Bubble Wrap Cutting Machine Maintenance Tips to Lower Long-Term Costs?

Even the best machine needs care — and small issues can lead to big downtime if ignored.

Regular maintenance on your bubble wrap cutting machine1 reduces breakdowns, extends its life, and keeps your packaging line running smoothly — saving money over time.

Here’s how to keep your equipment in top shape and avoid costly interruptions.

Why is maintenance critical for bubble wrap cutters?

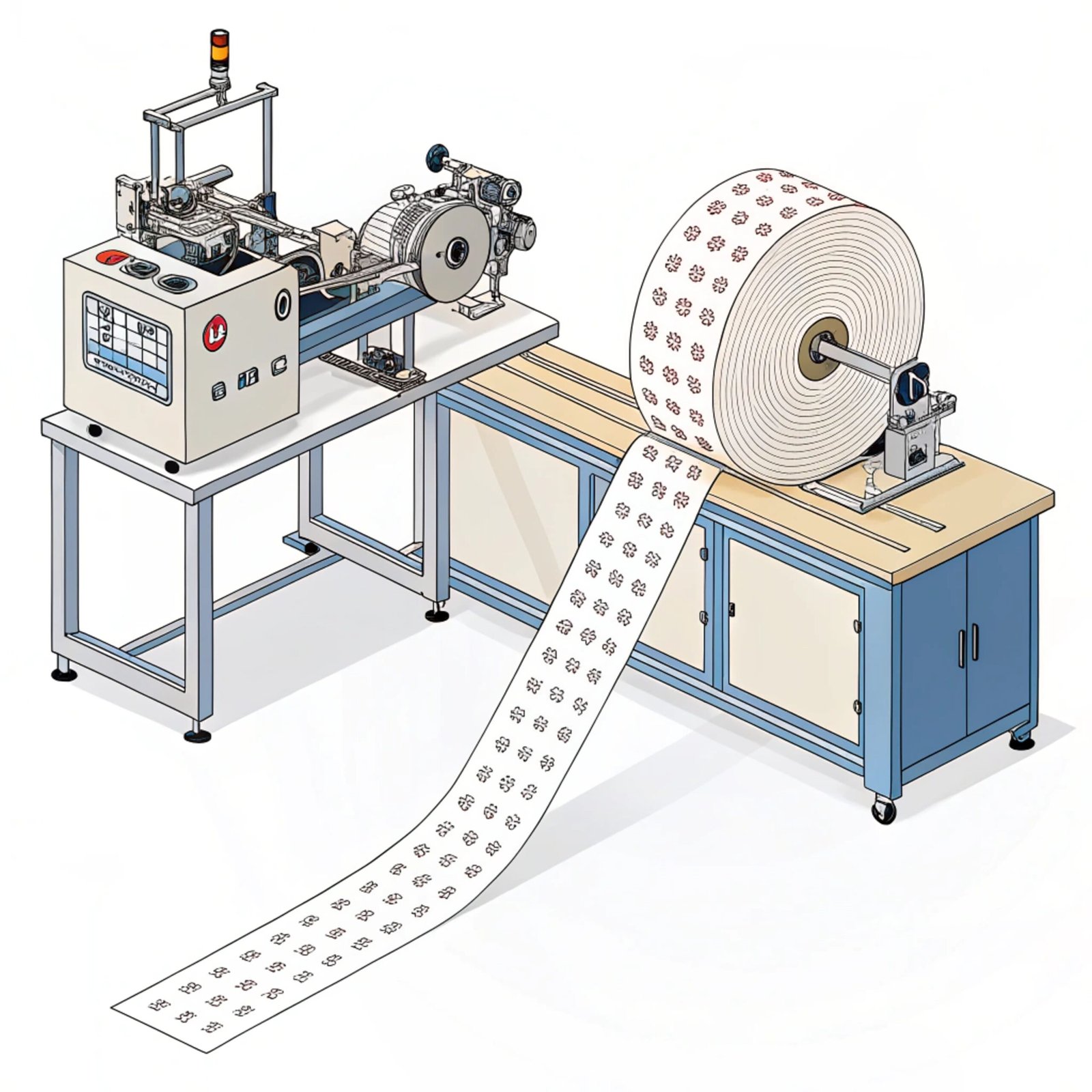

[^2] checklist, Ensuring smooth operation with regular checks](https://hxcuttingmachine.com/wp-content/uploads/2025/03/23-md-image-generation-for-industrial-aluminum-f.jpg)

Packaging departments often run non-stop — and even minor blade misalignments or dust buildup can derail productivity.

Preventive maintenance ensures your machine stays accurate, safe, and efficient — avoiding unexpected repair costs and delays.

Benefits of Routine Maintenance

- ✅ Fewer unplanned stoppages

- ✅ Longer machine lifespan

- ✅ Lower replacement part costs

- ✅ Improved cutting accuracy

- ✅ Safer operation for your team

Over time, consistent care can cut your total cost of ownership by 20–30%.

Daily Maintenance: Quick Checks for Operators

Most problems start small — daily checks keep them from growing.

Train your operators to run simple inspections at the start and end of each shift.

Daily Checklist

- ✅ Wipe dust from rollers and frame

- ✅ Inspect feed belt for wear or slack

- ✅ Check blade area for debris buildup

- ✅ Confirm cutting length matches setting

- ✅ Ensure emergency stop is working

- ✅ Power off properly after use

These take less than 5 minutes and prevent 80% of common issues.

Weekly Maintenance: Keep It Cutting Clean

Debris from wrap or static buildup can affect roller grip and blade sharpness.

Weekly tasks involve cleaning, minor adjustments, and visual checks of moving parts.

Weekly Tasks

| Task | Why It’s Important |

|---|---|

| Clean blade and cutter housing | Prevent sticky buildup or drag |

| Lubricate moving guides | Reduce friction and motor load |

| Check rollers for nicks or warping | Ensure smooth material feed |

| Inspect tension controls | Maintain wrap alignment and accuracy |

| Recalibrate if cuts drift | Keep ±1mm cutting precision |

Use non-abrasive cleaners and anti-static wipes to avoid damage.

Monthly Maintenance: Inspect and Tighten

Every 30 days, schedule deeper maintenance to check core systems and bolts.

This prevents vibrations, alignment drift, and early motor wear.

Monthly Tune-Up Tasks

- ✅ Tighten frame bolts and supports

- ✅ Check power cables for wear

- ✅ Clean intake vents or cooling fans

- ✅ Run a test batch at multiple speeds

- ✅ Review error logs or alerts on interface

- ✅ Replace blade if cuts are no longer clean

If your facility runs 24/7, consider doing this twice per month.

Blade Maintenance: When and How to Replace

The blade is the most used component — and a dull blade causes poor cuts and damaged bubble cells.

Most blades last 1–3 months, depending on usage. Replace when cuts become jagged or take longer to complete.

Signs You Need a New Blade

- Irregular edge finish

- Bubble crushing at the cut site

- Wrap sticks to the blade

- Motor sounds strained during cut

- Length output becomes inconsistent

Replacement Tips

- Always use manufacturer-approved blades

- Wear gloves and power off the machine

- Align new blade exactly with calibration marks

- Reset cut settings after installation

Haoxinhe machines come with a spare blade kit and full video instructions for easy replacement.

Troubleshooting Tips to Avoid Downtime

Most breakdowns are avoidable with early detection.

Train staff to recognize warning signs and take quick action.

Common Issues & Fixes

| Symptom | Likely Cause | Fix |

|---|---|---|

| Feed stops mid-cycle | Dirty rollers | Clean + check tension |

| Wrap skews during feed | Misaligned roll | Re-center and adjust tension |

| Cutter won’t start | Safety lockout engaged | Check guard and emergency stop |

| Length off by 10mm+ | Sensor misread or stretch | Recalibrate + inspect sensor |

| Unclean cuts | Dull blade | Replace with new blade |

Keeping a simple troubleshooting chart at the station can prevent panic and speed up recovery.

Long-Term Maintenance Planning

Plan ahead to minimize downtime and reduce emergency costs.

Create a maintenance schedule and track it using a log or calendar.

Suggested Schedule

| Frequency | Task |

|---|---|

| Daily | Operator cleaning and check |

| Weekly | Blade area, rollers, belt |

| Monthly | Frame, sensors, speed test |

| Quarterly | Full recalibration + optional factory support |

Include inspection checklists, blade replacement logs, and issue tracking for every machine.

Why Haoxinhe Machines Are Maintenance-Friendly

We design our machines to work hard — and maintain easily.

Suzhou Haoxinhe Electrical Equipment Co., Ltd. includes low-maintenance features, spare parts, and global support with every bubble wrap cutter.

Our Maintenance Advantages

- ⚙️ Tool-free access panels

- 🛠️ Long-life blades with quick-swap mounts

- 🔧 Clear calibration guides built into the UI

- 🎥 Video tutorials + remote support

- 📦 Extra blades and parts with every shipment

- 🌐 Support in English, French, and Chinese

We also manufacture:

- Velcro dot cutters

- Label and foam sheet cutters

- PVC edge banding machines

- Webbing ribbon cutting systems

Trusted by packaging teams in Europe, North America, Southeast Asia, and beyond.

Conclusion

With basic care, your bubble wrap cutting machine will deliver consistent performance for years. Stay on top of cleaning, calibration, and blade changes — and your ROI will keep growing.

Insights

Regular maintenance is key to lowering long-term costs in packaging automation. Suzhou Haoxinhe’s bubble wrap cutters are designed for easy upkeep — with tool-free access, durable parts, and global support to help your team prevent downtime and maximize efficiency.

Explore this resource to learn essential maintenance tips that can extend the life of your bubble wrap cutting machine and reduce costs. ↩