|

| Cut/strip 10mm² wire | 15-20 sec | 2-3 sec[5] | 500% faster | |

| 50-wire harness | 12-15 min | 2-3 min | 400-500% faster |

2. Advanced Capabilities

- Dual-layer stripping: Simultaneously removes outer jacket and inner insulation[4][6]

- Twisting integration: Some models twist stripped ends for terminal crimping[3]

- Tinning option: Automatic solder coating after stripping[4][6]

3. HAOXINHE’s Production Solutions

Our machines like the EW-8030[2] and HC-515D[5] series feature:

- Touchscreen programming with 200+ wire profiles

- Automatic blade lubrication for continuous operation

- RFID storage for quick recipe changes

Conclusion

For high-volume production, choose machines with modular tool heads and self-diagnostic systems to minimize downtime.

HAOXINHE Insight: Our machines support wire gauges from 0.5mm² to 150mm²[3][4] with customizable stripping configurations. Contact us at cherryhaoxinhesz@gmail.com for a tailored solution.

Keywords Incorporated:

- Fully automatic wire cutting stripping machine[2][4][6]

- Harness wire cutting stripping machine[4]

- Computerized wire cutting stripping machine[3]

- High speed wire cutting stripping machine[2][5]