Exhibitions Made Easy: Velcro Dot Mounting Solutions?

Trade shows are fast – paced and demanding — you need displays that set up quickly and stick without damage.

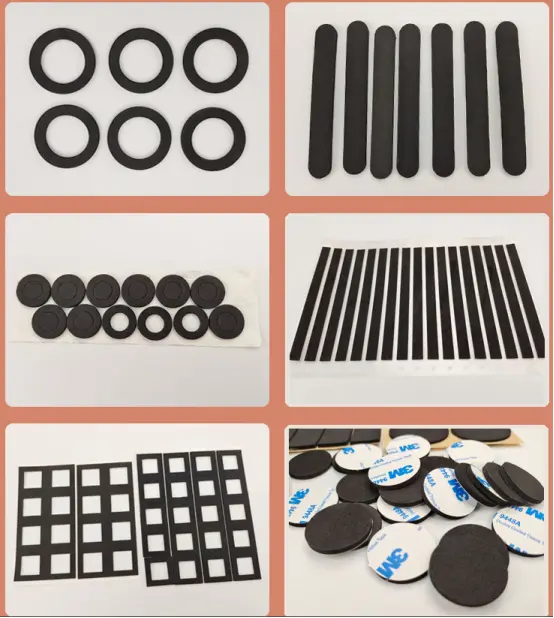

Velcro dot mounting solutions offer a clean, reusable, and efficient way to assemble exhibition displays — and our cutting machines help you produce them at scale.

Let’s explore how these solutions transform booth setup, while saving time and improving presentation.

Why are Velcro dots ideal for exhibition displays?

Screws and adhesives are permanent and messy — but exhibitions need flexibility and speed.

Velcro dots allow for tool – free, adjustable mounting of banners, signs, and modular panels, making setup and teardown fast and stress – free.

Key Benefits in Exhibitions

- Quick Installation: Just peel and press

- No Surface Damage: Safe for walls, frames, and banners

- Modular Use: Rearrange displays without tools

- Reusable: Dots last through multiple events

- Compact Transport: Easy to pack, light to carry

Common Trade Show Applications

| Display Element | Velcro Dot Function |

|---|---|

| PVC or Foam Boards | Easy attachment to frames or truss |

| Brochure Holders | Temporary mounting on walls |

| Light Signage | Stick to fabric or partition panels |

| Backdrops | Reconfigurable layout using Velcro |

| Sample Displays | Secure lightweight items to boards |

With thousands of booths at every event, your brand has seconds to make an impression — clean displays help you stand out.

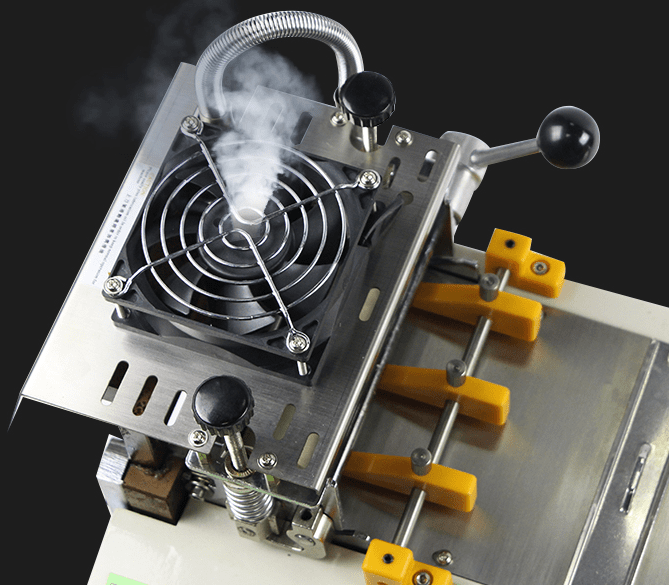

How do we produce Velcro dots for exhibitions?

Cutting Velcro by hand is slow, inconsistent, and not scalable.

Our Velcro dot cutting machines automate the production of adhesive – backed Velcro dots, offering ±0.2mm precision and 10,000+ pcs/hour output.

How It Works

- Load adhesive – backed hook or loop tape

- Choose dot size (10mm–30mm+)

- Rotary die cutter slices consistent dots

- Waste is separated automatically

- Finished dots roll or drop into collection bin

These dots can be packed onto liner rolls or bagged — perfect for exhibition kit assembly and logistics.

Machine Features

- Cold – cut mode for adhesive – backed Velcro

- Multiple die sizes available

- Compact models for workshops or factories

- Quick die change system

- Supports eco/recycled Velcro

You can produce branded or blank dots in any volume needed for your events or customers.

What makes Velcro dot mounting better than alternatives?

Exhibitors need fast, clean setups — not tools or waiting for glue to dry.

Velcro dots outperform traditional mounting methods by offering instant setup with zero cleanup or damage.

| Mounting Method | Tools Needed | Reusable | Surface Safe | Time to Apply |

|---|---|---|---|---|

| Screws/Bolts | Drill, screwdriver | ❌ | ❌ | 10–20 mins |

| Adhesive Glue | None | ❌ | ❌ (leaves marks) | 15–30 mins |

| Velcro Dots | None | ✅ | ✅ | <1 min |

This makes them ideal for fast – paced show schedules, rotating displays, or traveling demo kits — no damage, no delay.

Use Case: Event Marketing Firm (Canada)

- Manages booth builds for 30+ clients per season

- Used to rely on 3M tape or hardware

- Switched to Velcro dots:

- Setup time reduced by 60%

- Reuse rate improved

- No post – event wall repair needed

They now source custom – cut Velcro dots in their own brand color — with our Haoxinhe rotary dot cutter.

What Velcro materials and sizes work best?

Different booth setups require different dot strengths, sizes, and backing types.

Our machines support adhesive – backed hook and loop materials in a wide range of sizes and types — all tailored for clean exhibition installs.

Dot Sizes for Exhibits

| Size | Ideal Use |

|---|---|

| 10mm | Small signs or cards |

| 15mm | Lightweight holders |

| 20mm | Foamboard signs, A4 panels |

| 25mm | Modular banners |

| 30mm+ | Sample kits, backdrops |

Supported Materials

| Material Type | Compatible | Notes |

|---|---|---|

| Adhesive – Backed Hook | ✅ | Strong mounting base |

| Adhesive – Backed Loop | ✅ | Soft side for removable pieces |

| Colored Velcro | ✅ | Brand – matching options |

| Eco – Friendly Velcro | ✅ | For sustainable exhibits |

Whether you supply dot rolls, pre – cut packs, or exhibition toolkits — our machine supports your format.

Why choose Suzhou Haoxinhe for Velcro dot production?

You need fast, accurate, and reliable machines — backed by a team that understands your use case.

Suzhou Haoxinhe Electrical Equipment Co., Ltd. is a certified manufacturer of Velcro cutting machines, with 5 production lines and customers worldwide.

Why Clients Choose Us

- Factory – direct machines — no resellers

- Fast delivery (7–15 days globally)

- Custom die support for dot, square, or branded shapes

- Cold – cut and hot – cut modes

- Multilingual support (EN, FR, CN)

- Remote training and spare parts packages

We also offer:

- Webbing ribbon cutting machines

- Protective foam cutters

- Punching and rewinding systems

- Velcro dot and label cutters for other industries

Whether you’re a printer, booth supplier, or marketing firm — we’ll help you cut faster and exhibit better.

Conclusion

Velcro dot mounting makes exhibition setups clean, fast, and reusable. With our cutting machines, you can produce thousands of dots with ease — ready for your next event.

Insights

Exhibitions require flexible, reusable, and damage – free mounting. Suzhou Haoxinhe’s Velcro dot cutting machines help suppliers produce high volumes of adhesive – backed hook & loop dots quickly and precisely. Ideal for banners, modular displays, and trade show booths — these machines power modern event logistics.