The Best Circle Velcro Punching Machine for Sofa and Carpet Products?

Sofa and carpet factories often need high-volume, perfectly round Velcro pieces. But using scissors or manual punches just doesn’t cut it anymore.

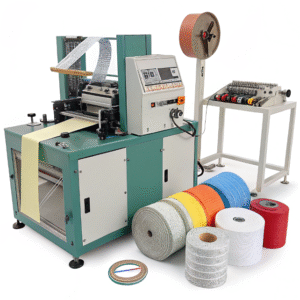

A circle Velcro punching machine is the most efficient and precise tool for producing round Velcro components used in upholstery and flooring applications.

If you’re struggling with inconsistent sizes or labor-intensive cutting, this post will walk you through why these machines are game-changers for soft furniture and carpet manufacturers.

Why do sofa and carpet products need circle Velcro?

From removable couch cushions to carpet tiles that stick to floors without glue—Velcro offers clean, adjustable, and damage-free attachment solutions.

Circle Velcro pieces make furniture components more modular, easier to clean, and visually seamless—especially compared to rectangular strips.

Functional and aesthetic value

In the furniture and flooring world, small design choices make a big difference. Round Velcro dots:

- Create a cleaner, less intrusive look

- Provide strong hold without sharp edges

- Enable easy removal and repositioning of fabric panels or floor sections

I once worked with an Italian sofa factory that used hot glue for years. But they switched to our round shape cutting machine to cut custom Velcro dots. Their fabric maintenance team could now remove covers in seconds—leading to fewer warranty claims and higher customer satisfaction.

What makes a circle Velcro punching machine better than manual methods?

Manually cutting circles is slow, inconsistent, and causes waste—especially when using industrial-grade Velcro.

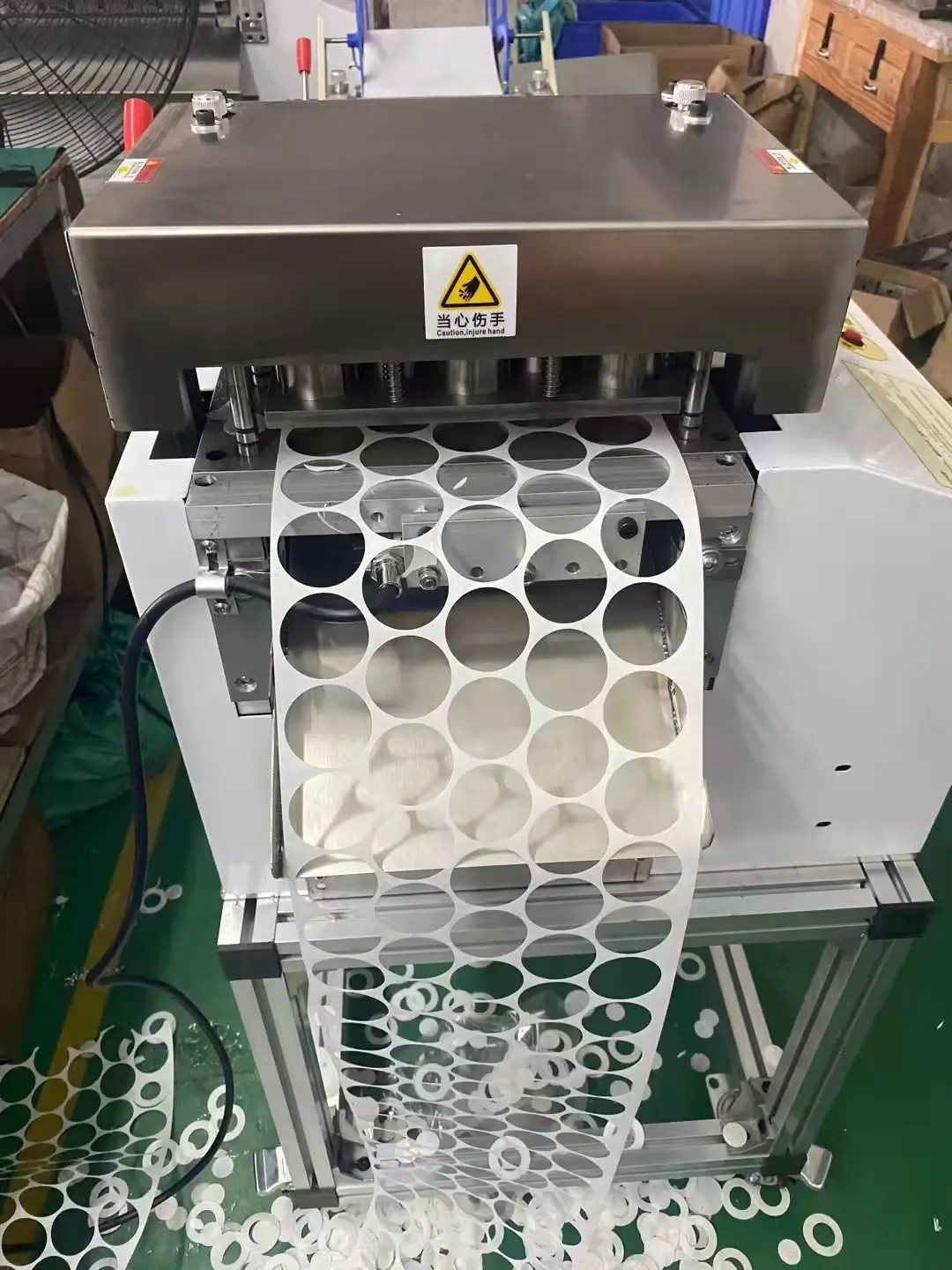

A circle Velcro punching machine automates the cutting process with precision, saving time, reducing labor, and increasing product consistency.

Precision at scale

Manual punching with hand tools results in:

- Irregular edges

- Uneven sizes

- Worker fatigue

By contrast, our rotary bevel cutting machine and automatic punching cutting machine offer:

- Precise, clean-edge cuts every time

- Adjustable die sizes (commonly 20mm–50mm circles)

- Continuous operation for mass production

Comparison Table:

| Feature | Manual Cutting | Circle Punching Machine |

|---|---|---|

| Output per Hour | ~300 dots | 3,000–8,000 dots |

| Edge Quality | Rough | Smooth and sealed |

| Material Waste | High | Minimal |

| Labor Required | Multiple workers | One operator |

| Custom Die Integration | Not possible | Fully supported |

Many of our customers use Suzhou Haoxinhe Electrical Equipment Co., Ltd. punching machines to cut industrial-strength Velcro rolls with ease. They report 70% faster throughput after upgrading from manual setups.

How does the machine adapt to different Velcro materials?

Not all Velcro is the same. Upholstery often uses thicker, industrial-grade types. Carpets need adhesive-backed versions that resist movement and wear.

Circle Velcro punching machines can be customized for various materials, thicknesses, and adhesives—ensuring clean cuts across all use cases.

Versatility is built in

Whether you’re working with:

- Sew-on loop Velcro for sofa panels

- Adhesive hook dots for carpet tiles

- Fire-retardant Velcro for hotel furniture

Our machines like the webbing ribbon cutting machine or hot and cold cutting machine can be tailored to the task. Features include:

- Temperature adjustment for adhesive materials

- High-pressure dies for thick industrial Velcro

- Die change system for fast shape switching

Supported Velcro Specifications:

| Type | Application | Compatible Machine Models |

|---|---|---|

| Adhesive-backed Hook Tape | Carpet tile placement | Hot and cold cutting machine |

| Loop Sew-on Tape | Sofa cushion attachment | Round shape cutting machine |

| Fire-retardant Velcro | Commercial seating | Protective foam cutting machine |

| Colored Decorative Velcro | Designer furniture panels | Different shapes cutting machine + rotary bevel |

One of our Canadian clients uses our metal pipe cutting and beveling machine alongside the punching system to mount Velcro to carpet stands. This integration shows how machines from Suzhou Haoxinhe Electrical Equipment Co., Ltd. work together in real production lines.

What are the ROI and long-term benefits for furniture factories?

A specialized machine sounds expensive at first—but compared to high labor costs and waste from manual cutting, it quickly pays for itself.

Circle Velcro punching machines reduce labor, lower defect rates, and support scalability—making them an essential long-term investment for furniture and carpet factories.

Numbers speak louder than promises

Let’s break down how a small factory benefits:

- Labor costs drop: One machine replaces 3–5 manual workers.

- Defect rate drops: No more irregular circles that get rejected during QC.

- Production time shrinks: Faster Velcro prep means quicker final assembly.

ROI Estimation Table (12-month period):

| Cost Category | Manual Method | Circle Punching Machine |

|---|---|---|

| Initial Setup | Low (~$500 tools) | Medium (~$3,000–$6,000) |

| Monthly Labor (2 workers) | $2,400 | $400 (1 machine operator) |

| Material Waste (%) | 20% | 5% |

| Annual Output | 240,000 dots | 1,000,000+ dots |

| Break-even Period | — | ~4 months |

The real benefit comes from consistency. Customers remember when furniture parts fit seamlessly or carpet tiles stay in place—and they come back for more.

Conclusion

A circle Velcro punching machine is a must-have for any furniture or carpet manufacturer serious about quality, speed, and cost-efficiency.

Insights

Circle Velcro punching machines offer fast, precise, and customizable cutting solutions for sofa and carpet products. They improve production speed, reduce labor costs, and deliver a professional finish—making them essential for scalable, high-quality manufacturing.