Choosing the Right Velcro Cutter for Multi – Sector Manufacturing?

Not all Velcro cutting needs are the same — and using the wrong machine can waste time, material, and money.

At Suzhou Haoxinhe, we help multi – sector manufacturers choose the right Velcro cutting machine for their products, industries, and production goals.

Let’s explore how to match the right cutter to your sector, whether you’re producing for medical, apparel, electronics, packaging, or industrial applications.

Why is choosing the right Velcro cutter critical?

Different industries use Velcro in different ways — and what works for packaging may fail in electronics or medical.

Choosing the right Velcro cutting machine ensures material compatibility, edge quality, adhesive integrity, and production efficiency across diverse sectors.

Common Use Case Challenges

| Sector | Velcro Use | Challenge |

|---|---|---|

| Medical | Braces, wraps | Requires fray – free precision |

| Apparel | Patches, closures | Needs custom shapes and clean edges |

| Electronics | Cable ties, device mounting | Demands size accuracy and adhesive protection |

| Packaging | Resealable flaps | Requires high volume and adhesive compatibility |

| Industrial | Straps, harnesses | Needs durability and width flexibility |

That’s why Suzhou Haoxinhe offers multiple models of Velcro cutting equipment — so you get what your workflow truly needs.

What types of Velcro cutters are available?

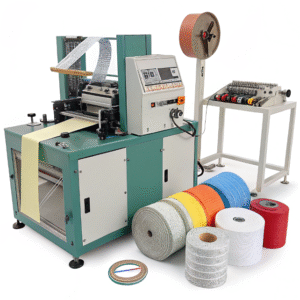

One machine doesn’t fit all. We’ve engineered several specialized machines — each designed to support different Velcro formats, shapes, and material grades.

From flat webbing to adhesive – backed dots and rotary dies, there’s a cutter matched to your operation.

Our Top Velcro Cutting Machines

| Machine | Description | Best For |

|---|---|---|

| Hot & Cold Cutting Machine | Linear cutting with heat/fray control | Straps, belts, industrial webbing |

| Rotary Die Cutter | Continuous dot/shape cutting | Promotional kits, packaging, patches |

| Adhesive Velcro Punching Machine | Punches shapes from sticky – backed Velcro | Labeling, badges, electronics |

| Webbing Ribbon Cutter | Cuts wide or narrow Velcro ribbons | Textiles, cable wraps, PPE straps |

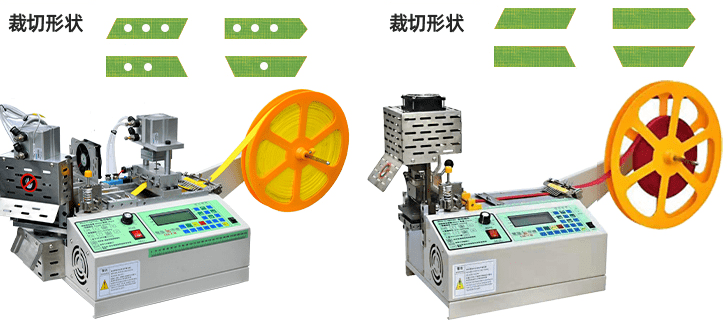

| Dot Cutting Machine (HXN – RDC) | Compact, high – speed dot producer | Medical kits, toys, modular gear |

Each machine supports different widths, speeds, and customization levels, allowing multi – sector clients to scale efficiently without compromise.

How do I match the machine to my materials and sector?

Material type, coating, and format all affect which cutter you need.

We help you choose based on your material (nylon, polyester, foam), coating (adhesive – backed, flame – retardant), and use case (fray – free, custom shape, bulk runs).

Material Compatibility Matrix

| Material Type | Hot & Cold Cutter | Rotary Die Cutter | Punching Machine |

|---|---|---|---|

| Nylon Velcro | ✅ | ✅ | ✅ |

| Polyester Velcro | ✅ | ✅ | ✅ |

| Adhesive – Backed | ❌ (heat risk) | ✅ (cold mode) | ✅ |

| Eco/Recycled Velcro | ✅ | ✅ | ✅ |

| Fire – Retardant Velcro | ✅ (adjustable heat) | ✅ | ✅ |

For medical – grade or electronics applications, we usually recommend cold – cutting or rotary die to prevent glue distortion and maintain dimensional accuracy.

For textile, packaging, or uniform applications, hot and cold linear cutters or rotary cutters with wide feed support are ideal.

What production goals should influence your choice?

Think in terms of output, labor, and flexibility. The right Velcro cutter doesn’t just work — it fits your growth strategy.

By evaluating your daily output targets, batch sizes, and SKU diversity, we can recommend the most cost – effective cutting solution.

Consider These Factors

| Goal | Recommended Machine |

|---|---|

| High daily volume | Rotary Die Cutter or HXN – RDC |

| Minimal labor | Automatic Feeding Hot/Cold Cutter |

| Quick shape changes | Punching Machine with custom dies |

| Small space operation | Compact Dot Cutter (tabletop) |

| Multi – SKU flexibility | Quick – swap die models |

| Adhesive safety | Cold – cutting or punch press |

Example: Multi – Sector OEM (Germany)

- Makes straps for PPE, Velcro dots for electronics, labels for packaging

- Installed:

- 1 Webbing Ribbon Cutter (for PPE)

- 1 Rotary Dot Cutter (for packaging + electronics)

- Result:

- Reduced waste by 80%

- Lowered labor needs by 60%

- Achieved ROI in 4 months

What customization support do we offer?

Off – the – shelf dies and cutters don’t fit every brand — we understand that.

Suzhou Haoxinhe offers full customization services, including rotary die creation, punch mold design, cutting width adjustment, and cold/hot mode switching.

What We Customize

- Die Shapes: Circles, rounded rectangles, logos

- Cutting Width: From 5mm to 150mm+

- Feed Type: Manual, semi – auto, full auto

- Material Compatibility Setup: Flame retardant, thick loop, eco Velcro

- Interface Language: Multilingual touchscreen UI

We also provide trial cutting demos, so you can see how the machine performs on your exact material before ordering.

Why choose Suzhou Haoxinhe for your Velcro cutting solutions?

You don’t just need a machine — you need a supplier who understands B2B workflows, timelines, and technical diversity.

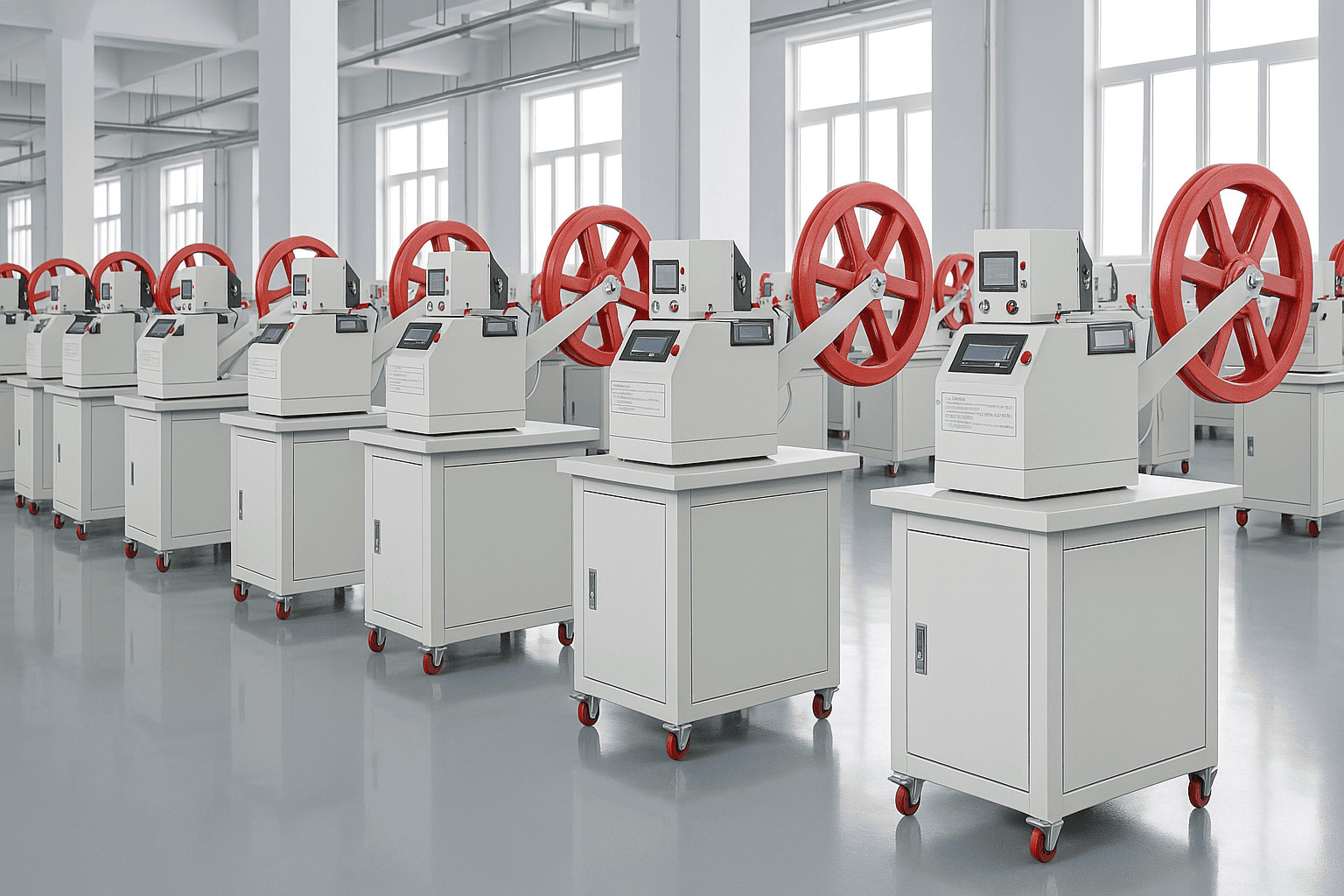

Suzhou Haoxinhe Electrical Equipment Co., Ltd. is a high – tech factory with 5 production lines, CE/ISO certifications, and a deep understanding of global manufacturing sectors.

What We Offer

- Factory – direct engineering and pricing

- Fast delivery (7–15 days worldwide)

- Multilingual technical sales team

- Custom tooling and die design

- Remote setup and training videos

- Spare parts and maintenance packages

We’ve helped clients across Europe, Southeast Asia, North America, and the Middle East upgrade their cutting capabilities for multi – sector success.

Conclusion

From electronics to uniforms to packaging, the right Velcro cutter boosts speed, precision, and ROI. We help you choose the machine that works — and scales — with your entire product line.

Insights

Multi – sector manufacturers need Velcro cutters that match diverse materials, shapes, and volumes. Suzhou Haoxinhe’s lineup includes hot/cold cutters, rotary die systems, and punching machines — all customizable and globally certified. With support for nylon, adhesive – backed, flame – retardant, and eco Velcro, our machines deliver high precision and reliable output for every industry.