Hook & Loop Dot Die Cutter for Promotional Material Production?

Tight deadlines. High volumes. Sharp presentation. Manual cutting just doesn’t cut it anymore.

Our hook & loop dot die cutter helps promotional material producers create thousands of clean, consistent Velcro dots — fast, efficient, and campaign-ready.

This article explains how this machine upgrades speed, quality, and flexibility for anyone producing kits, displays, packaging, or branded items with hook & loop fasteners.

Why do promotional materials use hook & loop dots?

Velcro makes things interactive. It opens, closes, sticks, and re-sticks — perfect for marketing campaigns that need attention and durability.

Hook & loop dots are used in promotional materials to create removable, repositionable parts that enhance usability and brand impact.

Real Use Cases

| Product | Hook & Loop Application |

|---|---|

| Event Kits | Modifiable folders, badge holders |

| POP Displays | Easy-to-assemble signage |

| Sample Boxes | Resealable packaging components |

| Educational Handouts | Interactive classroom tools |

| Corporate Gifts | Detachable parts or packaging |

Whether you’re shipping 500 sample kits or 50,000 giveaway packs, every dot has to match — in size, finish, and adhesive strength. And that’s why automation matters.

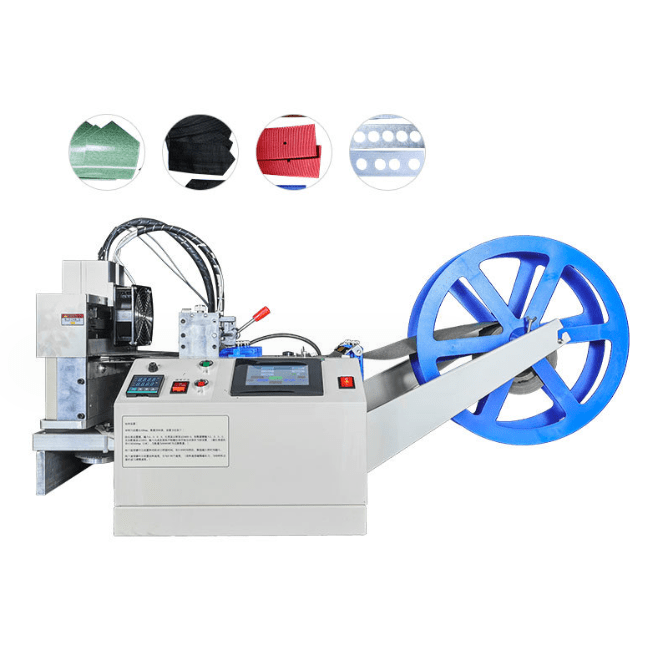

How does our dot die cutter work for promo production?

Manual dot cutting? Too slow. Laser cutting? Too expensive. Outsourcing? Too risky.

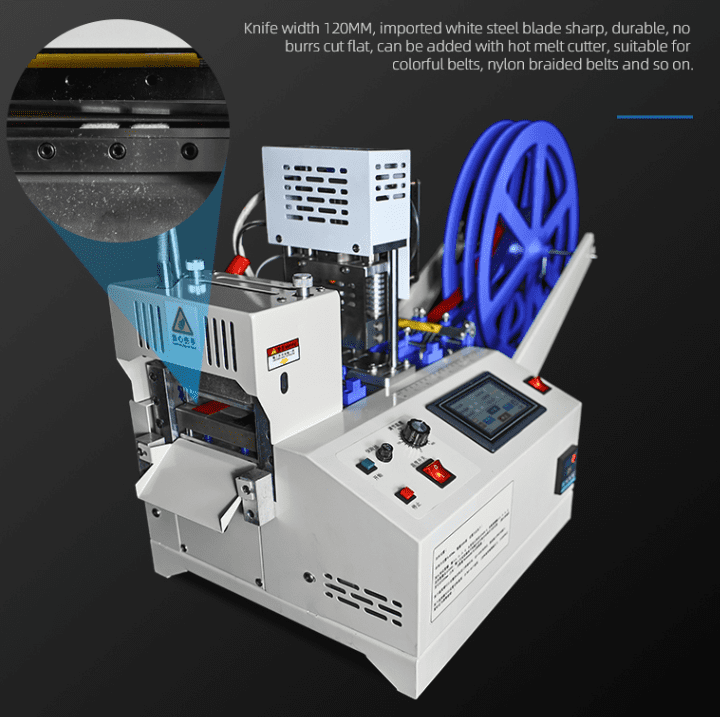

Our rotary hook & loop dot die cutter automates the cutting of circular Velcro dots, supporting fast turnaround and consistent output — even under tight campaign timelines.

How It Works

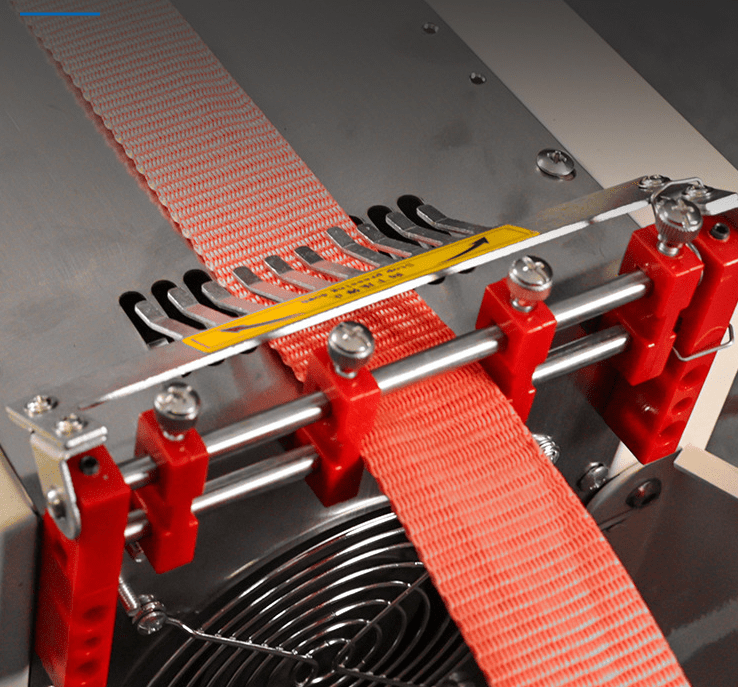

- Load hook & loop tape roll or sheet

- Feed into die cutter (auto or semi-auto)

- Die punches clean circles (multiple per stroke)

- Waste is auto-separated

- Finished dots roll or collect in bin

Our system works perfectly for adhesive-backed Velcro, which is common in marketing and promo use cases. Clean cutting = easy peeling = no frustrated end users.

What makes it ideal for promotional campaigns?

In marketing, timing is everything. You can’t afford slow output or inconsistent product quality.

The Haoxinhe Velcro dot die cutter increases daily output by up to 20x compared to manual cutting — all with repeatable accuracy and lower cost-per-piece.

Key Benefits

- Up to 10,000 dots/hour

- ±0.2mm accuracy

- Supports multiple dot sizes

- Custom die shapes available

- Easy operation — minimal training required

| Factor | Manual Cutting | Haoxinhe Die Cutter |

|---|---|---|

| Daily Output | 1,000–2,000 dots | 50,000+ dots |

| Operator Count | 2+ workers | 1 operator |

| Cut Consistency | Low | High |

| Downtime | High | Minimal |

| Waste Ratio | 10–15% | <3% |

Case Example: UK Branding Agency

- Needed 100,000 branded Velcro dots for interactive display stands

- Outsourcing quotes were too slow and expensive

- Switched to in-house with Haoxinhe dot die cutter:

- Completed job in 3 days

- Saved over £1,700 in labor and outsourcing

- Now offering Velcro dot branding as a new service

What sizes and shapes does the machine support?

Hook & loop dots aren’t one-size-fits-all. Some are tiny for subtle packaging, others oversized for signage or display panels.

Our die cutter supports various dot diameters and even custom shapes with quick-change die systems — perfect for changing product lines or campaign designs.

Popular Sizes

| Diameter | Typical Use |

|---|---|

| 10mm | Lightweight kits, brochure flaps |

| 15mm | POP displays, lightweight folders |

| 20mm | Sample boxes, document pouches |

| 25mm | Event kits, packaging closures |

| 30mm+ | Displays, signage, heavy inserts |

Custom Options

- Rounded rectangles

- Branded logos

- Star shapes or icons

- Layered dots with peel tabs

You tell us your vision — we build the die.

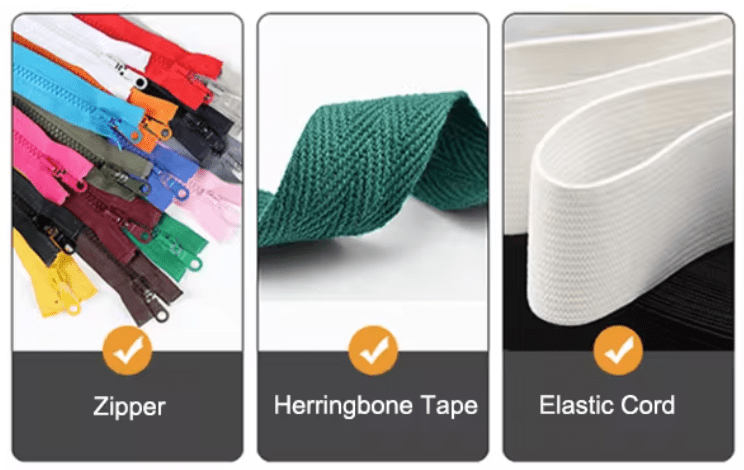

Which materials are supported?

Not all Velcro is equal. Some are soft loop, others rigid hook. Some come with strong adhesives, others flame retardant or eco-friendly backings.

Our machine is compatible with a wide range of hook & loop types, including sticky-backed, soft loop, and premium promotional-grade Velcro.

| Material Type | Supported? | Notes |

|---|---|---|

| Nylon Hook & Loop | ✅ | Durable, versatile |

| Polyester Velcro | ✅ | Lightweight, budget-friendly |

| Adhesive-Backed Velcro | ✅ | Cold-cutting prevents glue distortion |

| Colored Velcro | ✅ | Great for branding |

| Eco/Recycled Velcro | ✅ | Use adjustable pressure settings |

Our team will recommend the best pressure settings and die setup based on your exact tape type and promo format.

Why choose Suzhou Haoxinhe for promotional production machines?

You need a supplier who can deliver fast, speak your language, and handle last-minute projects with confidence.

Suzhou Haoxinhe Electrical Equipment Co., Ltd. is a full-service cutting equipment manufacturer, with 5 production lines and customers in 30+ countries.

What You Get With Us

- Factory-direct pricing

- Custom die production

- Fast shipping (7–15 days worldwide)

- Multilingual sales & service team

- After-sales training and remote support

We also produce:

- Webbing ribbon cutting machines

- Hot and cold Velcro cutting machines

- Edge banding and foam cutting machines

- Tube and wire cutting equipment

Our machines are already powering promotional production lines in Germany, Italy, Canada, and Singapore — delivering results that clients trust.

Conclusion

Our hook & loop dot die cutter is the perfect solution for promotional material makers who need fast, precise, and professional Velcro cutting at scale.

Insights

Promo product producers rely on Velcro dots for interactivity and convenience. Suzhou Haoxinhe’s hook & loop dot die cutter delivers 10,000+ cuts/hour, supports custom shapes, and works with sticky-backed Velcro — making it ideal for branded kits, packaging, and displays. It’s fast, reliable, and built for real campaign timelines.