Reducing Labor Costs with Automatic Velcro Dot Machines?

Cutting Velcro dots by hand wastes time, materials, and money — especially when orders grow fast.

An automatic Velcro dot machine reduces labor costs by up to 70% while boosting production speed and cutting accuracy.

Here’s how our machine helps factories, small and large, simplify dot production and turn overhead into profits.

Why is manual Velcro dot cutting inefficient?

It seems simple: cut some Velcro dots. But when you scale that across 10,000+ units a week, things get slow, inconsistent, and costly.

Manual Velcro dot cutting is time-consuming, labor-intensive, and error-prone — often requiring multiple workers to keep up with demand.

Common Problems with Manual Cutting

| Problem | Impact |

|---|---|

| Inconsistent Sizing | Affects product quality |

| Slow Production | Missed deadlines |

| Material Waste | Lower profit margins |

| Labor Dependency | Training + high turnover |

| Physical Strain | Increased worker fatigue |

Many clients in the apparel, toy, packaging, and uniform industries have told me they initially underestimated how much time and money manual cutting consumes.

That’s where Suzhou Haoxinhe’s automatic Velcro dot machines come in.

How does our machine reduce labor costs?

Labor is one of the biggest expenses in manufacturing. By automating Velcro dot cutting, you slash the need for manual labor on repetitive tasks.

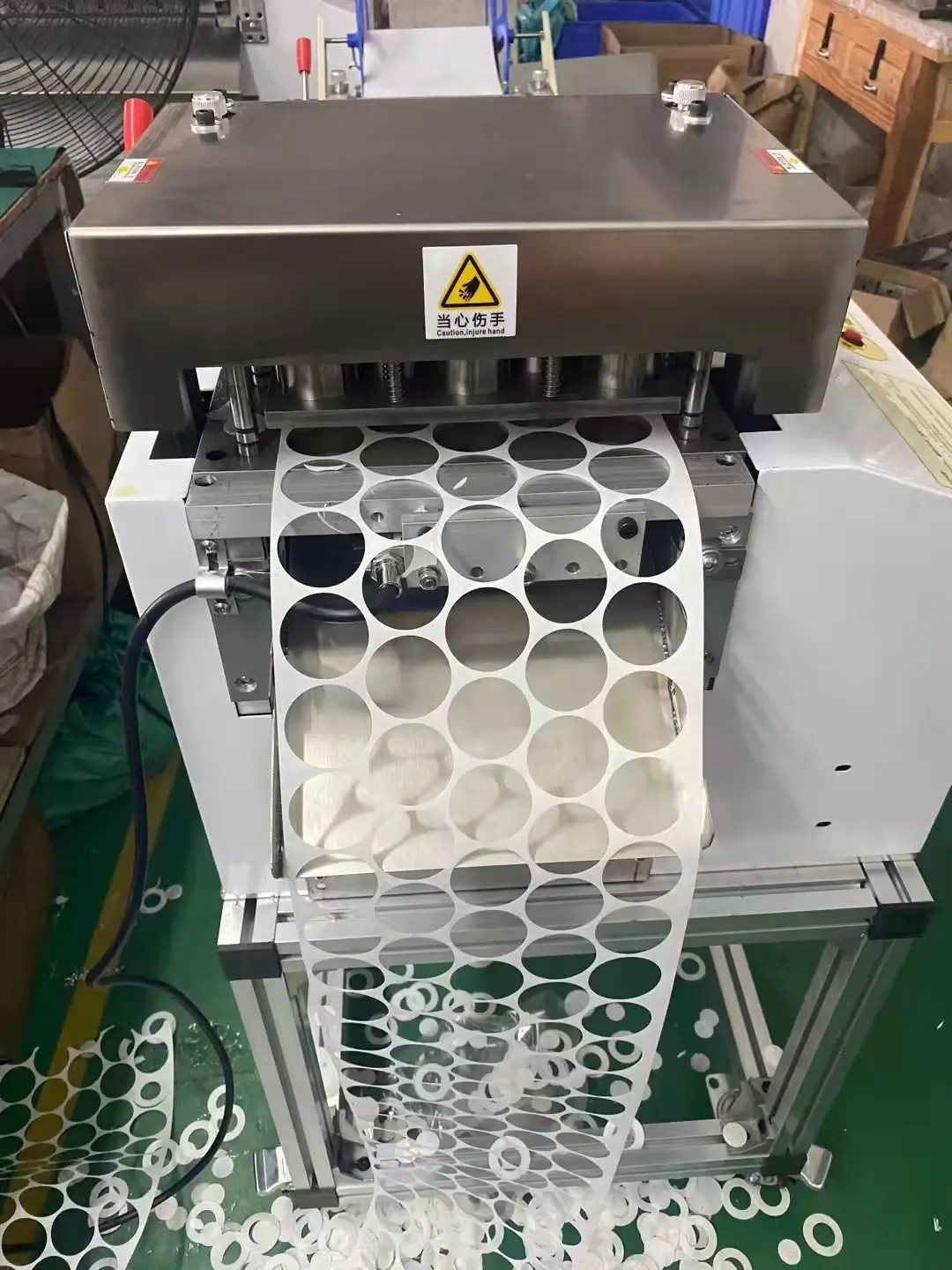

Our machine handles the entire cutting process — feeding, positioning, cutting, and separating — with minimal human input.

Key Features That Save Labor

- Automatic Feeding System: Roll-to-roll design eliminates manual material handling

- Rotary Die Cutting: Cuts 10,000+ dots/hour, with perfect shape every time

- Touchscreen Controls: Easy to train workers with minimal technical background

- Compact Setup: Only one operator needed to monitor — not cut

| Task | Manual Cutting | Haoxinhe Dot Machine |

|---|---|---|

| Loading & Feeding | Manual | Automatic |

| Cutting | Hand or punch | Rotary die |

| Accuracy Check | Visual, frequent | Built-in calibration |

| Operator Count | 2–3 workers | 1 part-time monitor |

Example: Uniform Patch Supplier (Canada)

- Manual labor: 3 workers, 6 hours/day, 5 days/week

- Labor cost: ~$3,000/month

- After automation:

- 1 part-time operator

- Saved over $2,000/month

- Production increased 5x

The ROI was achieved in just 4 months — and now they use those savings to reinvest in marketing and packaging upgrades.

Is it suitable for small factories too?

Automation isn’t just for big factories anymore. We design our machines with small workshops and startups in mind.

Our compact Velcro dot machine fits into tight spaces, requires standard power, and reduces the workload of small teams dramatically.

Designed for Compact Operations

Tabletop Size Options

Ideal for workshops, studios, or garage-based businessesSingle-Phase Power Supply

No industrial voltage requiredQuick Die Changes

Switch between dot sizes in under 5 minutesLow Training Curve

No engineering staff required to operate or maintain

| Business Type | Output Need | Recommended Model |

|---|---|---|

| Etsy-style brand | <5,000 dots/week | HXN-MINI |

| Local factory | 10,000–20,000 dots/week | HXN-RC100 |

| Medium-size exporter | 30,000+ dots/week | HXN-VDC |

We’ve worked with craft packaging brands in France, Montessori kit makers in Singapore, and uniform suppliers in Italy — all using our machines to streamline their dot cutting.

What other cost-saving benefits does the machine offer?

Labor is just one piece of the puzzle. Our machine also cuts costs by reducing waste, improving consistency, and speeding up production timelines.

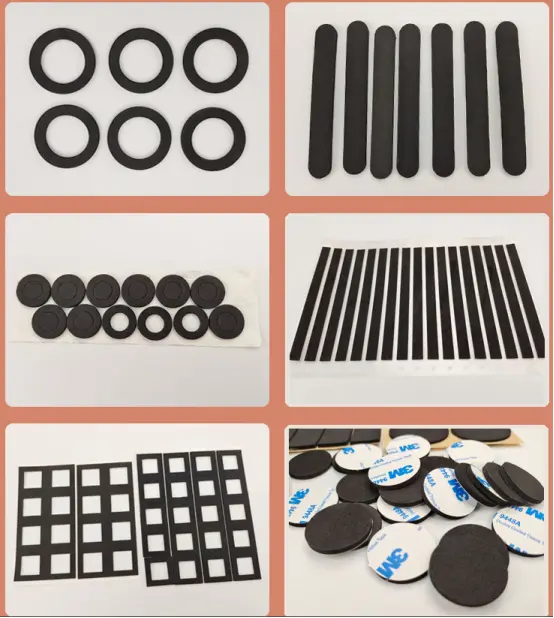

With ±0.2mm accuracy and minimal leftover material, our Velcro dot cutter helps you save on both raw materials and post-processing.

Secondary Cost-Saving Benefits

Reduced Waste

Clean cuts = less unusable edge materialFewer Reworks

Consistent sizes reduce rejected unitsLower Tooling Costs

One machine handles multiple sizes via quick-swap diesTime Saved = More Output

Less time spent per batch = more orders fulfilled

| Area | Manual Method | Haoxinhe Cutter |

|---|---|---|

| Dot Size Deviation | ±2mm | ±0.2mm |

| Rework Rate | High | Low |

| Setup Time | 20–30 min/day | <5 min/day |

| Waste Ratio | 15%+ | <3% |

This adds up — especially for high-volume factories trying to stay competitive in tight-margin industries.

Why choose Suzhou Haoxinhe?

We don’t just build machines — we build long-term solutions tailored to your production needs.

Suzhou Haoxinhe Electrical Equipment Co., Ltd. is a full-scale manufacturer with 5 production lines, exporting to over 30 countries worldwide.

What Sets Us Apart

- Direct Factory Pricing

No middlemen — maximize your margin - Multilingual Support

English, French, Chinese sales and tech team - Certified Machines

CE, ISO9001 ready for export and customs - Custom Die Support

Send us your desired dot shape — we’ll build the tool - Fast Delivery

7–15 days worldwide shipping

Our broader catalog includes:

- Webbing ribbon cutting machines

- Hot and cold cutting machines

- Rotary bevel die cutters

- Protective foam cutting machines

- PVC edge banding cutters

We’ve worked with small brands, government uniform suppliers, and global wholesalers — helping them automate smarter, not harder.

Conclusion

If you’re ready to cut labor costs without cutting corners, our automatic Velcro dot machine is the tool that transforms your production floor.

Insights

Factories still cutting Velcro dots by hand are losing time and money. Suzhou Haoxinhe’s automatic Velcro dot machines reduce labor needs by up to 70%, deliver ±0.2mm accuracy, and produce 10,000+ dots/hour. With compact models for small workshops and high-speed options for large-scale production, it’s the fastest way to improve efficiency and profitability in any hook and loop operation.