What’s the Best Hole Punch for Webbing and Why Use a Hot Punch?

I used to think all hole punches worked the same—until my webbing started fraying, melting unevenly, or just tearing apart under pressure.

The best hole punch for webbing is a hot hole punch that seals the edges while cutting, preventing fraying and ensuring a clean, professional finish.

This guide explains exactly why a hot punch is better, what models are worth your time, and how I integrated these tools into my factory production lines.

Why Is a Hot Hole Punch Better Than a Standard Punch?

Using a cold punch might be faster—but it’s not cleaner. Nylon, polyester, and other synthetic webbings melt, not snap. Cold cuts lead to frayed edges and weak points.

Hot hole punches melt and seal the fibers as they pierce the webbing, leaving smooth, durable holes that won’t unravel under tension.

Common Problems with Cold Punching

| Problem | Cause | Result |

|---|---|---|

| Fraying Edges | Raw fiber ends left exposed | Weakens structural integrity |

| Deformation | Uneven pressure distribution | Misshaped holes |

| Melting After Punching | Using a lighter to seal manually | Inconsistent and dangerous process |

In my factory, I replaced cold punch setups with automated hot hole punches from Suzhou Haoxinhe Electrical Equipment Co., Ltd. The improvement in quality and time saved was immediate.

What Features Should the Best Hole Punch for Webbing Have?

There are many tools out there that claim to work. But I’ve learned the hard way—what works for cardboard or leather won’t necessarily work for synthetic webbing.

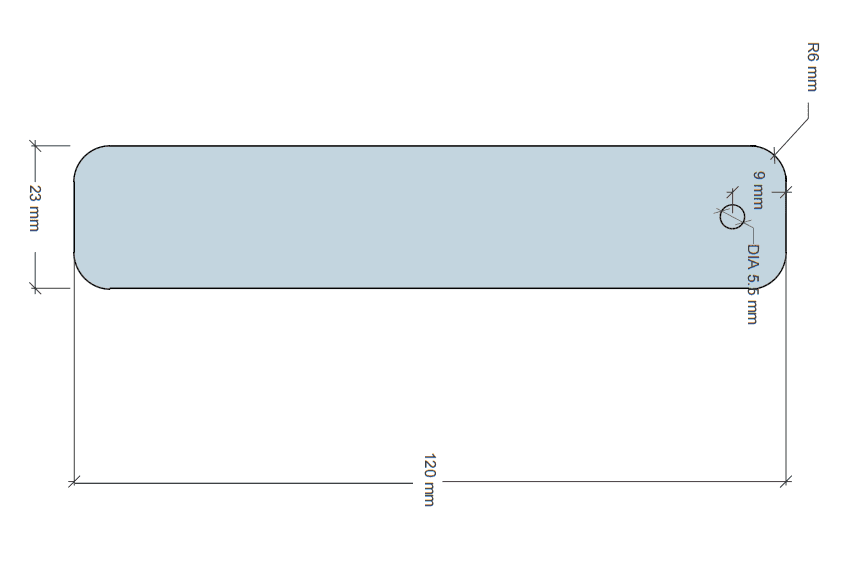

The best hole punch for webbing should offer controlled heat, adjustable pressure, accurate alignment, and customizable die sizes.

Key Features Checklist

| Feature | Why It Matters |

|---|---|

| Temperature Control | Prevents overheating or burning |

| Customizable Dies | Accommodates different hole diameters |

| Pressure Adjustment | Ensures clean cut-through without crushing fibers |

| Stable Base/Clamp | Prevents slipping and ensures clean repeatability |

| Automation Options | Useful for high-volume production |

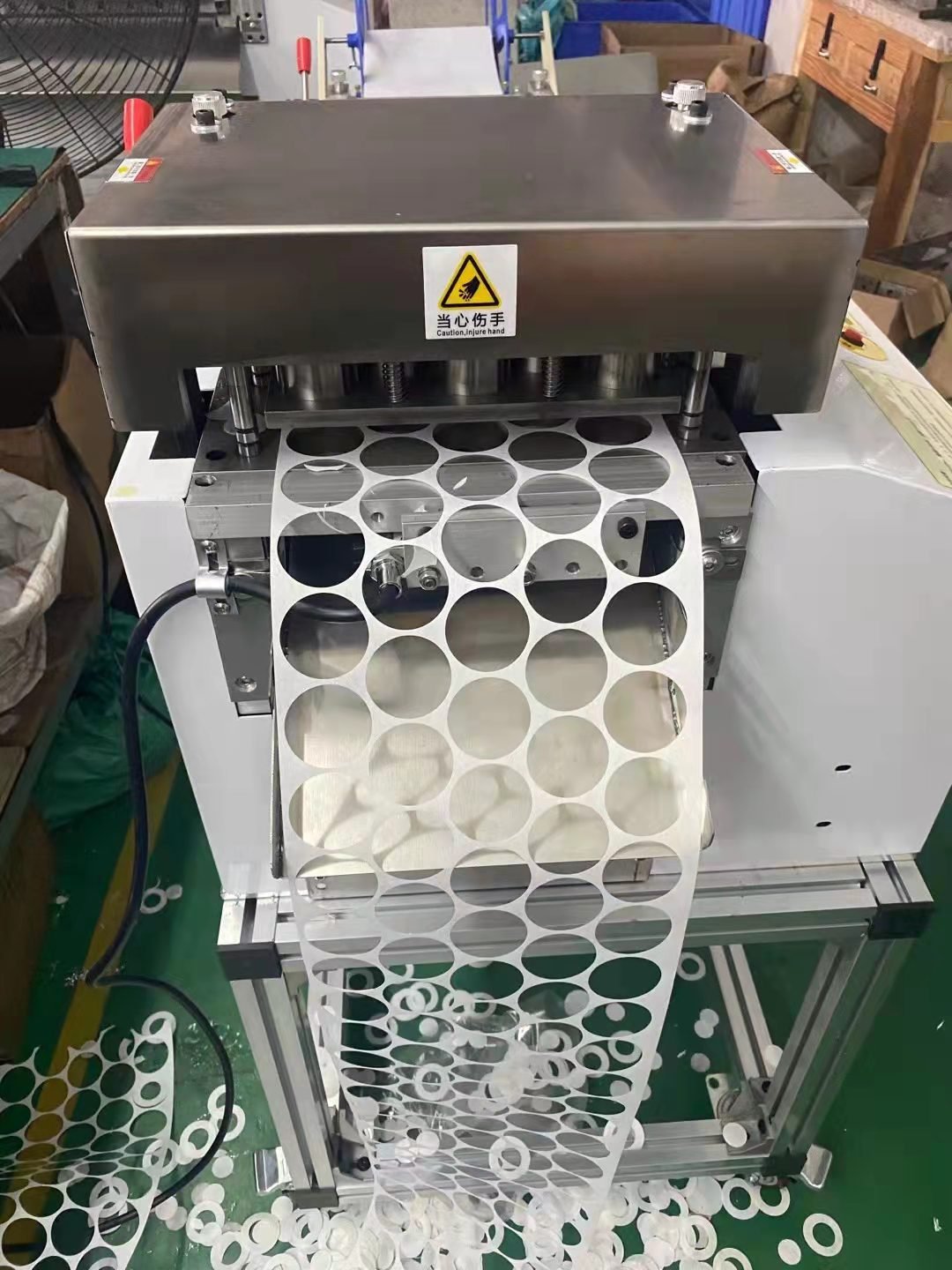

I personally recommend the automatic punching cutting machine by Suzhou Haoxinhe. It comes with temperature control, punch head customization, and CNC alignment for multi-hole patterns.

Other top picks from our product line:

- Round shape cutting machine – perfect for circular, sealed holes.

- Rotary bevel cutting machine – combines angle and heat precision.

- Webbing ribbon cutting machine – cuts and seals ends and holes in one go.

How to Use a Hot Hole Punch Correctly?

I’ve had buyers burn through expensive materials by skipping key setup steps. You don’t just plug and punch. You prep, align, and seal properly.

To use a hot hole punch correctly, always preheat the tool, secure the webbing in place, and use slow, firm pressure to ensure clean sealing.

Step-by-Step Guide (Manual Use)

- Preheat Punch Tip – Wait until the set temperature is reached.

- Position Webbing on Metal Base – Use a non-flammable, stable surface.

- Secure Alignment – For repeat holes, mark or use a guide.

- Punch Firmly and Steadily – Don’t rush the punch.

- Cool and Inspect – Check for clean edges and complete seal.

For batch work, I rely on programmable automatic machines. These use a preloaded pattern to punch 10–100 holes at once with uniform precision.

Which Hot Hole Punch Machines Are Best for Different Industries?

Different industries, different priorities. Some care about aesthetics, others about load-bearing strength. That’s why I always ask clients: What’s your webbing for?

From safety harnesses to chemical packaging, the best hot hole punch for your factory depends on volume, material type, and required finish.

Matching Machine to Application

| Industry | Recommended Machine | Reason |

|---|---|---|

| Outdoor Gear (Straps) | Webbing ribbon cutting + hot punch combo | Durable seal, zero fray |

| HVAC and Labs | PVC Edge Banding or Foam Cutting Machines | Clean finish, hygiene compliance |

| Printing & Pharma | Automatic Punching Cutting Machine | High-speed precision, customizable holes |

| Safety Equipment | Rotary Bevel Cutting Machine | Strong sealed holes at load points |

Our clients from Germany, Canada, and Singapore often opt for fully automatic solutions. They value the speed, repeatability, and integrated QC features. If you’re still using handheld tools—it’s time to level up.

Conclusion

A hot hole punch delivers the cleanest, strongest results when working with nylon or synthetic webbing.

Insights

The best hole punch for webbing is a hot hole punch that melts and seals fibers during cutting. For bulk manufacturing, Suzhou Haoxinhe’s automatic punching machines provide high-speed, fray-free precision ideal for industrial use.