Noise reduction techniques for industrial dog collar punching?

Loud machine noise is more than annoying—it’s a health risk and a productivity killer in your factory.

To reduce noise in dog collar punching, upgrade to servo-driven systems1, use sound-dampening materials, and regularly maintain your machine parts.

1: Modify the punching process by optimizing machine parameters to reduce impact noise.

2: Install noise reduction equipment2 like acoustic covers3 and vibration dampers.

3: Use specialized low-noise punching tools4 to minimize mechanical sound.

4: Enclose the punching area with soundproofing barriers5 or absorbent panels.

5: Combine operational changes with physical noise-control solutions for maximum effectiveness in industrial dog collar manufacturing.

This strategy significantly reduces noise pollution while improving workplace safety and compliance.

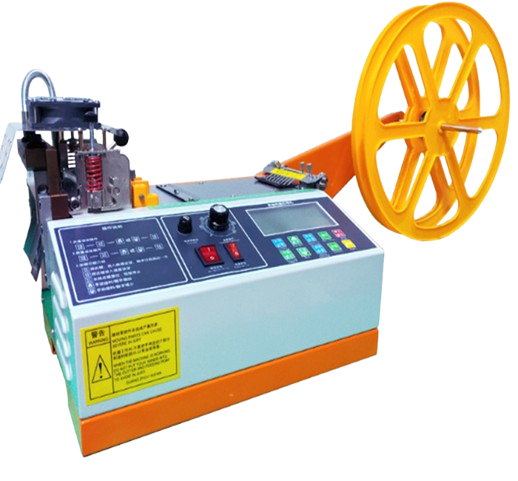

A few years ago, when we were running early versions of our automatic punching cutting machines at Suzhou Haoxinhe Electrical Equipment Co., Ltd., we noticed that operators were rotating shifts more often due to noise fatigue. Once we switched from clutch motors to servo systems and added protective acoustic panels, we saw an immediate drop in workplace complaints—and productivity went up.

Decibel level comparison: servo motors vs traditional clutch systems?

Clutch motors are loud, inefficient, and outdated—they make conversation near impossible during full-speed punching operations.

Servo motors are significantly quieter than clutch systems, often reducing decibel levels by 20–30 dB in industrial punching setups.

Measuring noise differences

We tested two setups during a trial production run for our dog collar punching clients:

| System Type | Average dB During Operation | Notes |

|---|---|---|

| Traditional Clutch Motor | 85–95 dB | Sharp spikes, irregular vibration, metal grinding |

| Servo Motor System | 60–70 dB | Smooth ramp-up, consistent tone, minimal shock |

According to occupational health standards, any exposure above 85 dB requires hearing protection. So it’s easy to see why more of our customers—especially those who operate around-the-clock facilities—are switching to quieter options.

What makes servo systems quieter?

- No constant running motor: Servo only activates when needed.

- Less vibration: Digital control ensures smoother motion.

- Better mechanical balance: Reduces machine resonance.

- No clutch engagement noise: Eliminates the loud snapping sound of traditional motors.

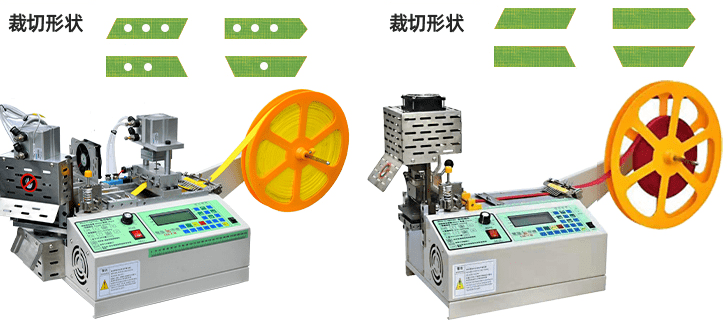

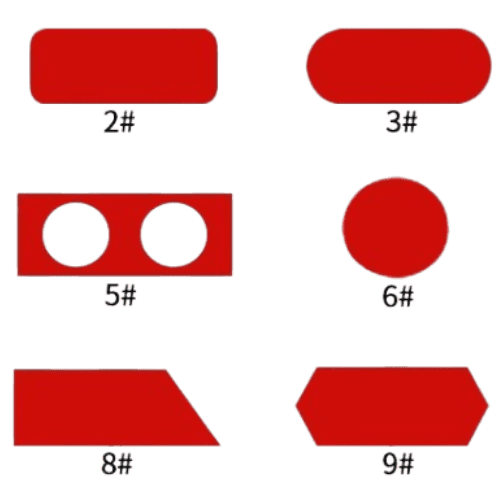

For example, our rotary bevel cutting machine and high-speed trademark cutting machine use servo drives that not only lower noise but also increase accuracy. This is especially useful for punching materials like webbing tape and PVC edge banding used in collar manufacturing, where precision and comfort matter just as much as efficiency.

Tips for further noise control

- Add sound insulation panels6 to machine enclosures.

- Place anti-vibration pads7 under machine legs.

- Use lubrication on all moving parts to reduce friction sounds.

- Perform routine maintenance8 to catch worn bearings or belts early.

At Suzhou Haoxinhe, we’ve integrated many of these solutions into our Protective Foam Cutting Machine and Bubble Wrap Cutting Machine models, making them suitable for environments where noise limits are strictly enforced.

Conclusion

Switching to servo motors is the easiest and most effective way to cut noise from industrial dog collar punching operations.

Insights

Noise control is a competitive edge. Suzhou Haoxinhe Electrical Equipment Co., Ltd. specializes in quiet, efficient cutting and punching systems like servo-based webbing ribbon cutting machines and automatic punching cutting machines. These help our clients meet workplace safety standards while keeping operators productive and focused.

Learn how servo-driven systems can significantly lower noise levels and improve operational efficiency in your facility. ↩

Explore this link to discover effective noise reduction solutions that can enhance workplace safety and productivity. ↩

Explore how acoustic covers can effectively dampen noise and improve the working environment in industrial settings. ↩

Discover specialized low-noise punching tools that can help reduce mechanical sound in your manufacturing process. ↩

Find out about soundproofing barriers that can effectively minimize noise pollution in your industrial workspace. ↩

Discover the advantages of sound insulation panels in creating a quieter and more productive factory environment. ↩

Learn how anti-vibration pads can enhance machine stability and reduce noise levels in your operations. ↩

Understand the significance of routine maintenance in preventing noise issues and ensuring machinery operates smoothly. ↩