What is an Automated Belt Cutting Machine and Which is the Best Digital Cutting Machine?

Cutting belts and materials manually slows down production, wastes resources, and leads to inconsistent quality. Is your factory still stuck in that cycle?

An automated belt cutting machine1 cuts thick webbing materials precisely and efficiently. The best digital cutting machine2es](https://www.americanmicroinc.com/resources/digital-cutting-vs-die-cutting/)[^3] offer advanced control, flexibility, and high-speed performance.

Still unsure which machine fits your factory needs? Let me explain both clearly so you can choose wisely.

What is an Automated Belt Cutting Machine?

Manual belt cutting leads to uneven lengths and frayed edges. This frustrates workers and reduces product quality.

An automated belt cutting machine1 is a programmable device that cuts belts made of nylon, polyester, or other webbing materials with precision and speed.

How It Works

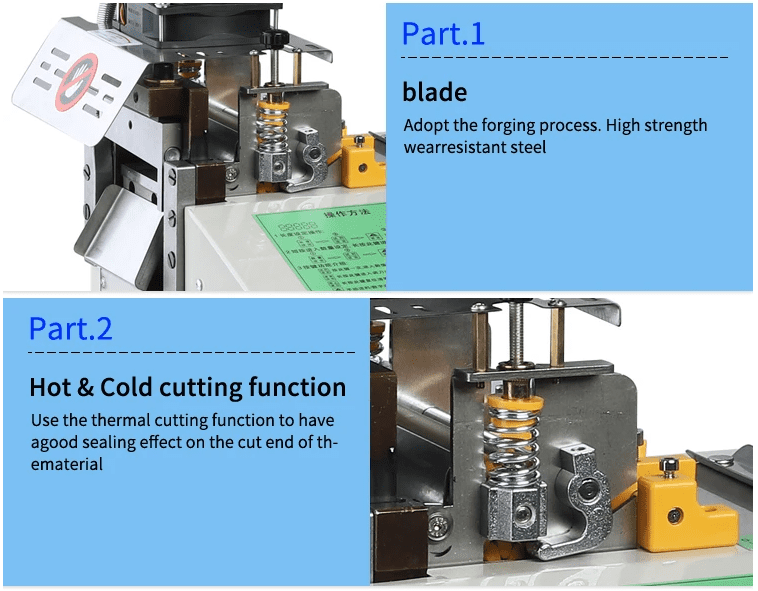

This machine automatically feeds the webbing, measures exact lengths, and uses blades—either hot or cold—to cut the material cleanly. It reduces labor and minimizes cutting errors.

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., our webbing ribbon cutting machine is designed for:

- Seatbelts

- Harness straps

- Luggage belts

- Industrial tie-downs

- Safety webbing

Key Features of Our Belt Cutting Machines

| Feature | Benefit |

|---|---|

| Hot & Cold Blade Options | Choose based on material type |

| Precision Length Control | Prevents material waste |

| Programmable Cutting | Ideal for bulk orders |

| Batch Counting | Streamlines production planning |

| Optional Punching & Labeling | Custom add-ons available |

One of our clients in Germany needed a rotary bevel cutting machine for angled cuts on thick polyester belts. We developed a custom module for him. Now, his production line runs 30% faster with perfect angle cuts every time.

Why It’s a Must-Have

If you’re in manufacturing or logistics, speed and precision matter. An automated belt cutting machine1 gives you:

- Consistent quality

- Less waste

- Fewer human errors

- Better productivity

What is the Best Digital Cutting Machine?

Generic machines often struggle with modern materials. They can’t handle detailed patterns, soft curves, or multi-layer cuts. That’s a bottleneck in product development.

The best digital cutting machine2 is one that offers flexibility, fast switching between jobs, and clean cuts across different materials with minimal manual adjustment.

What Defines a "Best" Digital Cutter?

Digital cutting machines are used in industries like printing, packaging, fashion, and signage. They use software and servo motors to guide a blade, laser, or router along complex paths.

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., our digital cutting systems come with:

- High-resolution touch control panels

- Auto-sensing material thickness

- Support for AI/PLT/DXF file formats

- Optional CCD camera for printed mark alignment

Here’s a real scenario: A Canadian client wanted to cut both foam sheets and PVC edge bands with the same machine. We recommended our Protective Foam Cutting Machine with a multi-blade digital module. It saved him the cost of buying two separate machines and improved his product output consistency.

Comparing Digital Cutter Options

| Model | Ideal For | Cutting Method | Special Features |

|---|---|---|---|

| HX-100 | Labels, films | Cold knife | Auto-alignment |

| HX-200 | Foam, PVC | Hot + digital knife | Multi-layer cut |

| HX-150 | Webbing shapes | Round blade | Touch panel + presets |

Why Choose Digital?

Digital cutting machines are ideal when:

- You change materials often

- You cut complex or curved shapes

- You need high accuracy

- You want to reduce setup time

If you’re producing small-batch custom products, digital cutters are your best bet. They’re faster to set up than traditional die-cutting systems and require fewer operators.

Conclusion

Automated belt cutting machines are perfect for consistent, heavy-duty webbing jobs. Digital cutting machines are your go-to for flexibility and fine detail. Choose the right machine for your production goals.

Insights:

An automated belt cutting machine1 is a programmable tool that cuts thick belts or webbing materials like nylon, polyester, and seatbelt straps with speed and accuracy. It reduces manual errors, improves production efficiency, and ensures clean edges—especially when using hot knife technology. The best digital cutting machine2 offers advanced controls, supports multiple file formats, and handles a wide range of materials such as foam, films, and PVC. For industries that require frequent material changes or precise pattern cutting, digital machines like those made by Suzhou Haoxinhe Electrical Equipment Co., Ltd. provide unmatched flexibility and performance.