How Do You Make a Clean Hole in Nylon Webbing Without Fraying?

[^1]](https://hxcuttingmachine.com/wp-content/uploads/2025/03/%E5%90%84%E7%A7%8D%E5%8F%AF%E4%BB%A5%E5%88%87%E7%9A%84%E5%BD%A2%E7%8A%B6-removebg-preview_%E5%89%AF%E6%9C%AC.png)

I once lost a client because the holes in their nylon straps frayed after just two uses. That was the wake-up call that changed everything in my production line.

To make a clean hole in nylon webbing1, use a heated punch2 that melts and seals the fibers as it cuts, ensuring no fraying and a smooth finish.

Let me show you the exact method and tools I use in our factory to create strong, professional-grade holes in webbing—fast and clean.

Why Is It So Hard to Punch a Clean Hole in Nylon Webbing?

Nylon webbing is thermoplastic. When you cut or punch it without heat, the fibers break apart, creating weak points. Even a sharp punch doesn’t stop the edges from fraying later.

A clean hole in nylon webbing1 depends on using heat and pressure together so the edges melt into a sealed, durable ring.

Typical Issues Without the Right Tool

| Problem | Cause | Result |

|---|---|---|

| Frayed Edges | Cold punch or scissor cut | Unravels over time |

| Misshaped Holes | Uneven manual pressure | Inconsistent hole sizes |

| Burned Edges | Using open flame | Melts nylon too much or unevenly |

If your application involves load-bearing straps, outdoor gear, or harnesses, these flaws become real safety risks. That’s why our clients now trust Suzhou Haoxinhe Electrical Equipment Co., Ltd. for clean, sealed punching machines.

What’s the Best Tool to Create a Clean Hole in Nylon Webbing?

I’ve tried them all—scissors, cold punches, handheld torch tips. Only one method gives clean, repeatable results.

The best tool for making clean holes in nylon webbing is a heated hole punch or a hot die cutter that combines heat with punching force.

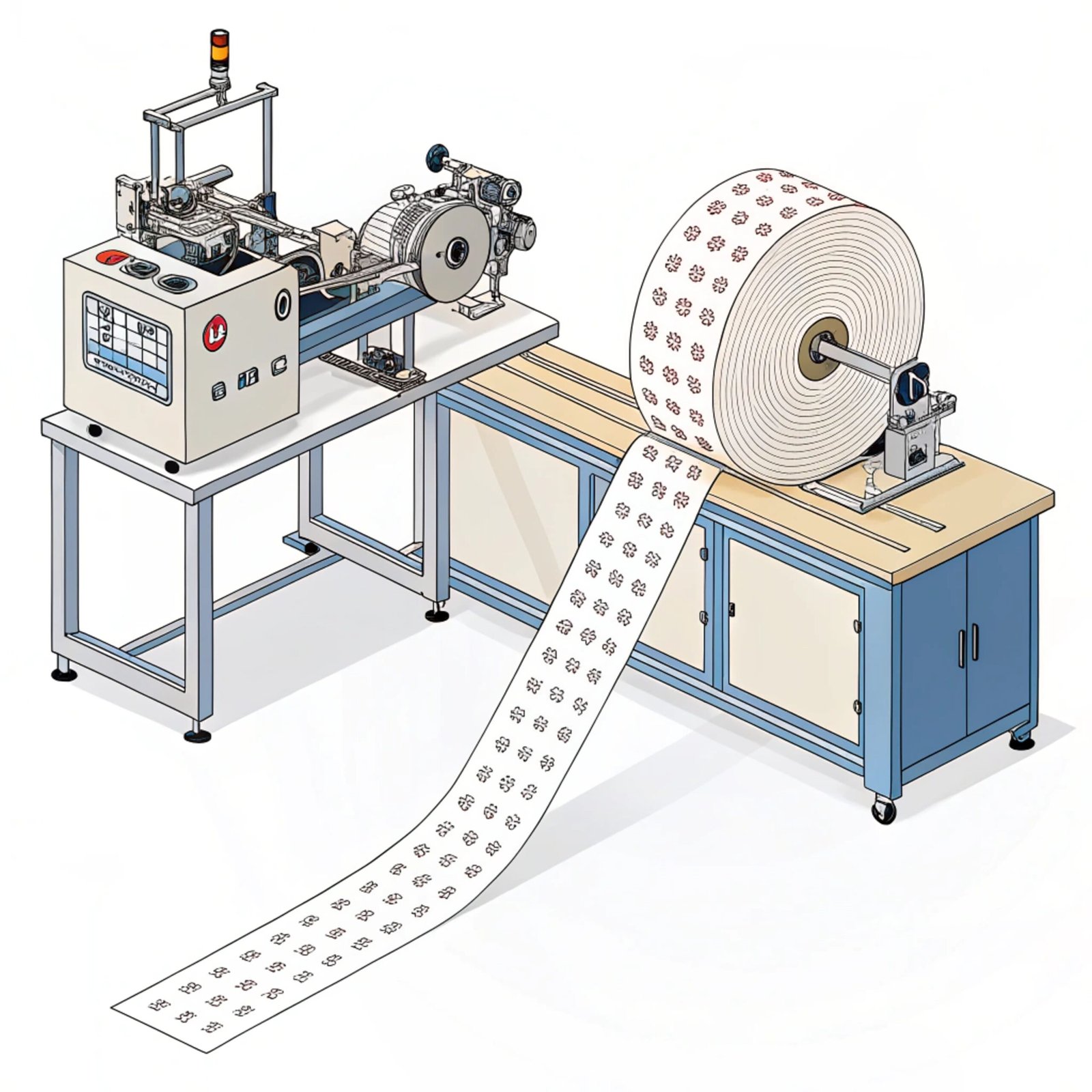

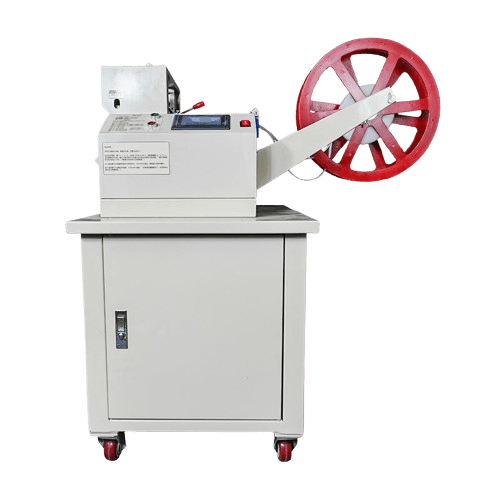

Recommended Machines from Our Production Line

| Machine Name | Key Feature | Material Suitability |

|---|---|---|

| Automatic Punching Cutting Machine | CNC-controlled hot punch + sealing | Webbing, PVC, films |

| Round Shape Cutting Machine | Creates sealed circular holes | Nylon, polyester straps |

| Webbing Ribbon Cutting Machine | Prepares ends + adds holes simultaneously | Flat webbing rolls |

| Rotary Bevel Cutting Machine | Adds angled edge and sealed hole combo | Load-bearing textile strips |

These machines are already in use by our buyers in Canada, France, Singapore, and Germany. They’re fully customizable—hole size, spacing, speed—all tailored to your webbing spec.

Step-by-Step Guide: Making a Clean Hole in Nylon Webbing

In my own workshop, this is the exact process my team follows to ensure every strap passes quality inspection—clean hole, zero fray.

Use a heated punch on a clamped webbing strip, apply steady pressure, and inspect for sealed edges immediately after.

The 6-Step Process

Cut the Webbing to Size

Use our webbing ribbon cutting machine for precise, sealed edges.Preheat the Punch

Heat the punch tool to 260–280°C depending on webbing thickness.Align the Material

Secure the strap on a metal plate or jig to ensure no movement.Punch Steadily

Lower the heated punch through the nylon using firm, even pressure.Inspect the Hole

Look for fully sealed edges—no white fibers, no black burn marks.Repeat or Switch to Auto

For 100+ straps, load into automatic punching cutting machine3 for batch processing.

How to Maintain a Clean Punch Over Time?

The cleaner your tool, the cleaner your holes. That’s one thing I’ve learned after servicing hundreds of machines for international clients.

Regularly clean and calibrate your heated punch2, check for die wear, and adjust temperature to avoid overheating or buildup.

Maintenance Tips

| Action | Frequency | Why It Helps |

|---|---|---|

| Clean Punch Tip | After every 100 pieces | Prevents burnt nylon residue |

| Check Temperature | Daily | Avoids over-melting or under-sealing |

| Replace Punch Die | Monthly (high volume) | Ensures clean, round hole edges |

| Lubricate Moving Parts | Weekly | Keeps machine punching evenly |

If you’re unsure, we offer remote maintenance guidance and supply spare parts globally.

Conclusion

Making a clean hole in nylon webbing1 is simple—when you use the right heated punch2 and follow a controlled process. No more fraying, no more waste.

Insights

To make a clean hole in nylon webbing1, use a heated punch2 that seals edges as it cuts. Machines like Suzhou Haoxinhe’s round shape cutting machine and automatic punching cutting machine3 deliver consistent, fray-free results for industrial use.

Learn effective techniques and tools to create clean holes in nylon webbing, ensuring durability and safety in your projects. ↩ ↩ ↩ ↩

Explore this link to understand the technology behind heated punches and how they ensure clean, fray-free holes in nylon webbing. ↩ ↩ ↩ ↩

Discover the advantages of automatic punching machines for efficiency and precision in creating clean holes in nylon webbing. ↩ ↩