What is an Automatic Nylon Cutting Machine and How Does It Help Improve Production?

Cutting nylon manually leads to frayed edges, wasted material, and low cutting speed. That hurts your production efficiency and brand quality.

An automatic nylon cutting machine is a programmable system designed to cut nylon webbing, tape, fabric, or straps quickly, precisely, and without fraying.

If your factory deals with synthetic materials, this machine can boost your output and reduce costs.

What Does an Automatic Nylon Cutting Machine Do?

Nylon is strong but slippery. It stretches slightly under tension and frays when cut. Manual cutting can’t guarantee consistent lengths or clean edges.

An automatic nylon cutting machine feeds, measures, and cuts nylon-based materials using a hot knife or cold blade, depending on the application.

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., our machines are used to cut:

- Nylon straps

- Nylon webbing

- Nylon tapes and belts

- Woven nylon ribbon

- Nylon loops and bands

This machine is a top choice for industries like:

- Outdoor gear manufacturing

- Sports equipment production

- Automotive parts

- Packaging and strapping systems

- Apparel accessories

Key Features of Our Nylon Cutting Machine

| Feature | Description |

|---|---|

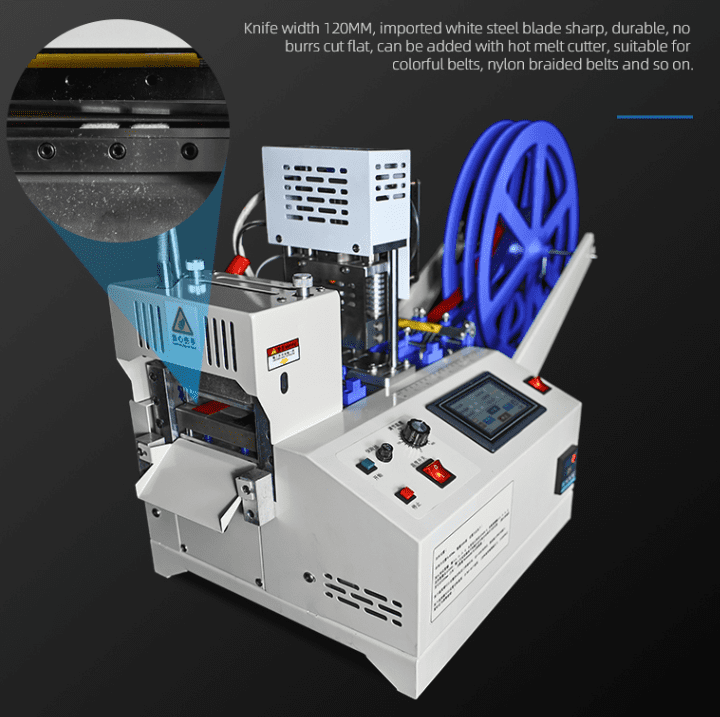

| Hot Knife Blade | Melts and seals nylon edges to prevent fraying |

| Servo Motor Feeding | Ensures high-speed and accurate length cuts |

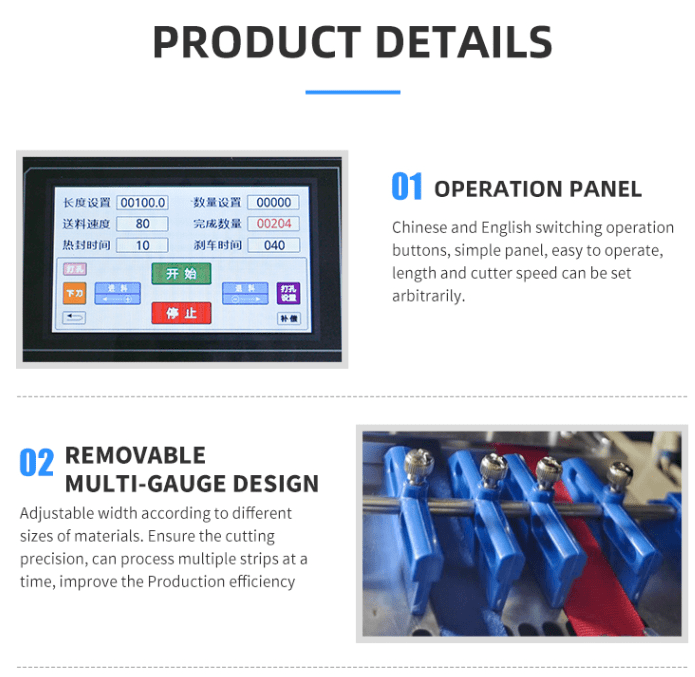

| Touchscreen PLC | Program length, quantity, and speed easily |

| Batch Counter & Alarm | Helps monitor production progress |

| Multi-Material Support | Works with polyester, PP, elastic, and more |

One of our buyers in Canada used to cut nylon loops for medical support belts manually. After switching to our automatic nylon strap cutting machine, his team tripled their output and completely eliminated customer complaints about loose fibers.

How Does the Machine Work?

The automatic nylon cutting machine operates by integrating precise motor control and thermal blade technology.

Process Breakdown:

Material Loading

Nylon webbing or tape is loaded onto rollers or a coil spindle.Feeding System

A servo-driven roller pulls the material with consistent tension.Length Setting

The system uses encoders to measure length down to the millimeter.Hot or Cold Cutting

A hot knife blade cuts and seals nylon in one step. Cold blades are used for coated or laminated nylon.Batch Completion

The machine automatically stops or continues based on your preset quantity.

You can easily switch between materials by adjusting the blade temperature, feed speed, or blade pressure.

Why Nylon Requires a Special Machine

Nylon melts before it burns. That’s both a challenge and an opportunity.

Using a hot knife cutter allows the blade to melt the fibers along the cut edge—creating a sealed finish that won’t unravel.

Manual scissors or standard blades leave frayed, weak edges. That leads to:

- Poor visual quality

- Product failure in field use

- Rework and material loss

That’s why HAOXINHE nylon cutting machines are built with adjustable temperature controls and optional Teflon-coated blades.

Material Compatibility

Besides nylon, our automatic cutter also works with:

| Material | Application |

|---|---|

| Polyester | Safety harnesses, straps |

| Polypropylene (PP) | Lightweight woven tape |

| Elastic | Waistbands, loop straps |

| PVC-coated nylon | Outdoor covers, tarpaulins |

| Kevlar (custom blade) | Fire-resistant straps |

We always test samples before finalizing the configuration for new clients. This ensures 100% compatibility with your material thickness, weave, and stretch resistance.

Why Choose Suzhou Haoxinhe?

We are a factory with five production lines focused on cutting automation. We don’t resell — we design and manufacture.

Advantages of our nylon cutting machines:

- Custom machine size — match your material width

- Optional punching and labeling — save time downstream

- Remote setup support — smooth installation, fast operation

- Durable components — for long-term industrial use

We’ve served clients in Germany, Singapore, Italy, North America, and beyond. All of them have unique materials and applications—but we always customize to fit.

Who Needs This Machine?

This machine is ideal for:

- Apparel factories (collar tape, brand loops)

- Outdoor gear manufacturers (tent straps, backpack belts)

- Automotive suppliers (seatbelt accessories)

- Industrial packaging teams (straps, bindings)

- Sportswear brands (elastic and woven nylon)

Even small factories can benefit from this upgrade. With fewer workers and better speed, your ROI comes fast.

Conclusion

An automatic nylon cutting machine delivers sealed edges, accurate lengths, and fast cycles—perfect for high-volume synthetic material processing.

Insights:

An automatic nylon cutting machine is a precision device that feeds and cuts nylon materials such as webbing, tape, and straps. Using servo motors and a hot knife blade, it cuts cleanly and seals the edges in a single motion. This eliminates fraying and speeds up production. Suzhou Haoxinhe Electrical Equipment Co., Ltd. offers customizable nylon cutting machines ideal for apparel, automotive, outdoor gear, and packaging industries. With features like batch control, digital settings, and high-speed operation, it’s the smartest upgrade for any synthetic textile factory.