What is a Paper Cutting Machine and What Are the Different Types?

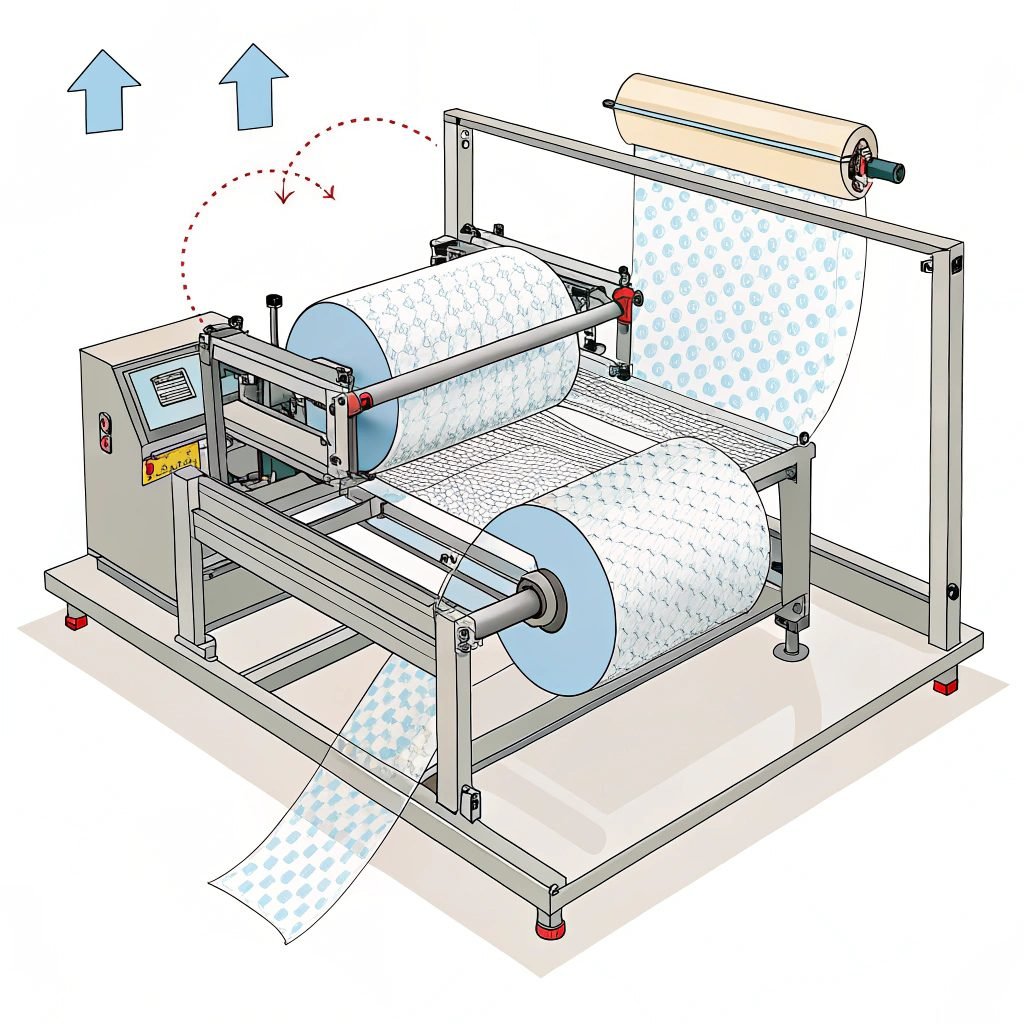

[^1]s for bulk materials](https://hxcuttingmachine.com/wp-content/uploads/2025/03/3-md-image-generation-for-different-types-of-bub.jpg)

Still using manual cutters for paper materials? That slows you down and reduces consistency—especially for bulk orders.

A paper cutting machine1 is a mechanical or automated device that cuts sheets, rolls, or stacks of paper into specific sizes or shapes with precision and speed.

Let’s explore how it works, and which type is right for your production needs.

What is a Paper Cutting Machine?

Manual cutting methods are not accurate enough for industrial production. Crooked cuts, uneven stacks, and wasted material are common problems.

A paper cutting machine1 is used in printing, packaging, labeling, and converting industries to cut paper, film, or similar materials into uniform sizes.

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we design industrial paper cutting machine1s used for:

- Roll-to-sheet paper conversion

- Label and sticker cutting

- Film or laminated paper trimming

- Protective foam sheet cutting

- Heat-sensitive packaging sheet cutting

Our machines are widely used by buyers in Europe, Southeast Asia, and North America who require fast, clean, and repeatable cutting processes.

What Are the Different Types of Paper Cutting Machines?

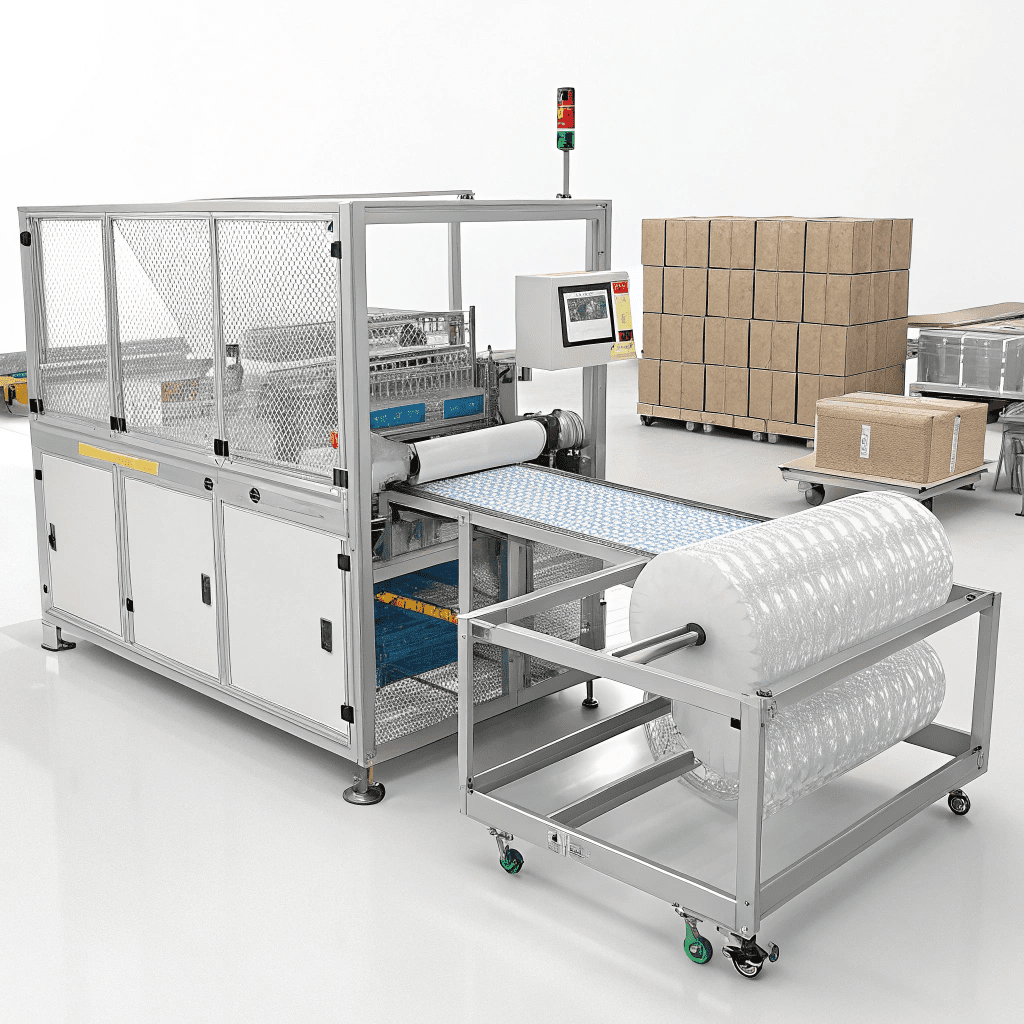

[^1]s](https://hxcuttingmachine.com/wp-content/uploads/2025/03/4.png)

The right type of machine depends on the format of your paper, the thickness, and your required volume. Let’s break down the most common options.

1. Manual Paper Cutter

- Used for: Offices, schools, small shops

- Operation: Hand-operated blade or guillotine arm

- Pros: Low cost, easy to use

- Cons: Low volume, not suitable for thick stacks

These are also called trimmers or stack cutters and are not ideal for industrial use.

2. Semi-Automatic Paper Cutting Machine

- Used for: Small to medium-scale factories

- Operation: Manual feeding + powered blade or hydraulic press

- Pros: Faster than manual, suitable for medium jobs

- Cons: Labor required, not ideal for continuous cutting

A common setup includes a foot pedal to activate the blade, with a clamp to hold paper in place.

3. Fully Automatic Paper Cutting Machine

- Used for: Large-volume manufacturing

- Operation: Automatic feeding, clamping, cutting, and stacking

- Pros: High speed, accurate, continuous operation

- Cons: Higher investment cost, larger space needed

At HAOXINHE, our automatic webbing tape cutting machine and bubble wrap cutting machine fall into this category. They’re built for fast-paced B2B environments.

4. Roll-to-Sheet Paper Cutting Machine

- Used for: Converting paper rolls into flat sheets

- Operation: Paper is unwound, measured, and cut into sheets

- Pros: Ideal for packaging, printing, and film applications

- Cons: Requires precise tension and speed control

This is one of our most requested machines. It handles kraft paper, laminated paper, foam sheets, and more.

5. Digital/Computer-Controlled Cutting Machine

- Used for: Custom cuts, prototyping, labels

- Operation: Controlled by software (DXF, PLT files), uses blade or laser

- Pros: Great for complex shapes and printed mark alignment

- Cons: Slower for mass cutting unless upgraded

These are ideal for high-precision, short-run jobs, like logo tags, sticker sheets, or decorative packaging elements.

6. Hot Knife Paper Cutting Machine

- Used for: Heat-sensitive synthetic papers or laminated films

- Operation: Cuts and seals edge with a heated blade

- Pros: Prevents fraying or edge curling

- Cons: Not suitable for natural or thick papers

This is used mostly in textile labeling or multi-layer paper applications.

Paper Cutting Machine Selection Guide

| Type | Best For | Operation Style | Speed | Volume |

|---|---|---|---|---|

| Manual | Small office use | Manual | Low | Very low |

| Semi-Automatic | Entry-level factories | Hybrid | Medium | Low–Medium |

| Fully Automatic | Large-scale production | Fully Automated | High | High |

| Roll-to-Sheet | Printing/Packaging | Servo + rotary | High | Very High |

| Digital Cutter | Custom labels | Software-controlled | Medium | Low–Medium |

| Hot Knife Cutter | Laminated/film paper | Heated blade | High | Medium–High |

Why Choose Haoxinhe Paper Cutting Machines?

Suzhou Haoxinhe Electrical Equipment Co., Ltd. is a trusted name in industrial cutting systems.

We don’t just sell machines—we provide custom solutions based on your material, application, and speed requirements.

Our Popular Models for Paper Cutting Include:

- Automatic hot and cold cutting machines

- Protective foam sheet cutting machines

- PVC edge banding paper cutters

- Computer tube and label cutting machines

- Roll-fed round shape cutting machines

We provide:

- Free material testing

- Remote video demonstrations

- Multi-language interface support

- Logistics and customs help

- Long-term parts support

We’ve served clients in Germany, France, Singapore, Canada, and more—helping them scale from small factories to export-grade production lines.

Who Should Use an Industrial Paper Cutter?

This machine is ideal for:

- Printing & publishing factories

- Packaging material converters

- Thermal paper roll processors

- Label and sticker manufacturers

- Gift wrap and decorative sheet production

Whether you’re cutting kraft paper, laminated film, or synthetic labels, we can match you with the best machine.

Conclusion

A paper cutting machine1 is essential for any production line that deals with paper, film, or sheet materials. The right type depends on your speed, material, and budget.

Insights:

A paper cutting machine1 is designed to cut sheets, rolls, or stacks of paper with precision. There are several types, including manual cutters, semi-automatic guillotine cutters, roll-to-sheet machines, and digital or hot knife systems. For factories, a fully automatic paper cutting machine2e](https://en.wikipedia.org/wiki/Paper_cutter)[^1] saves time, reduces waste, and improves product quality. Suzhou Haoxinhe Electrical Equipment Co., Ltd. offers customizable, industrial-grade paper cutting machine1s built for packaging, printing, labeling, and textile applications.