How to Poke a Hole in Nylon and Can You Use Rivets on Nylon Webbing?

Ever tried poking a hole in nylon—only to end up with a melted mess or frayed fabric? It happens more than you’d think, especially with synthetic materials like webbing or straps.

To poke a hole in nylon cleanly, use a heated punch1 or a soldering iron with a sharp tip. This melts the edges while cutting, preventing fraying.

Now, what if you want to go a step further and install rivets for reinforcement? Yes—you can, but there’s a method to doing it right.

How to Poke a Hole in Nylon Without Fraying?

Nylon isn’t like cotton or canvas—it melts, stretches, and frays if handled wrong.

The cleanest way to poke a hole in nylon is to use heat, either with a heated hole punch, soldering tool, or a hot nail. This seals the fibers instantly.

Step-by-step Guide to Heat-Punch Nylon

Whether it’s for nylon webbing2, PVC edge banding, or protective foam, this method is universal.

Tools You Can Use:

- Heated hole punch (preferred)

- Soldering iron with narrow tip

- Butane-heated pin or nail

- Leather punch (if reinforced)

Instructions:

- Mark the hole location using chalk or marker.

- Preheat the tool until it’s hot enough to melt nylon.

- Press gently into the material; don’t force it.

- Let cool for a few seconds.

- (Optional) Insert a grommet or rivet if reinforcement is needed.

At Suzhou Haoxinhe, we’ve tested all of these methods—especially for clients who don’t need full automation but want reliable edge integrity.

Why Heat Beats Manual Cutting

| Method | Fray Risk | Speed | Cleanliness |

|---|---|---|---|

| Scissors or knife | High | Fast | Poor |

| Leather punch | Medium | Good | Frays on edge |

| Heated punch | Low | Good | Very Clean |

In our factory, when we work with automatic punching cutting machine3s, we always recommend integrating a heat-punch module if nylon is involved.

Can You Use Rivets on Nylon Webbing?

[^2] with rivets for reinforcement](https://hxcuttingmachine.com/wp-content/uploads/2025/03/3-3.png)

Absolutely. Rivets not only work with nylon—they can also strengthen your project and prevent hole expansion under load.

Yes, you can use rivets on nylon webbing2. Just ensure the hole is heat-sealed and you use the correct rivet size and backing washer for secure attachment.

Best Practices for Riveting Nylon Webbing

This advice is based on hundreds of customer applications in HVAC, chemical packaging, and manufacturing industries using our webbing processing machines.

Step-by-step:

- Poke the hole with heat (as explained above).

- Insert the rivet through the hole.

- Use backing washers to distribute the force.

- Press using a rivet setter or press machine.

- (Optional) Add a grommet for extra strength.

Best Rivet Types for Nylon Webbing

| Rivet Type | Application | Notes |

|---|---|---|

| Aluminum | Lightweight bags, straps | Won’t rust, easy to press |

| Brass/Nickel | Heavy-duty outdoor gear | Corrosion-resistant |

| Plastic | Lightweight, decorative items | Lower strength |

| Steel | Load-bearing components | Requires strong setting tools |

When We Recommend Rivets to Clients

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we often work with manufacturers needing riveted webbing in products like:

- Luggage or tactical bags

- Lab harnesses

- Industrial foam packaging with straps

- HVAC duct straps

We’ve even built custom cutting machines with rivet-positioning guides to speed up production and improve hole alignment.

Bonus Tip: Want Fray-Free Results Every Time?

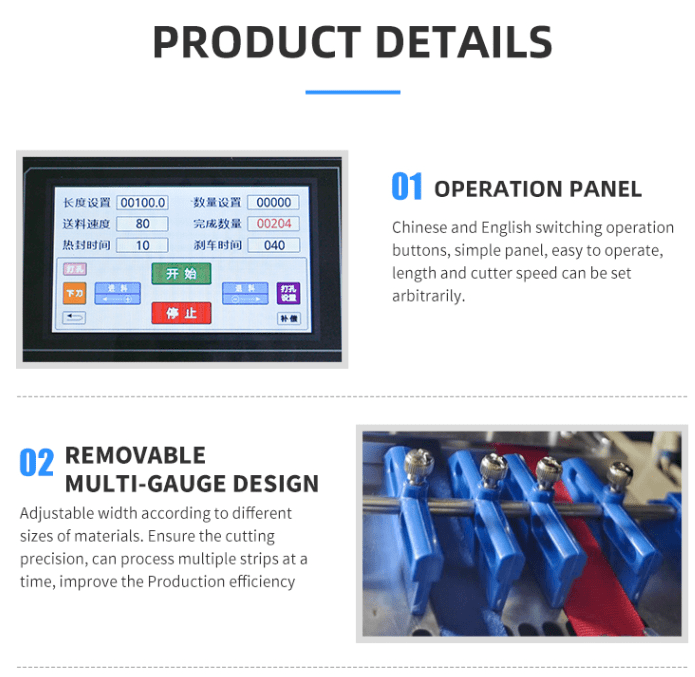

Consider investing in an automatic punching cutting machine3 that includes:

- Adjustable temperature punch heads

- Multi-position punching (custom distances)

- Real-time webbing alignment control

Many of our clients from Canada, Germany, and Singapore use these for materials like:

- Webbing ribbon

- PVC edge banding

- Bubble wrap

- Protective foam

Conclusion

You can poke holes in nylon and install rivets if you apply heat and use the right tools. For industrial production, automated heated punching systems are the best choice.

Insights

To poke a hole in nylon without fraying, use a heated punch or soldering iron. This method melts the fibers for clean results. Rivets can be used on nylon webbing when the holes are properly heat-sealed and reinforced with washers. At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we offer customizable webbing tape cutting machines and automatic punching cutting systems that streamline hole-making and rivet-ready processing for industrial materials like nylon, PVC edge banding, and foam. Our machines are trusted by global manufacturers who need precision, speed, and long-term reliability.

Meta Description

Learn how to poke holes in nylon without fraying and how to install rivets on nylon webbing. Suzhou Haoxinhe offers heated punching and cutting machine solutions for industrial materials.

Discover how a heated punch can provide clean cuts in nylon, preventing fraying and ensuring a professional finish in your projects. ↩

Explore this resource to understand the best practices for reinforcing nylon webbing with rivets, ensuring durability and strength in your projects. ↩ ↩

Learn about the advantages of automatic punching cutting machines, which enhance efficiency and precision in cutting nylon and other materials. ↩ ↩