Automatic Air Bubble Poly Film Cutting Machine: Everything You Need to Know

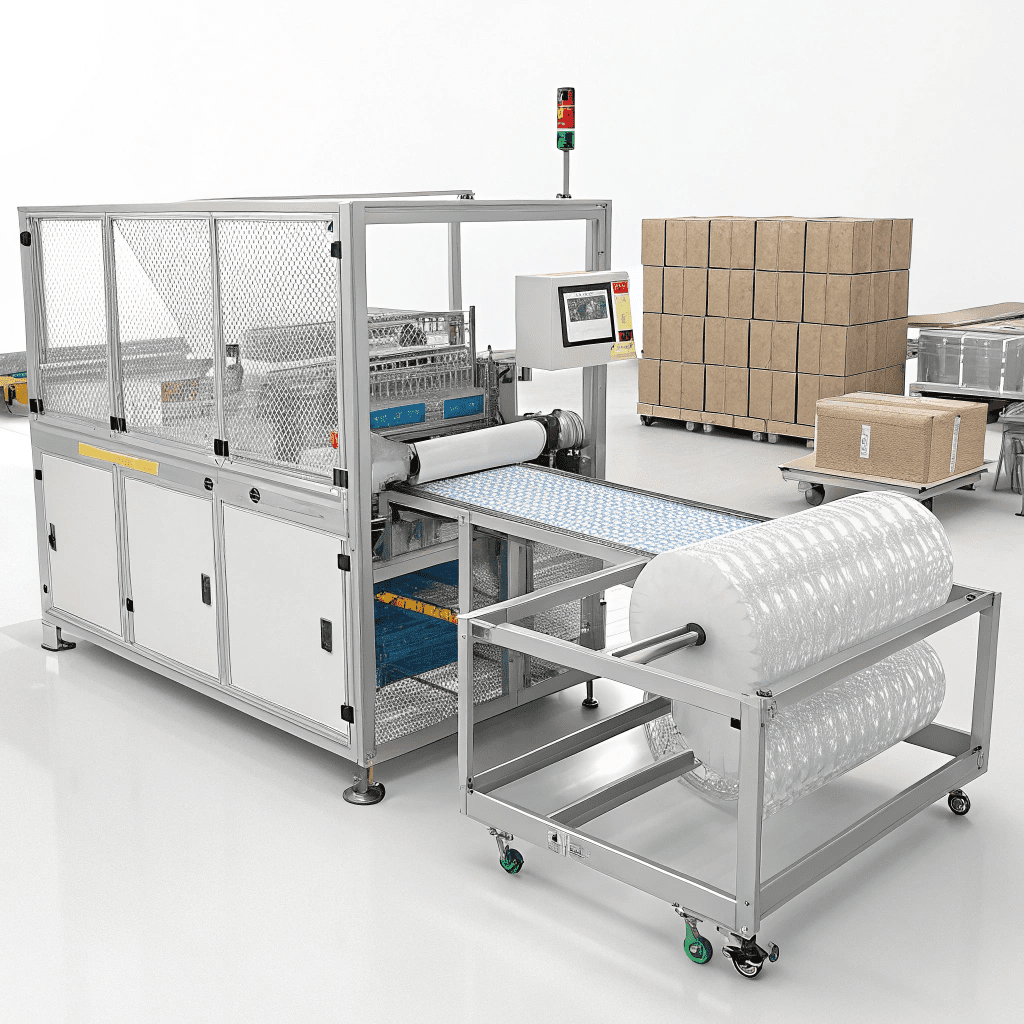

Have you ever wondered how air bubble poly film is precisely cut for packaging purposes? The answer lies in the advanced technology of automatic air bubble poly film cutting machine1s. These machines are essential in industries like manufacturing, logistics, and e-commerce for efficient packaging solutions.

An automatic air bubble poly film cutting machine1 is a specialized device designed to cut air bubble wrap with precision and speed. It ensures clean edges and reduces material waste, making it ideal for large-scale production environments.

Let’s dive deeper into the features, applications, and benefits of these machines, as well as their role in modern packaging processes.

What is a Bubble Wrap Cutter?

Bubble wrap cutters are a type of automatic cutting machine specifically designed for handling air bubble poly film. They streamline the process of cutting bubble wrap into custom sizes for various packaging needs.

A bubble wrap cutter is a machine that precisely cuts air bubble film into sheets or rolls of desired dimensions. It is widely used in industries like shipping, e-commerce, and retail to ensure efficient and fast packaging.

Key Features of a Bubble Wrap Cutter

Here are some of the standout features of bubble wrap cutters:

- Precision Cutting: Ensures clean, accurate cuts with minimal material waste.

- Adjustable Settings: Allows customization of cut lengths and widths.

- Automated Operation: Reduces manual labor and increases efficiency.

- Versatility: Compatible with various thicknesses and types of bubble wrap.

Applications of Bubble Wrap Cutters

Bubble wrap cutters are used in multiple industries:

- E-commerce: For packaging fragile items during shipping.

- Logistics: To protect goods during transportation.

- Manufacturing: For wrapping products before storage or delivery.

- Retail: For in-store packaging solutions.

Benefits of Using a Bubble Wrap Cutter

Using a bubble wrap cutter2 offers several advantages:

- Time-Saving: Automates the cutting process, reducing manual effort.

- Cost-Effective: Minimizes material waste, lowering overall costs.

- Consistency: Ensures uniform cuts for professional packaging.

- Ease of Use: Simple operation with minimal training required.

Types of Bubble Wrap Cutters

Here’s a comparison of common types:

| Type | Features | Best For |

|---|---|---|

| Manual Cutter | Hand-operated, portable | Small-scale operations |

| Semi-Automatic | Partially automated, adjustable | Medium-scale production |

| Fully Automatic | Fully automated, high-speed | Large-scale manufacturing |

How Does an Automatic Air Bubble Poly Film Cutting Machine Work?

Understanding the working mechanism of these machines can help you appreciate their efficiency and reliability.

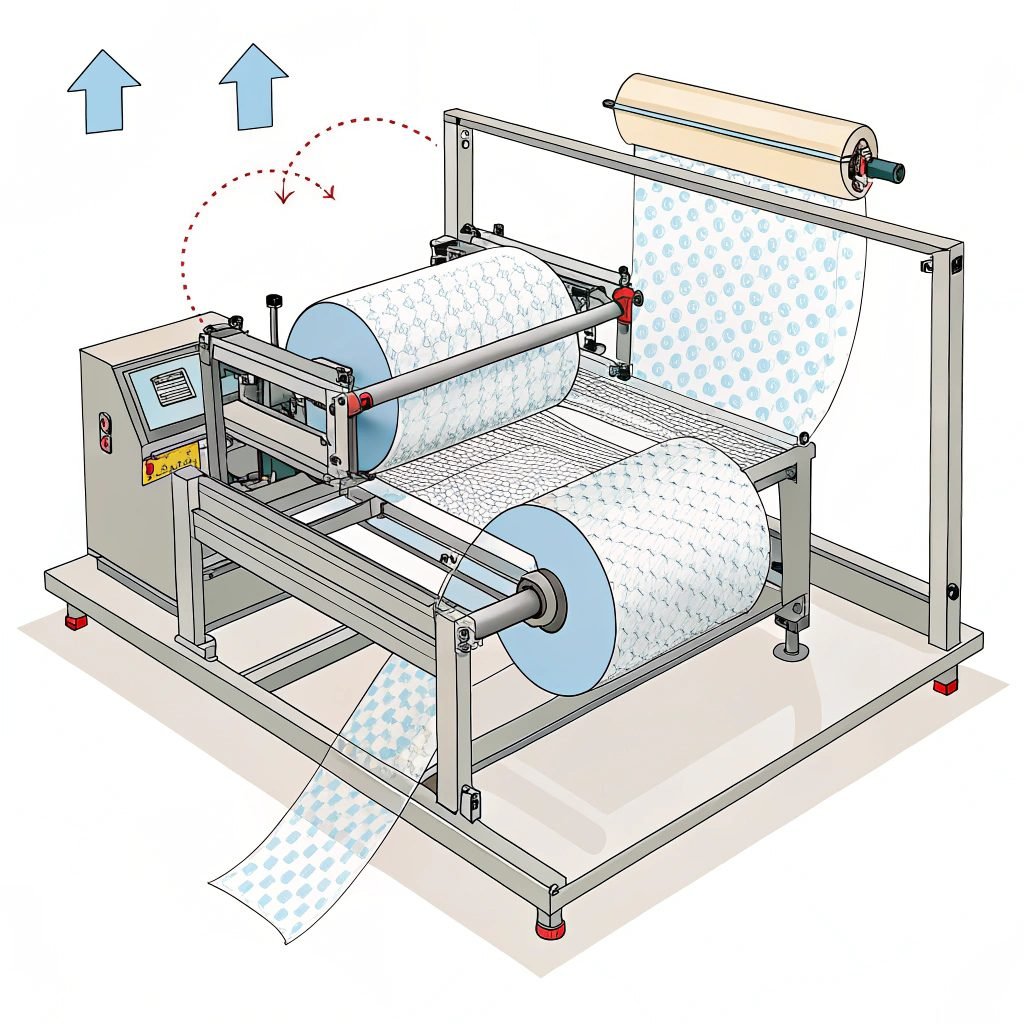

An automatic air bubble poly film cutting machine1 operates by feeding the film through a series of rollers and blades. The machine measures and cuts the film according to preset dimensions, ensuring accuracy and consistency.

Step-by-Step Process

Here’s how the machine works:

- Feeding: The roll of air bubble film is loaded into the machine.

- Measurement: Sensors detect the required length and width.

- Cutting: Blades or lasers cut the film accurately.

- Output: The cut sheets or rolls are collected for packaging.

Advanced Features to Look For

When choosing a machine, consider these advanced features:

- Digital Control Panel: For easy programming and adjustments.

- Safety Mechanisms: Such as emergency stop and blade guards.

- Energy Efficiency: To reduce operational costs.

Maintenance Tips

To ensure longevity and optimal performance:

- Regularly clean the blades and rollers.

- Lubricate moving parts as recommended.

- Check for wear and tear, especially on cutting components.

Why Choose an Automatic Air Bubble Poly Film Cutting Machine?

Investing in an automatic cutting machine can revolutionize your packaging process. Here’s why it’s worth considering.

An automatic air bubble poly film cutting machine1 offers unmatched efficiency, precision, and cost savings. It’s a game-changer for businesses looking to optimize their packaging operations.

Advantages Over Manual Cutting

Compared to manual methods, automatic machines offer:

- Higher Speed: Cuts more material in less time.

- Better Accuracy: Ensures consistent dimensions.

- Reduced Labor Costs: Minimizes the need for manual intervention.

Industry Applications

These machines are widely used in:

- E-commerce Platforms: For rapid packaging of online orders.

- Logistics Companies: To protect goods during transit.

- Manufacturing Units: For wrapping products before shipment.

Cost-Benefit Analysis

While the initial investment may seem high, the long-term benefits include:

- Lower Material Costs: Reduced waste and efficient usage.

- Increased Productivity: Faster cutting and packaging.

- Improved Packaging Quality: Professional and consistent results.

Conclusion

Automatic air bubble poly film cutting machines and bubble wrap cutters are indispensable tools in modern packaging operations. They offer precision, efficiency, and cost savings, making them ideal for businesses of all sizes. By understanding their features and benefits, you can make an informed decision to enhance your packaging process.