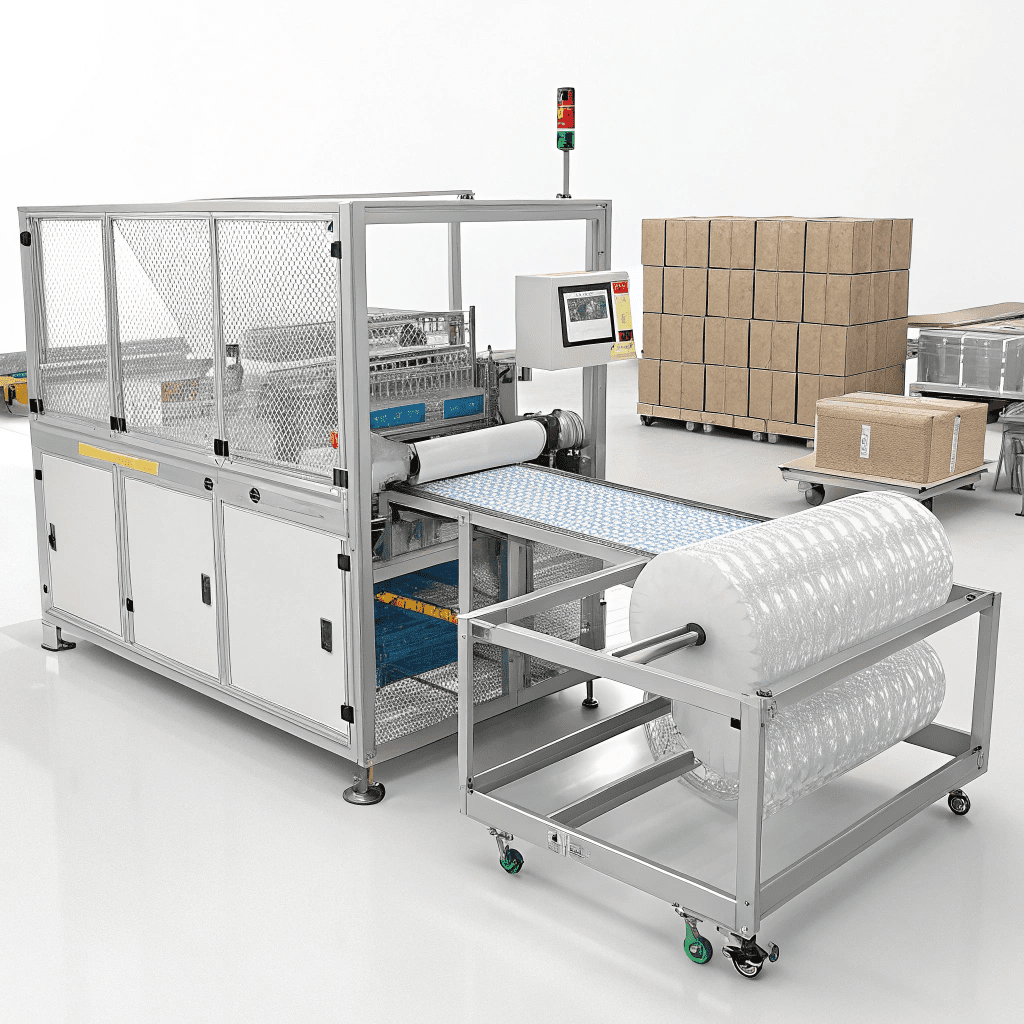

Integrating a Bubble Wrap Cutting Machine into Your Production Line?

Your packaging team is fast — but cutting wrap manually still slows everything down.

Integrating a bubble wrap cutting machine1 into your production line streamlines protective packaging, reduces labor, and keeps your operation moving at full speed.

Here’s how to successfully add this machine into your workflow — and what to consider before installation.

Why integrate, instead of operating separately?

Manual cutting might seem manageable — until your volume grows, and packaging becomes a bottleneck.

Integrating a cutting machine directly into the line turns bubble wrap prep into a seamless, automatic step — eliminating downtime and cutting waste.

Key Benefits

- Inline automation: Sheets ready exactly when needed

- Reduced handling: No pre-cutting, storing, or trimming

- Faster wrapping: Operators wrap, not measure and cut

- Consistent output: Every sheet is the same size

- Cleaner floors: No wrap piles or scrap offcuts

This is ideal for factories packaging electronics, furniture, appliances, or fragile consumer goods.

Step 1: Choose the Right Machine for Integration

Not every cutter is made to be inline — integration-ready models offer syncing, auto-feed, and conveyor compatibility.

Look for a machine that supports programmable length, multiple speeds, and front-end access for line placement.

Features You’ll Need

| Function | Why It Matters |

|---|---|

| Programmable Cut Length | Match different product sizes |

| Servo Motor Feed System | Syncs with other line equipment |

| Conveyor-Compatible Output | Feeds wrap directly into next stage |

| Emergency Stop & Safety Sensors | Protect workers on shared lines |

| Variable Speed Control | Adjust to match packaging pace |

At Suzhou Haoxinhe, our HXN-BWC series supports all of the above — built for factory-floor performance.

Step 2: Decide on Integration Point

Your machine should be installed where it adds speed, not clutter.

Ideal integration points are near the final assembly or packing area — where the product gets bubble-wrapped before boxing.

Common Integration Points

| Line Stage | Use Case |

|---|---|

| End of Assembly | Wrap exposed surfaces before boxing |

| Start of Packing Table | Operator grabs wrap as needed |

| Inline with Conveyor | Machine cuts + drops onto moving belt |

| Central Bubble Wrap Station | Feeds 2–3 lines from one machine |

You’ll want to keep cut wrap accessible, but out of the way — some teams add a drop bin or tray for clean collection.

Step 3: Configure Sheet Sizes for SKUs

Different products need different protection — chairs and circuit boards won’t share the same wrap.

Use the cutter’s touchscreen or interface to set common sheet sizes, then assign each one to a preset program.

Example Presets

| Product | Cut Length |

|---|---|

| Tablet PC | 300mm |

| Monitor | 600mm |

| Cabinet Door | 1000mm |

| Appliance Panel | 1200mm |

| Full TV Wrap | 1500mm |

You can switch sizes in seconds between runs — no recalibration needed.

Step 4: Train Your Team

A good machine is only effective if operators know how to use it.

Train your team to load rolls, select cut programs, and monitor performance — and you’ll see results immediately.

Training Topics

- Loading and aligning rolls

- Using the touchscreen interface

- Adjusting length and speed settings

- Performing test cuts

- Clearing jams or feeding issues

- Safety procedures and shutdown

Suzhou Haoxinhe provides video tutorials, live setup support, and manuals in English, French, and Chinese.

Step 5: Monitor Results and Optimize

Once installed, track how much time and material you save — and adjust for even greater output.

Use internal tracking or optional machine counters to measure performance across shifts.

Key Metrics

| Metric | Why It Matters |

|---|---|

| Sheets/hour | Shows real output rate |

| Wrap usage | Confirms waste reduction |

| Downtime logs | Identifies bottlenecks |

| Changeover speed | Measures shift between SKUs |

Some factories report 30–50% packaging time savings after full integration — and even more when combined with other automation.

Why integrate with Suzhou Haoxinhe?

You don’t just need a machine — you need a system that fits your line.

Suzhou Haoxinhe Electrical Equipment Co., Ltd. specializes in cutting automation for packaging, offering tailored solutions for electronics, furniture, appliances, and more.

What We Offer

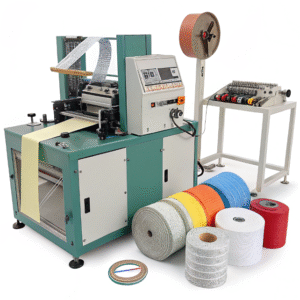

- Cut lengths: 200mm–3000mm+

- Roll widths: up to 1500mm

- Cold, hot, and perforated cutting options

- Touchscreen interfaces with memory presets

- Compact, conveyor-ready designs

- Global delivery in 7–15 days

- Remote setup + multilingual support

We also build:

- Velcro dot and foam cutters

- Webbing and PVC edge cutters

- Roll-to-roll and label cutting systems

Already trusted by clients in Germany, Canada, Singapore, and Italy, our machines are built for real production environments.

Conclusion

Integrating a bubble wrap cutter into your production line eliminates wasteful manual steps and keeps your packaging operation moving fast, clean, and efficiently.

Insights

To scale protective packaging, integrating a bubble wrap cutting machine into your production line is essential. Suzhou Haoxinhe offers programmable, high-speed cutters that fit seamlessly into factory workflows — boosting speed, consistency, and cost-efficiency across industries.

Explore the advantages of integrating a bubble wrap cutting machine to enhance efficiency and reduce waste in your production line. ↩