What is the best way to cut a PTFE sheet for gaskets?

PTFE is slippery, tough, and heat-resistant—but cutting it cleanly into gasket shapes can be frustrating without the right equipment.

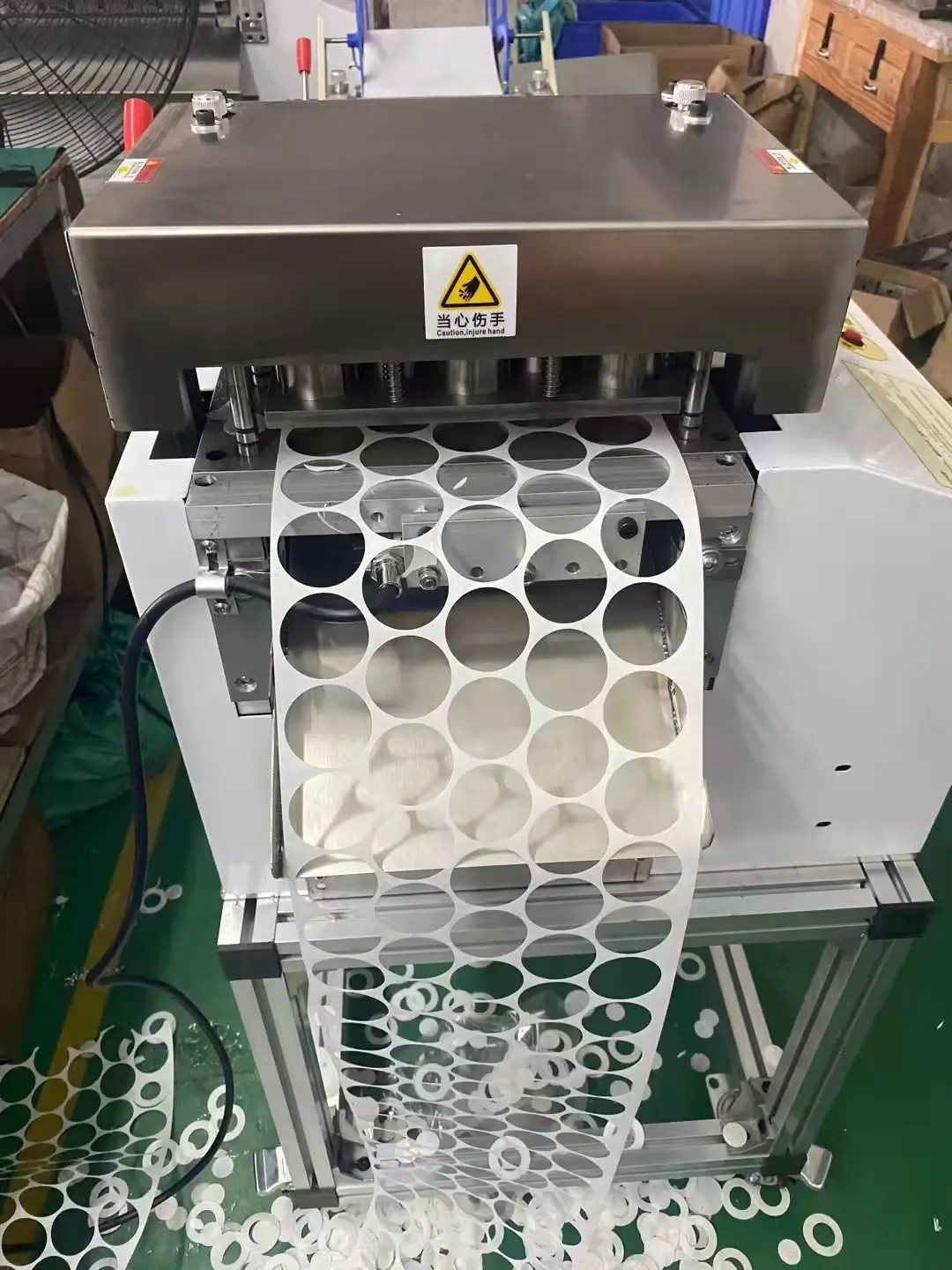

The best way to cut a PTFE sheet for gaskets is by using a high-precision knife cutting machine1, such as a webbing tape cutting machine2 or computer-controlled flatbed cutter designed for non-metallic materials.

If you’re still using blades or dies to cut PTFE, you’re likely facing frayed edges, warped cuts, and high scrap rates. Let’s explore the smarter solution: automated knife cutting machines tailored for PTFE.

Why is PTFE hard to cut accurately?

PTFE, or polytetrafluoroethylene, is highly durable—but also slippery and prone to deformation when cut with traditional tools.

PTFE is difficult to cut accurately due to its low friction, high toughness, and tendency to warp or stretch under blade pressure.

A Canadian client of mine once tried cutting PTFE manually for HVAC gasket applications. The result? Inconsistent dimensions and customer complaints due to leaks.

Common Cutting Issues with PTFE

| Problem | Cause | Risk |

|---|---|---|

| Warping | Pressure from dull blades | Gasket doesn’t fit |

| Frayed Edges | Inappropriate cutting angle | Seal failure |

| Melted Edges | Using high-temperature methods | Loss of shape and sealing ability |

That’s why we recommend cold, high-speed, precision-controlled knife cutting methods for PTFE gaskets.

What machine works best for PTFE gasket cutting?

Many cutting tools can handle rubber and foam, but PTFE needs something sharper and smarter.

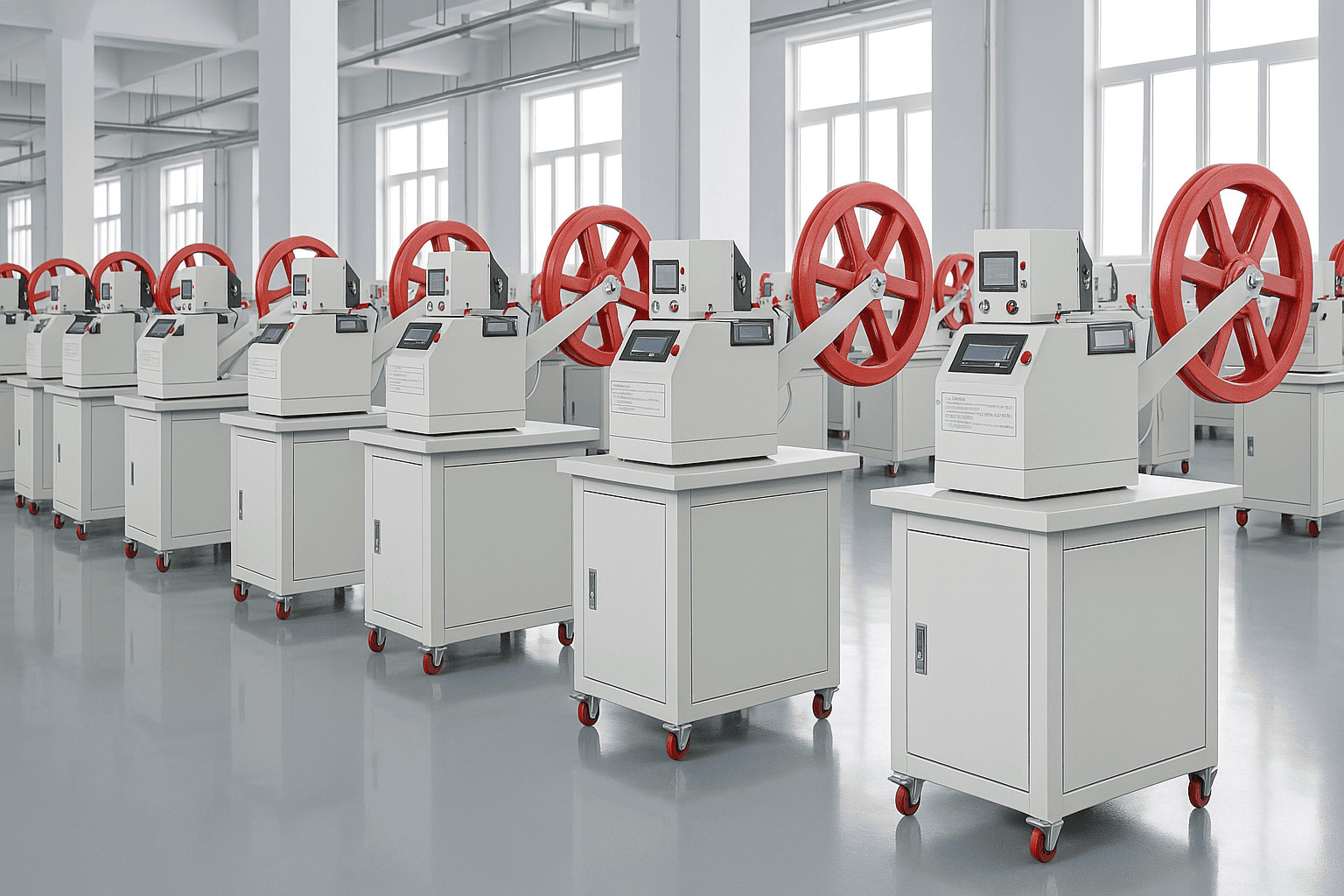

The best machines for PTFE gasket cutting are high-speed knife cutters like flatbed CNC cutting machines or customizable webbing ribbon cutting machines from Suzhou Haoxinhe.

We’ve helped multiple customers in Europe and North America switch to precision knife systems for PTFE. The difference in cut quality, edge finish, and repeatability is night and day.

Recommended Machines for PTFE

| Machine | Function | Why it Works |

|---|---|---|

| Computer Tube Cutting Machine | Programmable for curves | Accurate for complex PTFE gaskets |

| Webbing Tape Cutting Machine | Cold blade, high speed | No material distortion |

| Automatic Punching Cutting Machine | High batch volume | Great for repetitive PTFE shapes |

| Protective Foam Cutting Machine | Soft clamping system | Avoids PTFE surface deformation |

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we offer knife cutting machines that combine blade pressure, feed speed, and control systems to handle even slick PTFE surfaces with ease.

How to ensure clean cuts and prevent material waste?

PTFE isn’t just tough on blades—it’s expensive to waste.

To avoid waste and get clean cuts, use a CNC knife cutting machine3 with adjustable blade pressure, precision guides, and a no-slip feeding system.

Back when I worked with a buyer from Italy, his biggest issue was the 20% material loss per roll of PTFE. After testing samples on our rotary bevel cutting machine, he saw immediate savings and better edge quality.

Key Settings That Affect PTFE Cutting

- Blade Type: Use high-carbon steel or ceramic blades.

- Cutting Speed: Slow and steady prevents edge distortion.

- Pressure Control: Adjustable for thicknesses from 0.5mm to 6mm.

- Feeding System: Anti-slip rollers are critical for PTFE.

Tips to Reduce Waste

- Use Sample Cutting Mode before full runs.

- Replace blades regularly—dull knives cause tearing.

- Use clamping guides to keep PTFE flat during cuts.

Suzhou Haoxinhe’s machines come with sample cutting functions and adjustable parameters, which help clients from chemical, pharma, and electronics industries produce consistent PTFE gaskets.

Can PTFE sheets be laser-cut instead?

Laser sounds modern—but PTFE doesn’t like heat.

No, PTFE should not be laser-cut because it emits toxic fumes and the edges may char or deform under heat.

One client of ours in Singapore attempted laser cutting PTFE to save time, only to end up replacing half their stock due to yellowed, melted edges. Worse, they had to install costly ventilation to handle fumes.

Why Laser Is Not Suitable for PTFE

| Issue | Result |

|---|---|

| Fume Emission | Releases toxic gases |

| Heat Sensitivity | Edges melt or char |

| Inconsistent Cuts | Hard to calibrate laser for PTFE thickness |

Stick to knife-based systems when cutting PTFE. Machines like our high-speed trademark cutting machine use controlled blade pressure and can handle complex gasket profiles without harming material integrity.

Conclusion

Knife cutting machines are the best option for clean, precise, and safe PTFE gasket production—no heat, no fumes, no waste.

INSIGHT:

To cut PTFE gasket sheets accurately and safely, use precision knife cutting machines like Suzhou Haoxinhe’s webbing tape cutting machine2 or automatic punching cutting machine. These tools prevent material distortion, minimize waste, and produce clean gasket shapes for demanding industrial applications.

Explore this link to understand how high-precision knife cutting machines can enhance your PTFE cutting process, ensuring clean and accurate cuts. ↩

Discover the advantages of webbing tape cutting machines for PTFE, including their ability to prevent material distortion and ensure quality cuts. ↩ ↩

Learn about CNC knife cutting machines and their benefits for cutting PTFE, including precision and reduced waste. ↩