Which machine to cut gasket is the best?

Cutting gaskets precisely is essential for sealing applications. Choosing the right machine can save time, reduce waste, and improve efficiency. But with so many options available, how do you pick the best one?

The best machine for cutting gaskets depends on the material, thickness, and required precision. Popular choices include die-cutting machines, CNC cutters1, laser cutters, and waterjet machines. Each offers unique advantages for different applications.

Selecting the right gasket-cutting machine requires understanding its working mechanism and suitability for your needs. Let’s explore the best ways to cut gaskets and the top machines available.

What is the best way to cut gasket?

The best method for cutting a gasket depends on precision, material type, and production volume. Manual cutting works for simple jobs, while automated methods like laser or waterjet cutting2 ensure high accuracy.

The best way to cut a gasket is by using a die-cutting, CNC, laser, or waterjet machine. These methods provide precision, speed, and efficiency, making them ideal for industrial applications.

Manual Cutting: Suitable for Small Jobs

Manual cutting with a utility knife or scissors is a low-cost option for soft materials. However, it lacks precision and is not ideal for complex shapes.

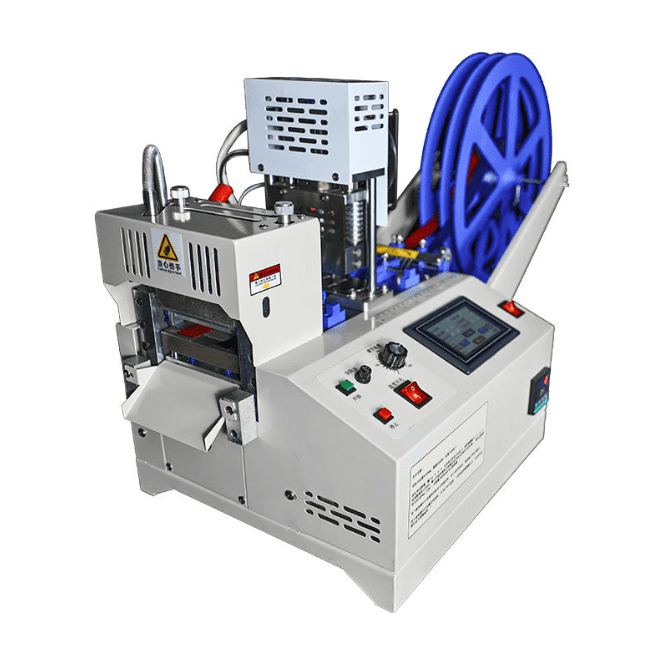

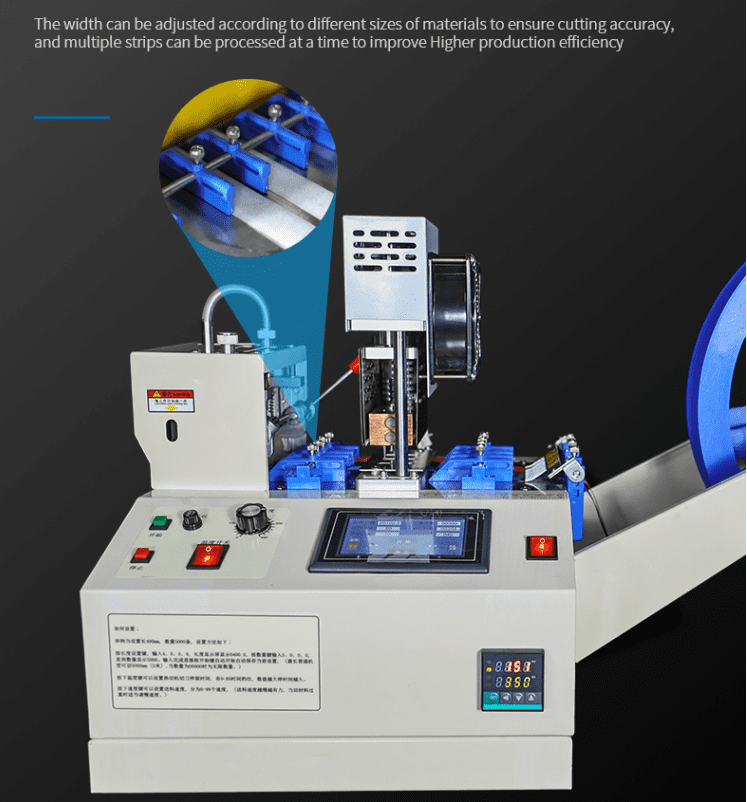

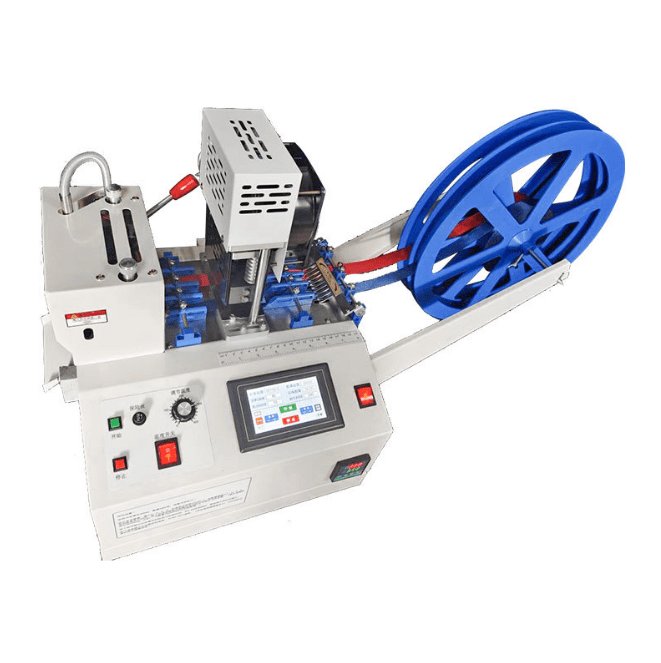

Die Cutting: Best for High-Volume Production

Die-cutting machines use steel-rule dies to cut gaskets in bulk. They are efficient for mass production but require custom dies.

CNC Cutting: Versatile and Precise

CNC machines use digital designs to cut gaskets from various materials. They offer high precision and repeatability, making them ideal for complex shapes.

Laser Cutting: High Precision for Thin Materials

Laser cutters provide clean, precise cuts without physical contact. They are perfect for thin and non-metallic gaskets but may struggle with thicker materials.

Waterjet Cutting: Best for Thick and Tough Materials

Waterjet cutting machines use high-pressure water to cut through thick gaskets. They are ideal for materials like rubber, metal, and composites.

Each method has advantages and limitations. Choosing the best approach depends on your specific needs, including material type, production volume, and required precision.

Conclusion

Choosing the best gasket-cutting machine depends on material type, precision, and production volume. CNC, laser, and waterjet cutters offer high efficiency, while die-cutting suits mass production.

Insights

- For high-volume production, die-cutting machines are the most efficient.

- For precision and flexibility, CNC or laser cutting3 is ideal.

- For cutting thick materials, waterjet cutting is the best option.

- Manual cutting works for small, simple jobs but lacks accuracy.

Explore the benefits of CNC cutters for gasket cutting, including precision and versatility, to make an informed choice. ↩

Learn about the advantages of waterjet cutting for thick materials, ensuring you choose the right method for your gasket needs. ↩

Discover how laser cutting enhances efficiency and precision in gasket manufacturing, making it a top choice for many applications. ↩