How to Punch Holes in Nylon Webbing Without Damaging It?

Punching holes in nylon webbing seems simple—until the holes fray, melt unevenly, or ruin your materials. Most people try and fail before finding the right tools and methods.

The best way to punch clean, strong holes in nylon webbing is by using a heated hole punch or a rotary punch designed specifically for synthetic webbing. This prevents fraying and strengthens the hole edges.

There’s a right way to do it—and dozens of wrong ways. I’ve worked with webbing materials for years, and here’s the tested method that works every time.

What tools can punch holes in nylon webbing cleanly?

Nylon webbing is strong, durable—and tricky. The wrong punch tool can destroy it fast.

To punch holes in nylon webbing without fraying or damaging it, use a hot punch tool, a rotary punch, or a heated grommet press.

Why heat matters for punching nylon

Nylon melts instead of tearing when exposed to heat. If you use a standard metal punch, the friction can tear the fibers rather than seal them. That’s why heated tools are game-changers.

Here are three main options:

| Tool Type | Pros | Cons |

|---|---|---|

| Heated hole punch | Seals edges, no fraying, long-lasting | Requires power source |

| Rotary hole punch (non-heated) | Easy to use, manual | May fray nylon, not suitable for thick webbing |

| Grommet press with heat | Strong results, adds reinforcement | Bulkier setup, pricier |

My experience with hole punching tools

In my factory at Suzhou Haoxinhe Electrical Equipment Co., Ltd., we produce webbing tape cutting machines and often customize them with punching modules. I’ve tested all three tool types on webbing of different thicknesses and coating types—PVC, PU, plain nylon—and here’s what I found:

- Heated hole punches consistently give the cleanest results.

- Manual punches are faster for low-volume tasks but risk fraying.

- Grommet presses are best when you want a reinforced hole (e.g., straps, tie-downs).

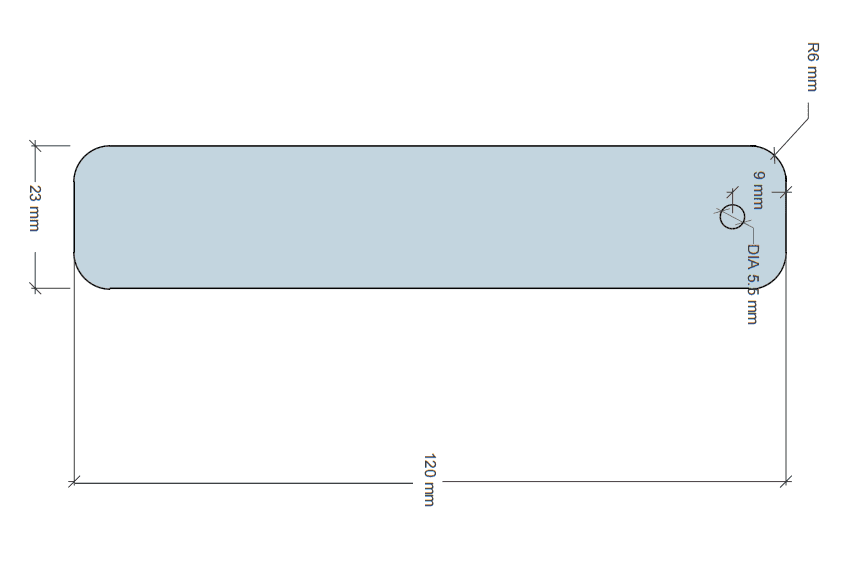

Pro tip: match punch size to grommet

If you’re planning to insert a grommet or eyelet, always use a punch that matches the inner diameter of your grommet exactly. A mismatch can cause slipping or webbing failure under load.

What’s the best method to punch holes without fraying?

Many people punch the hole first and try to melt the edges after. That’s the mistake.

The best method is to use a heated punch tool that melts and punches at the same time—this seals the nylon instantly.

Step-by-step method I use in production

Whether I’m customizing with our automatic punching cutting machine or working manually, here’s how I do it:

Tools you need:

- Heated punch (electric or butane-powered)

- Cutting board or metal surface

- Measuring tape or template

- Heat-resistant gloves (optional but safe)

Process:

- Mark the hole position. Use chalk or fabric marker.

- Align the punch. Place the webbing on a flat, heat-safe surface.

- Press down firmly. Let the heat do the work. Don’t rush.

- Lift and inspect. You should see a clean, sealed hole.

- Optional: Add a grommet. If extra strength is needed.

This method works especially well for:

- Seatbelt-style webbing

- Outdoor gear straps

- Custom luggage or harness components

At Suzhou Haoxinhe, many of our customers in HVAC, packaging, and automotive industries prefer this method because it’s fast, scalable, and minimizes defects.

How do industrial factories punch holes in webbing?

If you’ve ever wondered how top factories punch thousands of webbing holes daily, here’s the secret.

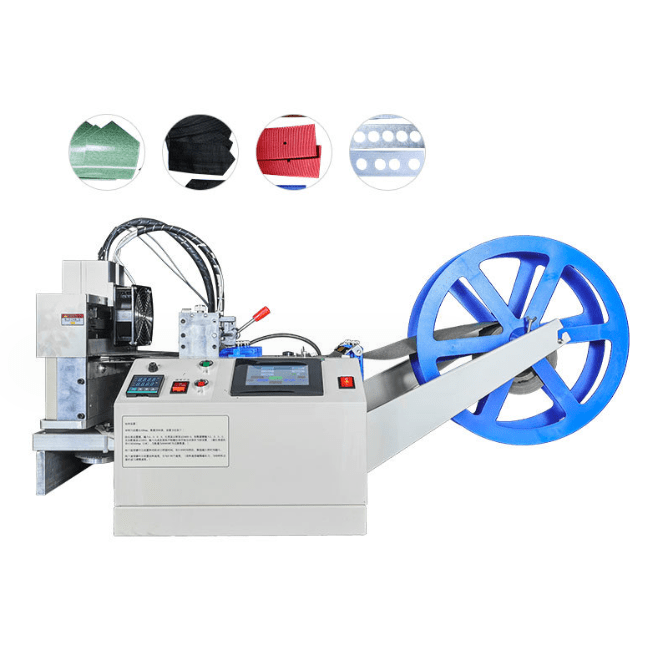

Factories use CNC-controlled cutting and punching machines, often integrating hot punching with automated feeding and cutting systems.

Inside our webbing hole punch production

We manufacture advanced equipment like:

- Automatic punching cutting machine

- High-speed trademark cutting machine with punch

- Rotary bevel cutting machine with customized molds

Our customers include:

- Printing industry using custom webbing labels

- Chemical labs that need ultra-precise tubing holes

- Pharmaceutical packaging lines with specific webbing designs

By integrating punching with cutting, we reduce waste and improve speed. One setup can punch and cut PVC edge banding, bubble wrap, or protective foam—each with different temperature and pressure profiles.

Benefits of automated punching

| Benefit | Why it matters |

|---|---|

| Precision | Ensures repeatable hole placement |

| Speed | Up to 150 cuts/min with punch |

| Clean edges | Heated systems prevent fray |

| Versatility | Works on tubular, flat, or round webbing |

Conclusion

Punching clean holes in nylon webbing is easy—if you use the right tools and methods.

Insights

To punch holes in nylon webbing without damage, use a heated hole punch that melts and seals the edges in one step. This prevents fraying, increases durability, and ensures professional results. Industrial setups often combine cutting and punching in one automated machine for speed and precision. Suzhou Haoxinhe Electrical Equipment Co., Ltd. offers customizable solutions for webbing tape cutting and punching, helping manufacturers across industries improve efficiency and quality.