Using Velcro Dot Cutters in Cable Management and Office Supply Lines?

Tangled cables and messy desktops are common headaches—but many manufacturers are solving this with an unexpected hero: Velcro dot cutters.

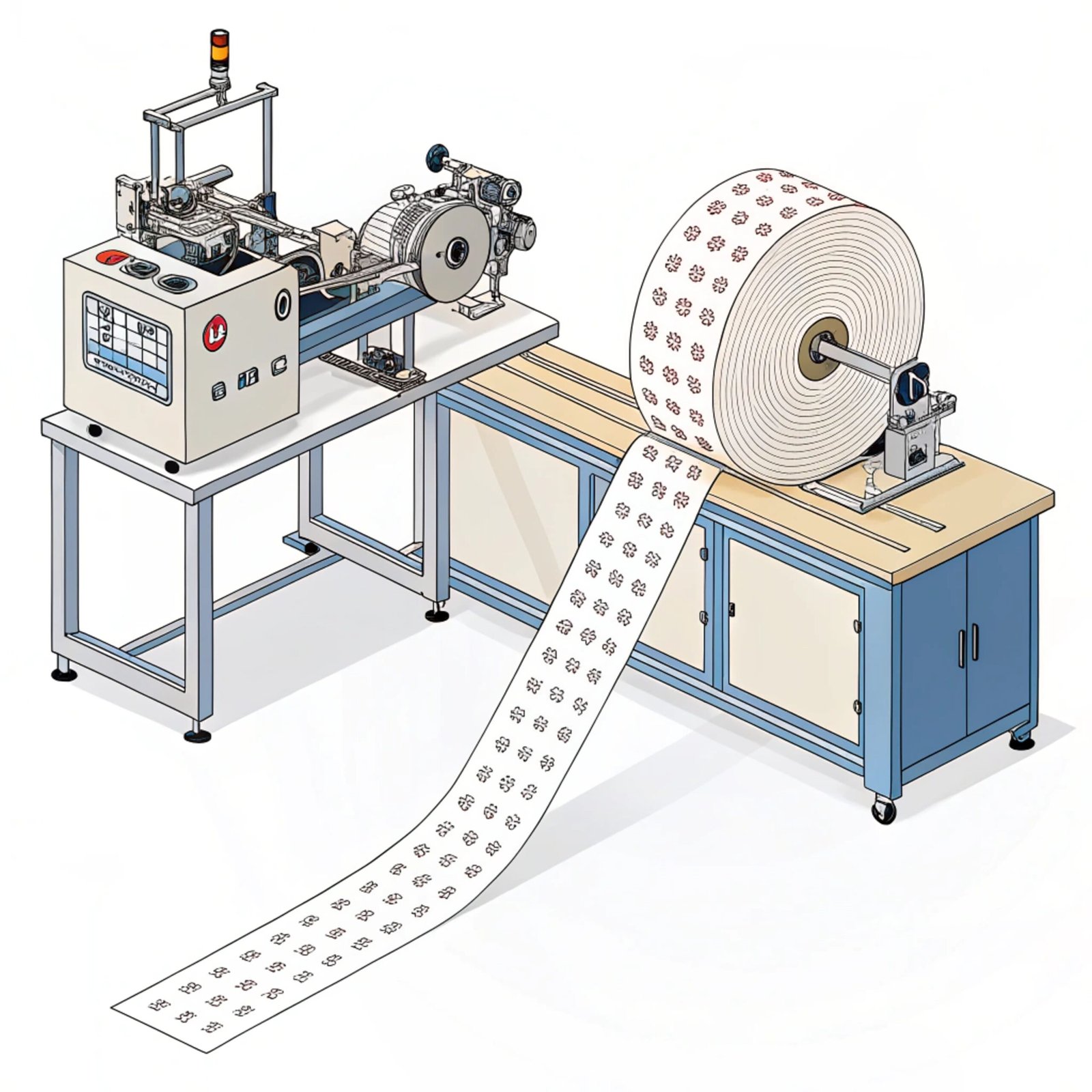

Velcro dot cutters produce consistent fastening solutions used in cable management and office supplies, helping manufacturers scale production with speed and precision.

If you’re in the business of cable ties, reusable wraps, or organizing products, Velcro dot cutters might be your next best investment.

Why is Velcro dot cutting essential in cable management?

Traditional plastic ties are disposable and damage wires. Reusable Velcro dots, on the other hand, offer a gentle and sustainable solution.

Velcro dots are used to fasten cables safely and neatly, especially in IT, home office, and industrial setups.

Velcro dots outperform plastic ties

Reusable Velcro dots are flexible and non-abrasive. They can hold cables without cutting into them. Here’s what they improve:

- Cable longevity: No tight pinching or wire bending

- Organization: Easy to open, adjust, or reposition

- Aesthetics: Available in multiple colors for labeling

With a webbing ribbon cutting machine or round shape cutting machine, factories can mass-produce these dots from rolls of hook-and-loop material. This is especially useful for cable accessory brands that want to add branded or custom-colored options.

How do Velcro dot cutters improve efficiency in office supply manufacturing?

Modern office supplies—from pen holders to binder organizers—are increasingly using Velcro for modularity and reusability.

Automated Velcro dot cutters allow manufacturers to meet high-volume demand with uniformity and speed.

Automation meets growing demand

Office accessory brands are pushing for sustainable and reusable products. Velcro dots are now used to:

- Attach whiteboard tools and markers

- Close binder folders and cases

- Stick items to modular office boards

Our clients use Suzhou Haoxinhe Electrical Equipment Co., Ltd. machines like the automatic punching cutting machine and hot and cold cutting machine to create:

- Circle dots (15mm to 50mm)

- Custom die-cut Velcro pads

- Adhesive-backed fasteners for office tools

Office Supply Use Cases:

| Product | Velcro Application | Machine Type Used |

|---|---|---|

| Marker holder straps | Wall-mounted, reusable | Round shape cutting machine |

| Modular file folders | Adjustable closures | Hot and cold cutting machine |

| Pen case straps | Reusable, color-coded organization | Different shapes cutting machine |

| Modular boards | Sticky Velcro widgets | Rotary bevel cutting machine |

When a U.S. office brand approached us with a unique pen holder idea using magnetic strips and Velcro, we helped them customize production using our protective foam cutting machine to handle both foam and loop backing in one cut cycle.

What customization features do these machines offer for cable and office markets?

Cable ties and office tools often require more than simple black dots—they need logos, colors, adhesives, and specific sizes.

Velcro dot cutters from Suzhou Haoxinhe Electrical Equipment Co., Ltd. support full customization, including size, shape, material, and branding.

Create more than just circles

Whether your customers want:

- Color-coded cable wraps (blue for network, red for power)

- Company logos on Velcro dots

- Fire-retardant adhesive-backed Velcro for office safety

We have a solution. Our different shapes cutting machine and rotary bevel cutting machine can be upgraded with:

- Logo embossing molds

- Roll-to-roll feeding for industrial efficiency

- Adhesive application lines

Customization Chart:

| Feature | Custom Option | Benefit for Manufacturer |

|---|---|---|

| Color | Any Pantone | Color coding for cables or departments |

| Shape | Circle, square, oval, custom dies | Product-matching aesthetics |

| Material Type | Sew-on, adhesive, flame-retardant | Industry compliance (IT, healthcare) |

| Branding | Logo cut or print | Brand visibility and resale value |

Clients sourcing from China or Vietnam often complain about inflexible equipment. But with our modular approach, you can start with basic models like the bubble wrap cutting machine and later scale with full add-ons.

How do these machines support high-volume B2B supply chains?

If you’re supplying Velcro accessories in bulk, you need a cutting process that supports scale—without sacrificing accuracy or increasing defects.

Our machines are designed for high-speed operation and easy integration into B2B production lines, with low downtime and minimal human input.

Engineered for enterprise production

Suzhou Haoxinhe Electrical Equipment Co., Ltd. is a factory with 5 full production lines. We built our machines for the kind of manufacturers that serve:

- Office supply distributors

- IT and electronics wholesalers

- Cable accessory brands

That’s why our machines like the computer tube cutting machine or metal pipe cutting and beveling machine are made to run:

- 24/7 shifts

- With remote diagnostics

- Using universal parts for fast maintenance

Supply Chain Advantages:

| Feature | Benefit |

|---|---|

| Roll-to-dot automation | Bulk processing of Velcro rolls |

| Custom dies and feeding | Zero changeover downtime |

| CE/ISO-certified equipment | Export-ready for EU/North America |

| Local training and support | Remote video + manual guides |

We’ve supported companies in Germany, Singapore, and North America who needed scalable machines that comply with local safety standards while keeping unit costs low.

Conclusion

Velcro dot cutters help streamline production for cable management and office supply products—delivering quality, speed, and customizability.

Insights

Automatic Velcro dot cutters simplify the mass production of reusable cable ties and modular office tools. With customizable options and fast output, they help factories meet modern demand while reducing labor and improving consistency.