10 Most Reliable Bubble Wrap Cutting Machines (User Feedback + Maintenance Tips)

Frustrated by downtime, repairs, and unreliable cutting results?

In this 2026 guide, we rank the 10 most reliable bubble wrap cutting machines1 based on real user feedback2—and we include essential maintenance tips to keep them running smoothly.

Whether you’re buying for a high-speed production line or a small packaging station, this list will help you invest with confidence.

Why reliability matters when choosing a bubble wrap cutting machine?

One breakdown can delay hundreds of packages or shipments.

A reliable bubble wrap cutting machine delivers consistent output with minimal repairs—saving you both time and money in the long run.

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we build machines that prioritize durability, cutting precision3, and export-compliant quality. Buyers like Mark Chen rely on models like our HX-F350 Bubble Wrap Cutting Machine to run daily without interruptions or constant technician calls.

🔧 What Makes a Machine Reliable?

| Factor | Why It Matters |

|---|---|

| Motor + Blade Durability | Withstands long production shifts |

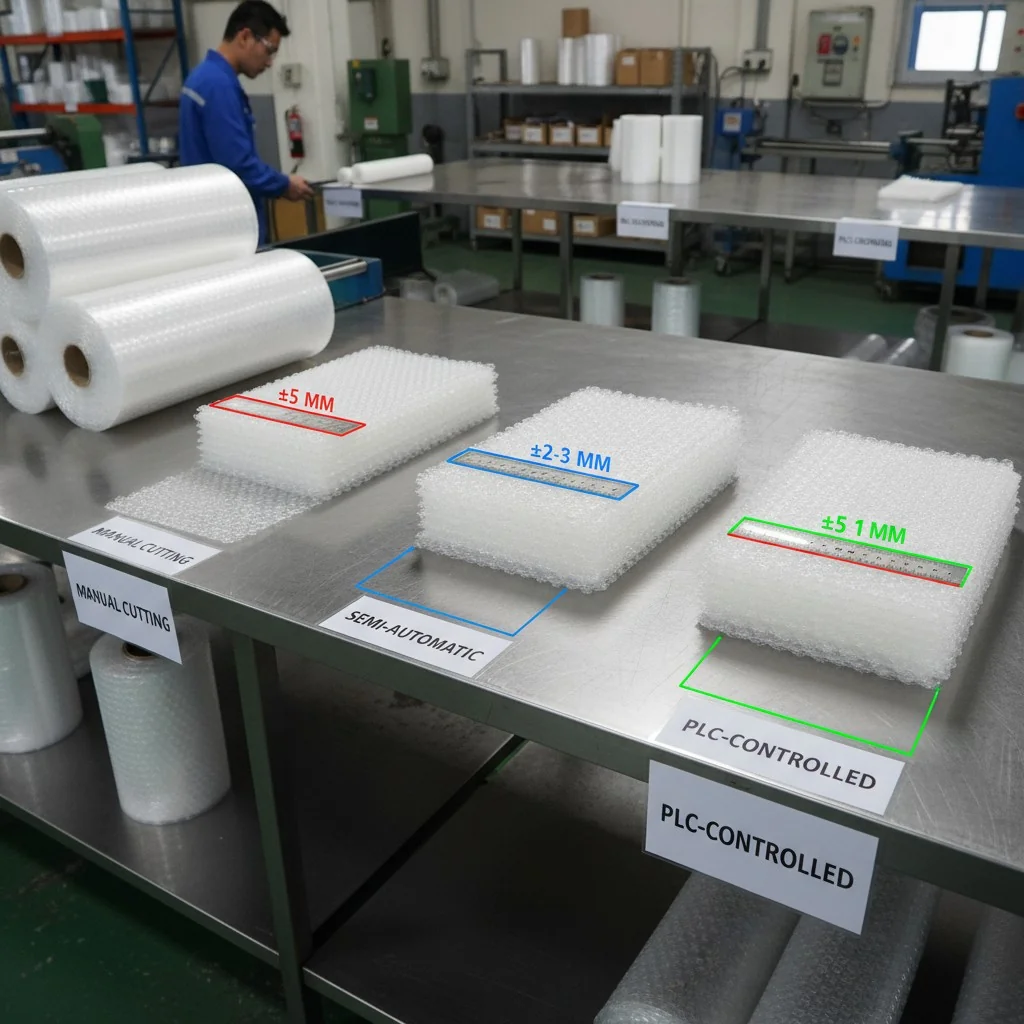

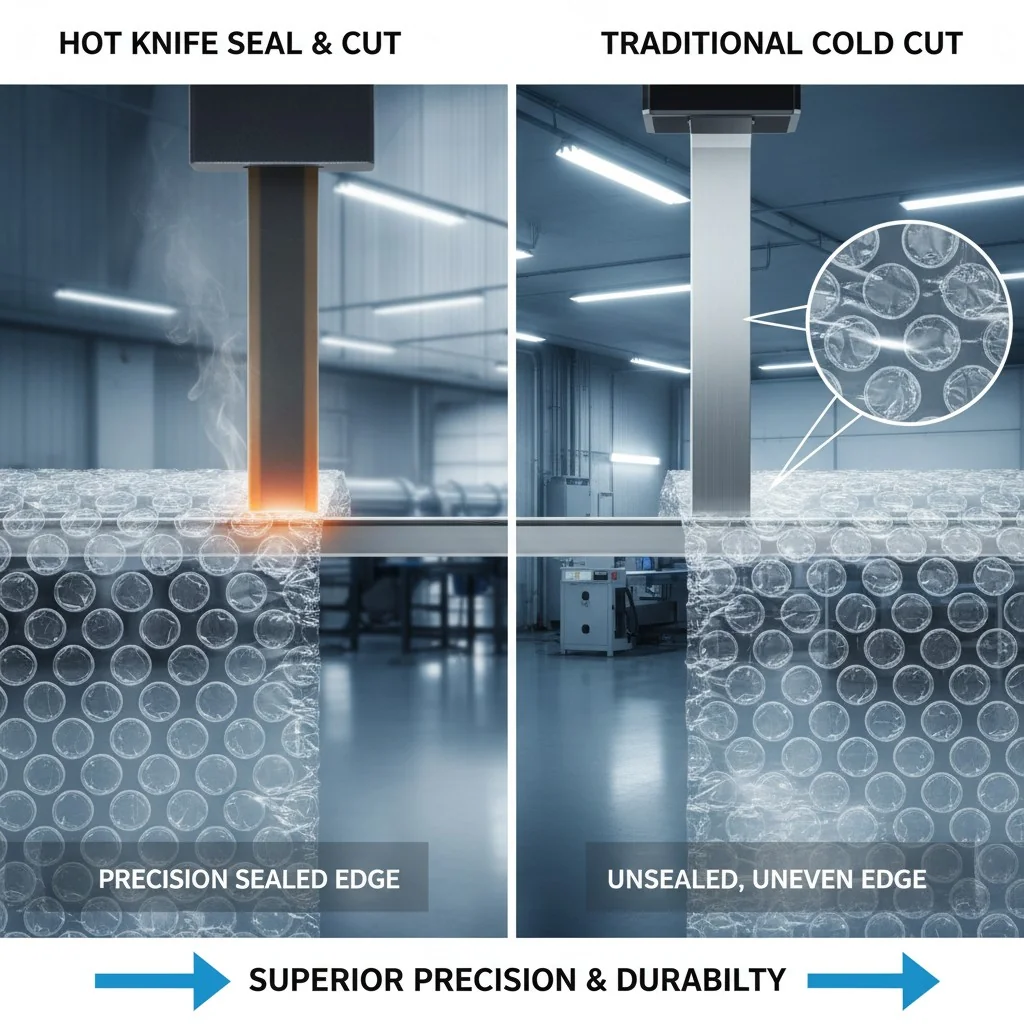

| Cutting Accuracy | Maintains quality after months of use |

| Ease of Maintenance | Quick to clean, inspect, or replace parts |

| Support Availability | Fast service reduces downtime |

| Certification | Ensures safety and build quality |

1. HAOXINHE HX-500 – Most Reliable All-Around Cutter

Users report 95%+ uptime with this model.

The HX-500 combines durability, cutting consistency, and easy-to-access components for fast maintenance.

| Price | $4,500 |

| Speed | 35 m/min |

| Best For | Mid-size factories, exporters |

| User Rating | ★★★★★ |

🛠️ Maintenance Tip:

- Wipe down the blade guide and check feed rollers every 2 weeks.

- Replace blade every 3–6 months depending on usage volume.

2. Trimax TRX-1000 – Top Reliability in High-Speed Environments

Built for 24/7 operation with minimal failure reports.

TRX-1000 includes a self-cooling motor and reinforced cutter track.

| Price | $8,200 |

| Speed | 45 m/min |

| Reliability Score | ★★★★★ |

🛠️ Maintenance Tip:

- Lubricate moving parts monthly.

- Keep motor housing clear of dust buildup.

3. KEQI KQ-FCUT – Best for Consistent Multi-Material Performance

Users switching between foam, EVA, and bubble wrap say this machine handles it all without frequent recalibration.

| Price | $7,600 |

| Speed | 42 m/min |

| Reliability Score | ★★★★☆ |

🛠️ Maintenance Tip:

- Clean blade path when changing material types.

- Run auto-calibration weekly.

4. Ztech ZT-BWC500 – Smart Features, Strong Build

Equipped with touchscreen alerts and fault diagnosis to reduce human error.

| Price | $6,800 |

| Speed | 40 m/min |

| User Feedback | “Low-maintenance, reliable every shift.” |

🛠️ Maintenance Tip:

- Check sensor lenses monthly.

- Back up cutting presets every quarter.

5. Renzor RZ-CutPro – Most Reliable for Accurate Repetitive Cuts

Popular in printing and packaging departments for its precision and long blade life.

| Price | $5,900 |

| Speed | 38 m/min |

| Material Support | Wrap, kraft paper |

🛠️ Maintenance Tip:

- Inspect the blade alignment every 10 days.

- Use compressed air to clean optical guide.

6. WinPack WP-AutoWrap – Dual Use, Built to Last

Runs both edge banding and bubble wrap cutting functions reliably with dual-mode programming4.

| Price | $7,900 |

| Speed | 41 m/min |

| Best For | Furniture and appliance factories |

🛠️ Maintenance Tip:

- Alternate cutting modes weekly to prevent motor strain.

- Replace feed belt annually.

7. SuperCut SC-300 – Safety & Reliability for Chemical Use

Strong build, even for sensitive environments like chemical packaging.

| Price | $6,000 |

| Speed | 36 m/min |

| Features | Blade shield, auto stop-sensor |

🛠️ Maintenance Tip:

- Clean shield lenses regularly.

- Run full safety system test monthly.

8. YUSH YS-PWM550 – Precision & Speed with Low Downtime

Medical device shippers use this for both speed and reliability under strict standards.

| Price | $9,000 |

| Speed | 50 m/min |

| User Feedback | “Zero issues after 6 months of daily use.” |

🛠️ Maintenance Tip:

- Use anti-static wipes on blade housing weekly.

- Run diagnostic system check5 quarterly.

9. JOTA JT-CW350 – Most Reliable Entry-Level Machine

Simple, reliable, and easy for teams with little technical knowledge.

| Price | $5,300 |

| Speed | 32 m/min |

| Automation | Basic auto-feed/cut |

🛠️ Maintenance Tip:

- Check drive belts monthly.

- Replace blade every 4 months for optimal performance.

10. PACKEX PX-B350 – Minimalist Design, Maximum Uptime

Ideal for repetitive bubble wrap cutting in basic operations.

| Price | $5,200 |

| Speed | 34 m/min |

| Features | Simple controls, easy blade access |

🛠️ Maintenance Tip:

- Tighten all fasteners quarterly.

- Dust machine after each shift to extend part life.

User Reliability Ratings (Top 10 Models)

!

| Model | Reliability Rating | Common Feedback |

|---|---|---|

| HX-500 | ★★★★★ | “Never fails, easy to maintain.” |

| TRX-1000 | ★★★★★ | “Industrial strength for big orders.” |

| KQ-FCUT | ★★★★☆ | “Switches between materials easily.” |

| ZT-BWC500 | ★★★★☆ | “Low fault rate, smart interface.” |

| RZ-CutPro | ★★★★☆ | “Great for long, precise runs.” |

| WP-AutoWrap | ★★★★☆ | “Reliable dual use saves space.” |

| SC-300 | ★★★★☆ | “Safety and strength in one.” |

| YS-PWM550 | ★★★★★ | “Superb performance in cleanrooms.” |

| JT-CW350 | ★★★★☆ | “Simple and dependable.” |

| PX-B350 | ★★★☆☆ | “Basic, but almost never fails.” |

Conclusion

The best bubble wrap cutting machine is the one that keeps running—day in, day out—with minimal upkeep and maximum uptime.

Insights

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we build machines with long-term performance in mind. Our HX-F350 Bubble Wrap Cutting Machine is not only affordable but engineered for durability and minimal maintenance. With CE/ISO certification, user-friendly design, and fast global delivery, we’ve helped clients like Mark Chen keep their production lines moving without stress. Whether you choose budget or premium, reliable machines come from manufacturers who understand your pain points—and solve them before they happen.

Explore this link to discover top-rated bubble wrap cutting machines that enhance efficiency and reliability. ↩

User feedback can provide real insights into machine performance and reliability, helping you make informed decisions. ↩

Understanding cutting precision can help you choose machines that maintain quality and reduce waste in packaging. ↩

Discover the benefits of dual-mode programming for versatile cutting applications in packaging. ↩

Explore the steps involved in conducting a diagnostic system check to maintain machine reliability. ↩