Eco – Friendly Packaging with Velcro Dot Cutting Machines?

Sustainable packaging is trending — but glue and tape don’t always fit the green bill.

Velcro dot cutting machines help brands create reusable, recyclable, and clean packaging closures — with precision and speed, minus the waste.

This article explores how you can cut Velcro dots more efficiently for eco – friendly packaging without sacrificing function or aesthetics.

Why use Velcro dots in sustainable packaging?

Sustainable packaging needs to be reusable, non – toxic, and easy to recycle — yet still strong and secure.

Velcro dots offer a non – permanent, reusable alternative to glue, plastic clips, or single – use seals — perfect for eco – conscious product lines.

Why It Works

- Reusability: Open and close the package again and again

- No Residue: Doesn’t damage recycled materials

- Recyclable: Works with biodegradable or FSC – certified boards

- Consumer – Friendly: Adds perceived value and usability

- Safe for Kids & Food: No sharp parts, adhesives, or heat sealing

Common Sustainable Packaging Uses

| Product Type | Velcro Dot Function |

|---|---|

| Recyclable Gift Boxes | Reusable closures |

| Craft Kits | Resealable compartments |

| Subscription Boxes | Eco – friendly seals |

| Cosmetic Packaging | Reusable pouch or insert fasteners |

| Children’s Toys | Tamper – free, resealable safety enclosures |

The challenge? Cutting Velcro cleanly, especially in round shapes, without creating waste or damaging sensitive materials.

How does a Velcro dot cutting machine help?

Manual cutting = uneven shapes, wasted material, and low production speed.

A Velcro dot cutting machine automates the process, giving you clean, repeatable cuts with low material waste — critical for sustainable manufacturing.

Machine Features

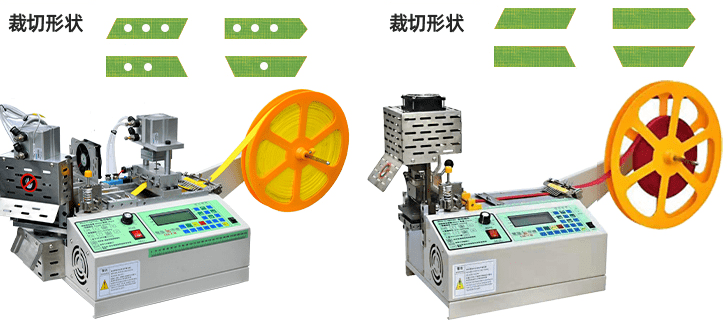

- Rotary Die Cutting System

Cuts circular or custom Velcro shapes continuously - Cold Cutting Option

Ideal for adhesive – backed eco Velcro (no glue melting) - Minimal Waste

Precision edge cutting reduces offcuts - High Output

Up to 10,000+ dots/hour - Reusable Die System

Long life tooling minimizes replacement parts

| Manual Cutting | Haoxinhe Dot Cutter | |

|---|---|---|

| Output/hr | 300–800 pcs | 10,000+ pcs |

| Edge Quality | Irregular | ±0.2mm accuracy |

| Material Waste | High | <3% |

| Worker Fatigue | High | Low (1 operator) |

With these features, even small eco brands can deliver big – brand packaging quality — without the labor or waste.

What sustainable Velcro materials does it support?

Not all hook and loop is the same. Some are now made with recycled yarns or biodegradable binders.

Our cutting machines are compatible with eco – friendly Velcro types, including low – profile loop, recycled materials, and non – toxic adhesive backing.

Supported Materials

| Velcro Type | Eco Status | Machine Compatible? |

|---|---|---|

| Nylon (Recycled) | ♻️ | ✅ |

| Polyester Soft Loop | ♻️ | ✅ |

| Adhesive – Backed (Non – toxic) | ♻️ | ✅ |

| Biodegradable Hook | ♻️ | ✅ (Cold mode recommended) |

| Recycled PET Velcro | ♻️ | ✅ |

If you’re working with FSC – certified boxes, soy – based inks, or paper pulp inserts — Velcro dots are a clean, effective way to fasten without glue, staples, or magnets.

How does it support green production goals?

Being green isn’t just about materials — it’s about how you produce them.

Our machines are designed for energy efficiency, low maintenance, and high material yield — supporting your sustainability efforts across the board.

Sustainable Production Benefits

Energy – Efficient Motor Design

Lower power consumption compared to thermal cutting machinesReusable Dies

Die heads last for years with simple maintenanceMinimal Operator Training

Reduces human error and material wasteSmart Batch Controls

Programmable interface to cut only what you need, when you need itCompact Footprint

Suitable for small workshops, low impact on factory layout

Example: Eco Packaging Brand (Netherlands)

- Packaging handmade cosmetics in kraft boxes

- Previously used single – use stickers (not recyclable)

- Switched to biodegradable Velcro dots + Haoxinhe cutter

- Output doubled

- Dot waste reduced by 75%

- Customer feedback improved due to resealability and aesthetics

Why choose Suzhou Haoxinhe for sustainable packaging automation?

You need a partner that understands industrial efficiency and eco – conscious production.

Suzhou Haoxinhe Electrical Equipment Co., Ltd. is a trusted Chinese manufacturer offering cutting machines with sustainability and scale in mind.

What We Offer

CE / ISO Certified Machines

For global export complianceCustom Die Services

Star, circle, tab — any shape for branded sustainable packagingLow – Energy Models

Designed for low emissions and minimal power drawMultilingual Sales & Support

English, French, and Chinese teams7–15 Day Global Shipping

To Europe, North America, Asia, and beyond

We also offer:

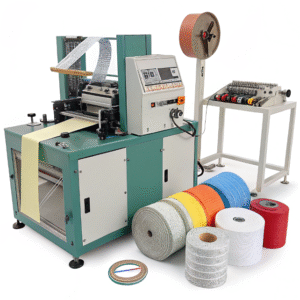

- Webbing ribbon cutters

- Hot and cold Velcro cutters

- Rotary die systems

- Protective foam and edge banding cutters

Conclusion

If your business values sustainability and speed, our Velcro dot cutting machines help you deliver reusable, eco – friendly packaging — with no mess, no glue, and no compromise.

Insights

Eco – conscious brands can streamline packaging production with Velcro dot cutting machines from Suzhou Haoxinhe. These machines cut recycled or biodegradable Velcro materials into precise shapes, support adhesive – backed options, and reduce labor and waste — ideal for reusable, sustainable packaging in cosmetics, toys, and gifts.